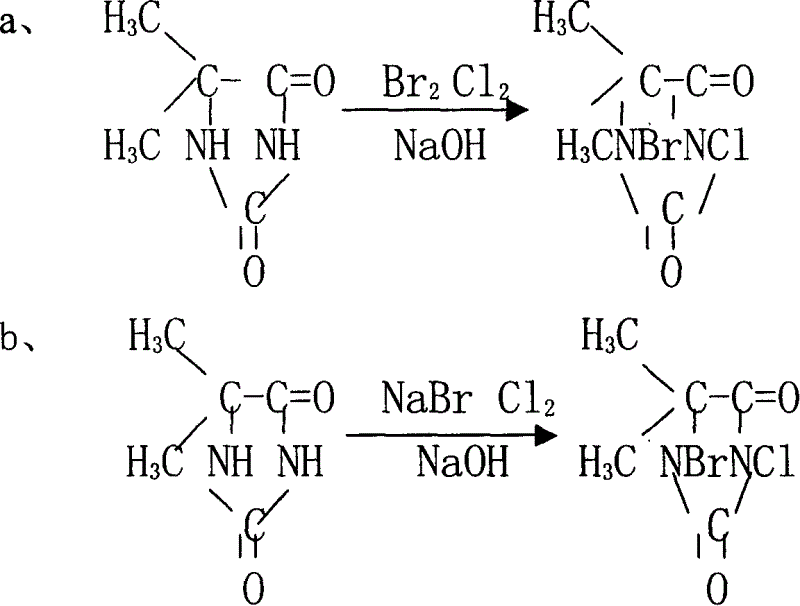

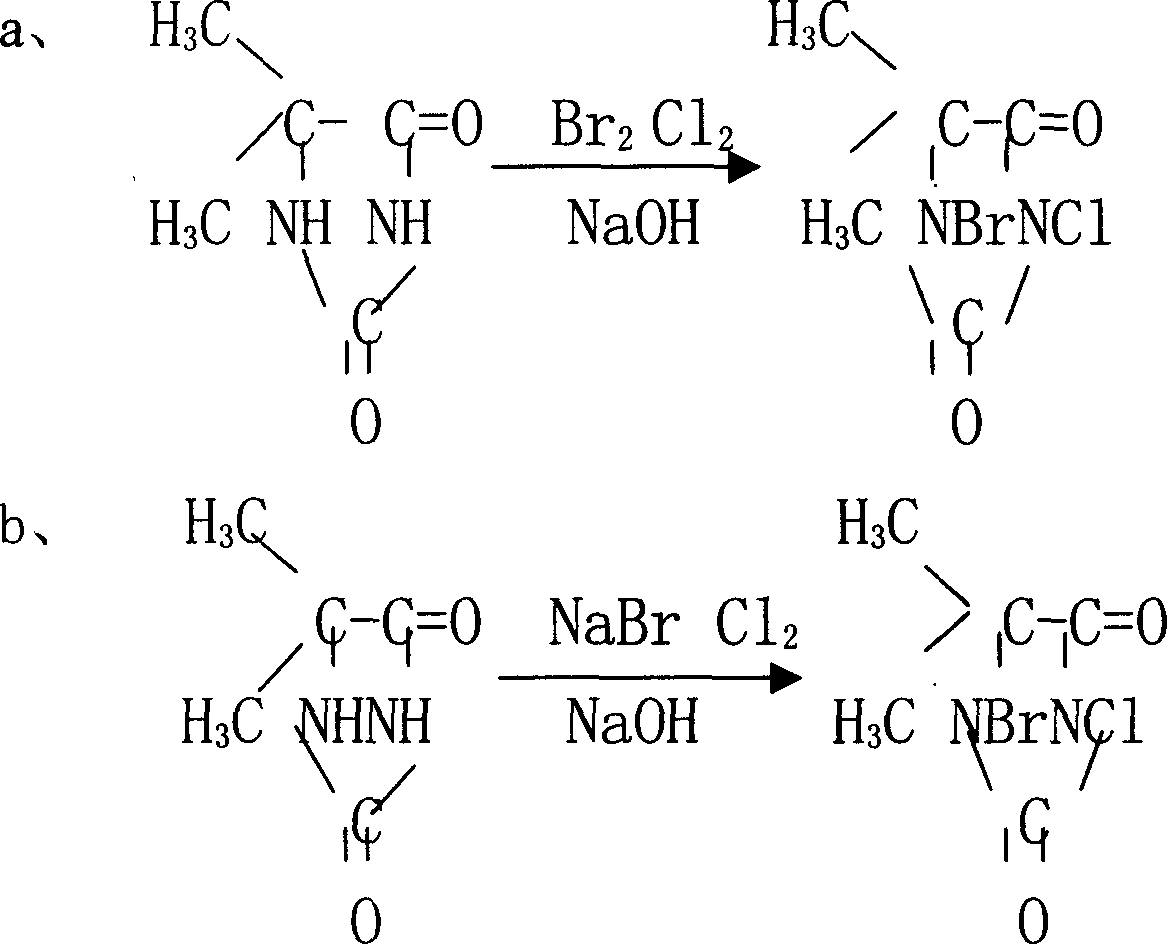

Bromochloro glucolylurea steribizing and disinfecting algae cide preparing method

A technology of bactericidal algicide and bromochlorohydantoin, which is applied in the fields of botanical equipment and methods, biocides, animal repellents, etc., can solve the problems of low product purity, high cost, low yield, etc., and achieves operational control. Simple, low waste water discharge and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 140Kg of dimethyl hydantoin and 1080Kg of water into a 2000-liter glass-lined reactor, stir at room temperature for 15 minutes, then control the temperature at 5°C, and simultaneously add 134Kg of 34.5% sodium hydroxide solution in proportion to the online metering device, Add bromine 90Kg dropwise, after sodium hydroxide and bromine pass through, continue to stir and react for 30 minutes at 5°C, then control the temperature at 3°C, and add 122Kg of 34.5% sodium hydroxide dropwise in proportion through an online metering device at the same time, pass through Chlorine 117Kg, when the sodium hydroxide is dripped, the remaining chlorine is 5Kg, and continue to drip, then still stir and react at 3°C for 40 minutes, then send the reaction material to a centrifuge for separation, then wash with 110Kg water, shake it off, and leave it at 60 Dried at -80°C to obtain 253Kg of white powder crystalline bromochlorohydantoin, with a yield of 96.2% and a purity of 99.2%; The re...

Embodiment 2

