Method for measuring shear strength of machinable ceramics

A technology of shear strength and ceramics, which is applied in the direction of testing material strength by applying stable shear force and testing material strength by applying stable tension/compression, which can solve the problem of stress concentration and homogeneous ceramic shear strength. Methods and other issues to achieve the effect of avoiding stress concentration, solving evaluation difficulties, and making sample preparation easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

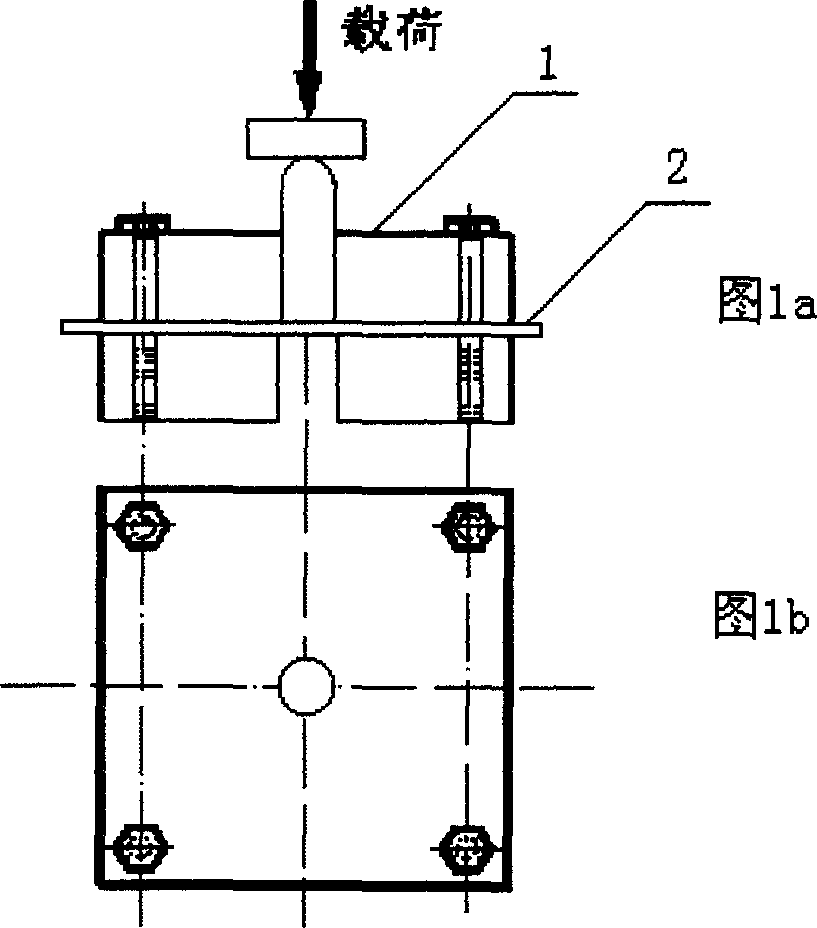

[0032] Embodiment 1: the thickness effect of pressing hole method

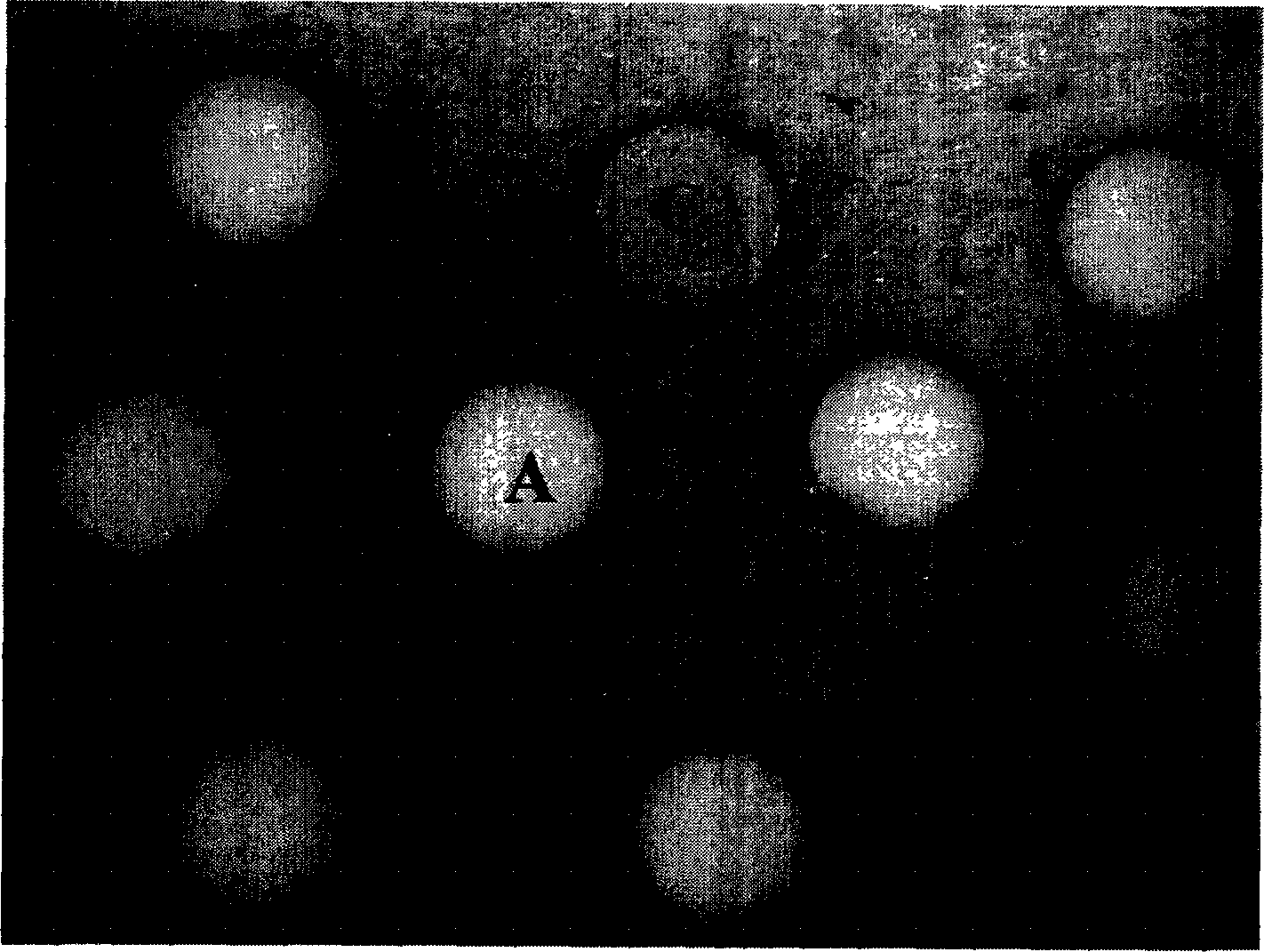

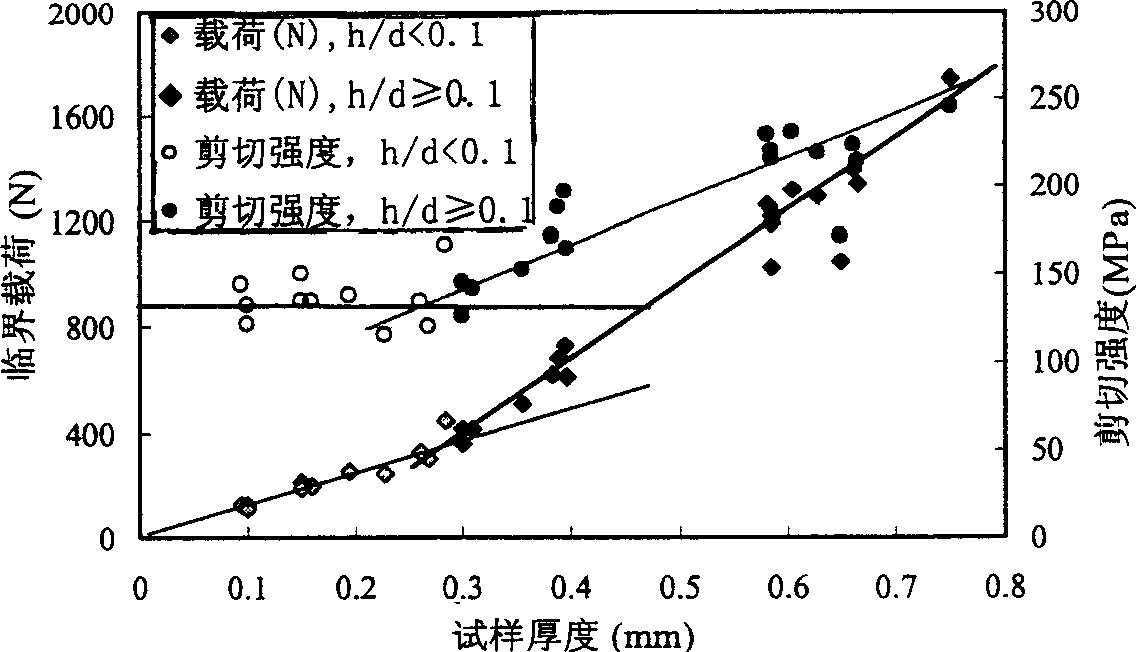

[0033] An advantage of the indentation shear test is that a simple laminar sample with no shape requirements can produce a range of experimental results, and the indentation shows a good shape with no crack branches. figure 2 Shown are punched samples and punched discs, marked with "A" are punched holes, marked with "B" are punched discs, figure 2 Shear failures that did not push out the disc are also shown, marked "C". The small disk "C" embedded in the sample has no obvious concavity, indicating a brittle failure with very little shear strain. Shear strength is generally considered to be a material constant, therefore, in equation (1), the ratio Pc / h of critical load to sample thickness should also be constant.

[0034] Pc=C·h h≤hc (2)

[0035] Here C is a constant. However, experiments have shown that this proportional relationship is only established when the thickness of the sample is ...

Embodiment 2

[0039] Example 2: Effect of loading rate and punch diameter

[0040] 0.24 mm thick Ti with various loading rates in the piercing shear test 3 AlC 2 The plate sample experiment, the results show that the loading rate has little effect on the experimental results. Figure 7 It is shown that the shear strength measured at various punch speeds from 0.05 mm / min to 5 mm / min is substantially at the same level. The reason may be that machinable ceramics have a slow subcritical crack growth rate, so they are not sensitive to the loading rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com