Alar electromagnetic hardening method

An aluminum-silicon alloy and aluminum-silicon-based technology, which is applied in the field of electromagnetic quenching and tempering of aluminum-silicon alloys, can solve problems such as inability to apply, unstable effect, etc., and achieve the effects of easy mastery, simple operation, and simple quenching and tempering method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Take A356 alloy billet as raw material, put it into a resistance furnace and heat it, the melting temperature is 800°C, set the number of turns of the electromagnetic coil to 100 turns, the speed of the casting machine is 130mm / min, the frequency of the magnetic field is determined to be 30Hz, and the current intensity is 10000 ampere-turns , when the casting temperature is 720 ℃, the ingot is obtained by horizontal continuous casting.

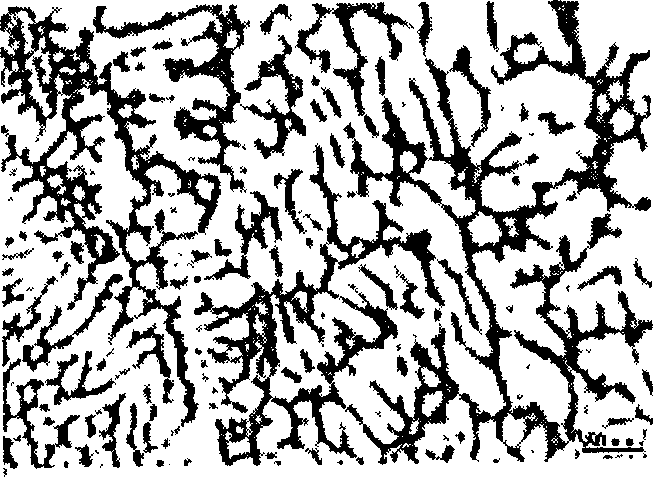

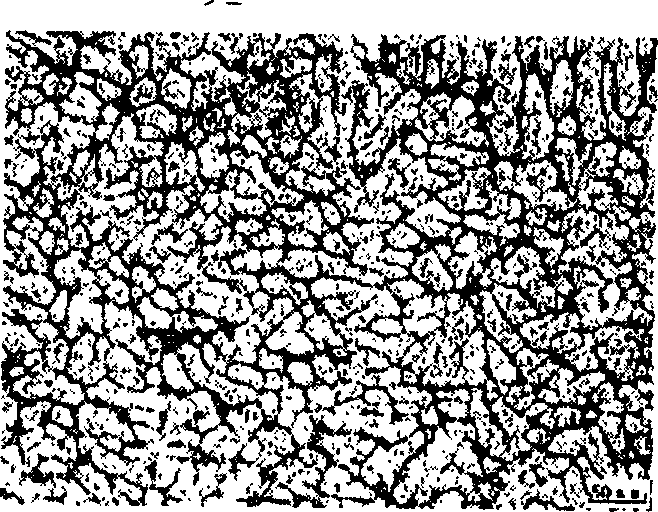

[0029] The results are compared to figure 1 , figure 2 Shown:

[0030] (1) Comparing low-frequency electromagnetic casting with casting without low-frequency electromagnetic field, it is concluded that low-frequency electromagnetic casting can refine grains and obtain fine α-Al structure and eutectic structure.

[0031] (2) Applying a low-frequency electromagnetic field can increase the intragranular content of silicon in aluminum, narrow the eutectic region and grain boundaries, and make the distribution of silicon more u...

example 2

[0032] Example 2: Lay silicon particles (particle size 10-40mm) on the bottom of a graphite crucible, press it with pure aluminum blocks, heat up to 900°C, melt the aluminum and keep it warm for 3 hours, fully stir to completely dissolve the silicon in the aluminum solution . The number of turns of the electromagnetic coil is set to 100 turns, the speed of the casting machine is 100mm / min, the frequency of the magnetic field is determined to be 50Hz, the strength of the magnetic field is 15000 ampere-turns, and the casting temperature is 710°C, and the ingot is obtained by horizontal continuous casting.

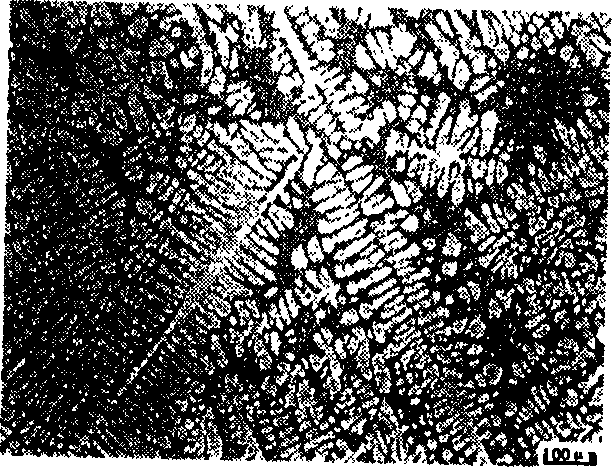

[0033] The results are compared to image 3 , Figure 4 , Figure 5 , Figure 6 Shown:

[0034] (1) The α-Al dendrites without electromagnetic field are coarse and uneven; the α-Al dendrites with electromagnetic field are fine and uniform.

[0035] (2) The grain size of eutectic Si without electromagnetic field is large and uneven, and some parts grow in clusters; the gr...

example 3

[0036] Example 3: Using Al-20Si master alloy as raw material, heat to 1000°C and keep it warm for 30min. The number of turns of the electromagnetic coil is set to 100 turns, the speed of the casting machine is 70mm / min, the magnetic field frequency is determined to be 15Hz, the current intensity is 20,000 ampere-turns, and the casting temperature is 840°C, and the ingot is obtained by horizontal continuous casting.

[0037] The results are compared to Figure 7 , Figure 8 Shown:

[0038] (1) For hypereutectic Al-Si alloys, low-frequency electromagnetic casting can refine primary silicon particles and change their morphology.

[0039] (2) Electromagnetic casting can significantly refine the eutectic structure of hypereutectic Al-Si alloy, resulting in significant modification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com