Manufacturing technique for refining native titanite

A production process and technology of ilmenite, applied in the field of beneficiation process of ilmenite concentrate, can solve the problems of large consumption of chemicals, complicated operation, high power consumption, improve yield and enrichment ratio, simplify process flow, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

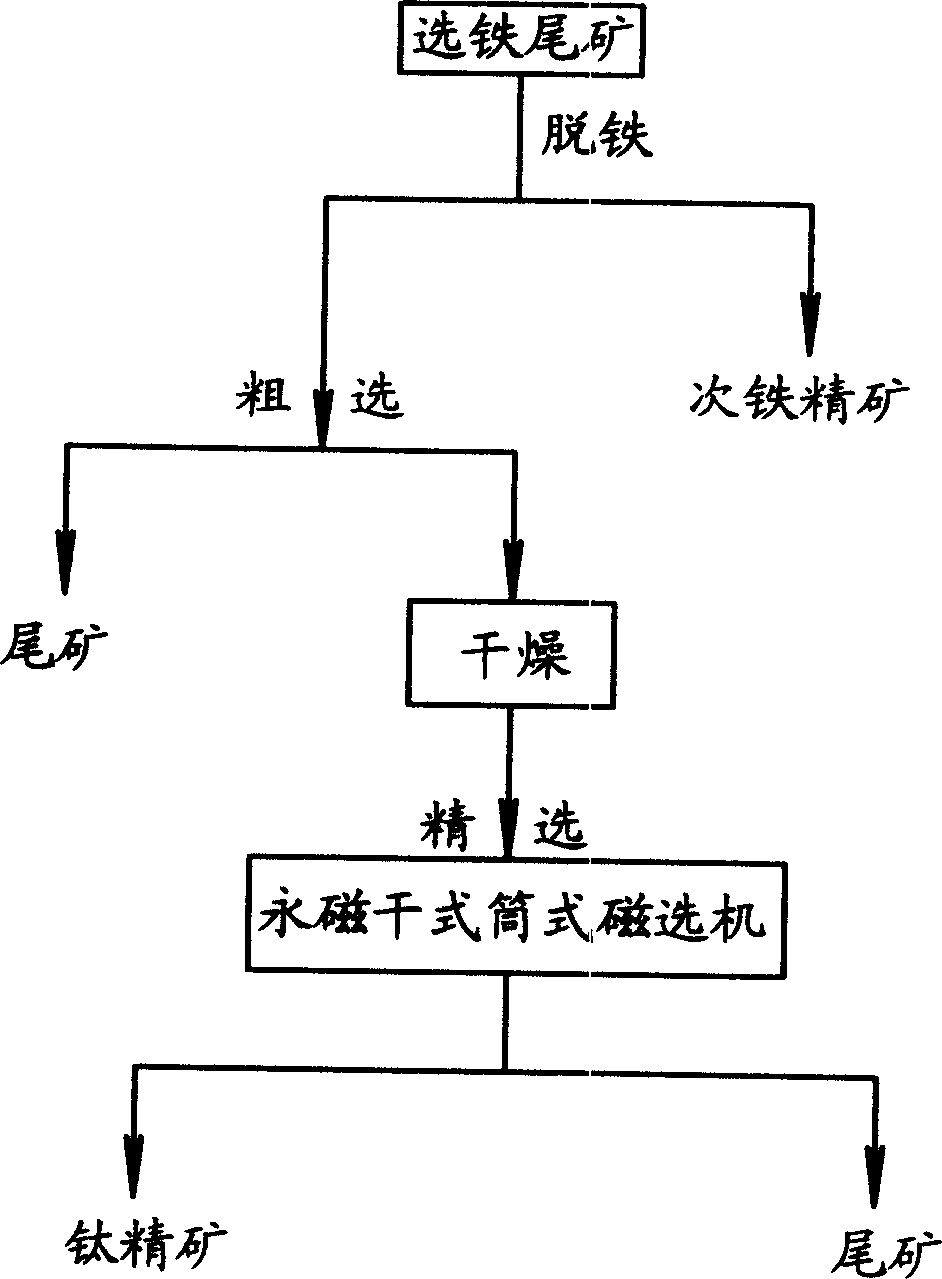

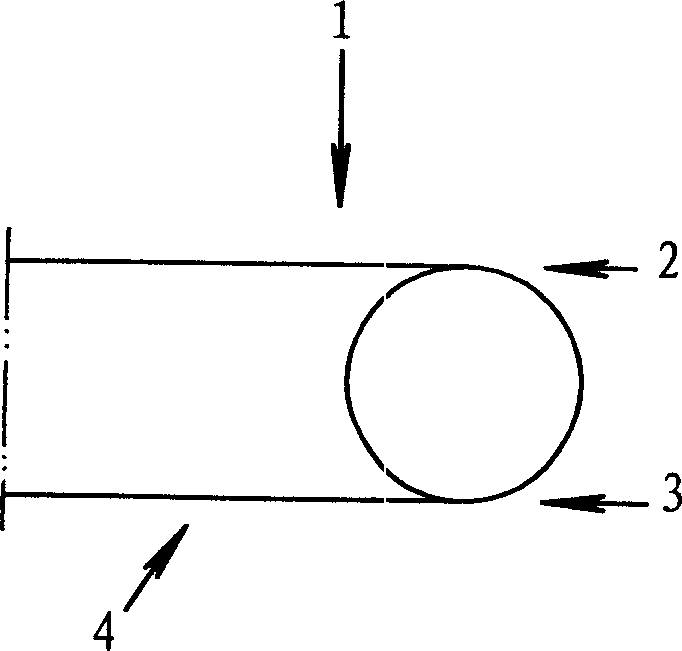

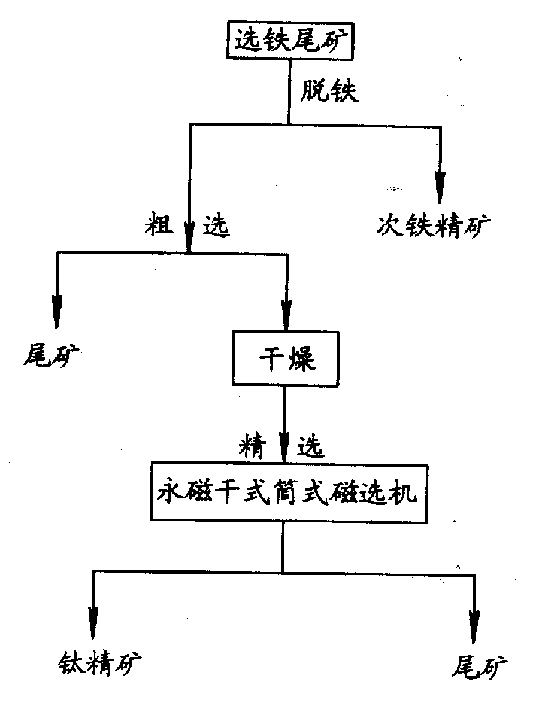

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment is that the production process of primary ilmenite ore of the present invention is used to process inclined plate grit (TiO 2 content is 9%). The particle size of the raw material is +0.074mm, and the aforementioned tailings TiO 2 Pre-enriched to 25%, dried, and then selected by a permanent magnetic dry drum magnetic separator (magnetic field strength is 0.7T) to obtain TiO 2 Qualified titanium concentrate with a content of 47.5%, final tailings TiO 2 The content is 5.4%.

Embodiment 2

[0029] The present embodiment is that the production process of primary ilmenite ore of the present invention is used to process the inclined plate overflow (TiO 2 content is 10%). The particle size of the raw material is +0.074mm, and the aforementioned tailings TiO 2 Pre-enriched to 20%, dried, and then selected by a permanent magnetic dry drum magnetic separator (magnetic field strength is 0.9T), to obtain TiO 2 Qualified titanium concentrate with a content of 48.2%, final tailings TiO 2 The content is 6.1%.

Embodiment 3

[0031] This embodiment is that the production process of the selected titanium concentrate of the present invention is used to process the spiral middle ore (TiO 2 content is 27%). The raw material is directly dried, and then selected by a permanent magnetic dry drum magnetic separator (the magnetic field strength is 0.7T) to obtain TiO 2 Qualified titanium concentrate with a content of 47.8%, final tailings TiO 2 The content is 4.80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com