[0016] Add 140Kg of dimethylhydantoin and 1080Kg of water into a 2000-liter glass-lined reactor, stir at room temperature for 15 minutes, then control the temperature at 12°C, and simultaneously add 130Kg of 35.5% sodium hydroxide solution in proportion to the online metering device, Add 90Kg of bromine dropwise. After the alkali and bromine have passed through, continue to stir the reaction for 30 minutes at 12°C, then control the temperature at 10°C, and add 118Kg of 35.5% sodium hydroxide dropwise in another proportion through an online metering device, and pass Chlorine 117Kg, when dripping alkali, residual chlorine 5Kg, and continue to pass through, then still stirred and reacted at 10 ℃ for 40 minutes, and the reaction ended. Send the reaction materials to a centrifuge for separation, wash them with 110Kg of water, shake them off, and dry them at 60-80°C to obtain 253Kg of white powder crystal bromide chlorohydantoin, with a yield of 96.2% and a purity of 99.2%; Add 140K...

Embodiment 3

[0018] Add 140Kg of dimethyl hydantoin and 1080Kg of water into a 2000-liter glass-lined reactor, stir at room temperature for 15 minutes, then control the temperature at 9°C, and simultaneously add 132Kg of 35% sodium hydroxide solution in proportion to the online metering device, Add 90Kg of bromine dropwise. After the alkali and bromine are passed through, continue to stir the reaction for 30 minutes at 9°C, then control the temperature at 3-10°C, and add 120Kg of 35% sodium hydroxide dropwise in another proportion through the online metering device , logical chlorine 117Kg, when dripping alkali, remaining chlorine 5Kg, and continue to logically complete, then still stir reaction at 9 ℃ for 40 minutes, and reaction finishes. Send the reaction materials to a centrifuge for separation, wash them with 110Kg of water, shake them off, and dry them at 60-80°C to obtain 253Kg of white powder crystal bromide chlorohydantoin, with a yield of 96.2% and a purity of 99.2%; Add 140Kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com