Damage-free and non-contact analysis system

A non-contact analysis, a series of technologies, applied in the direction of non-contact circuit testing, material analysis, material analysis through electromagnetic means, etc., can solve problems such as difficult to distinguish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

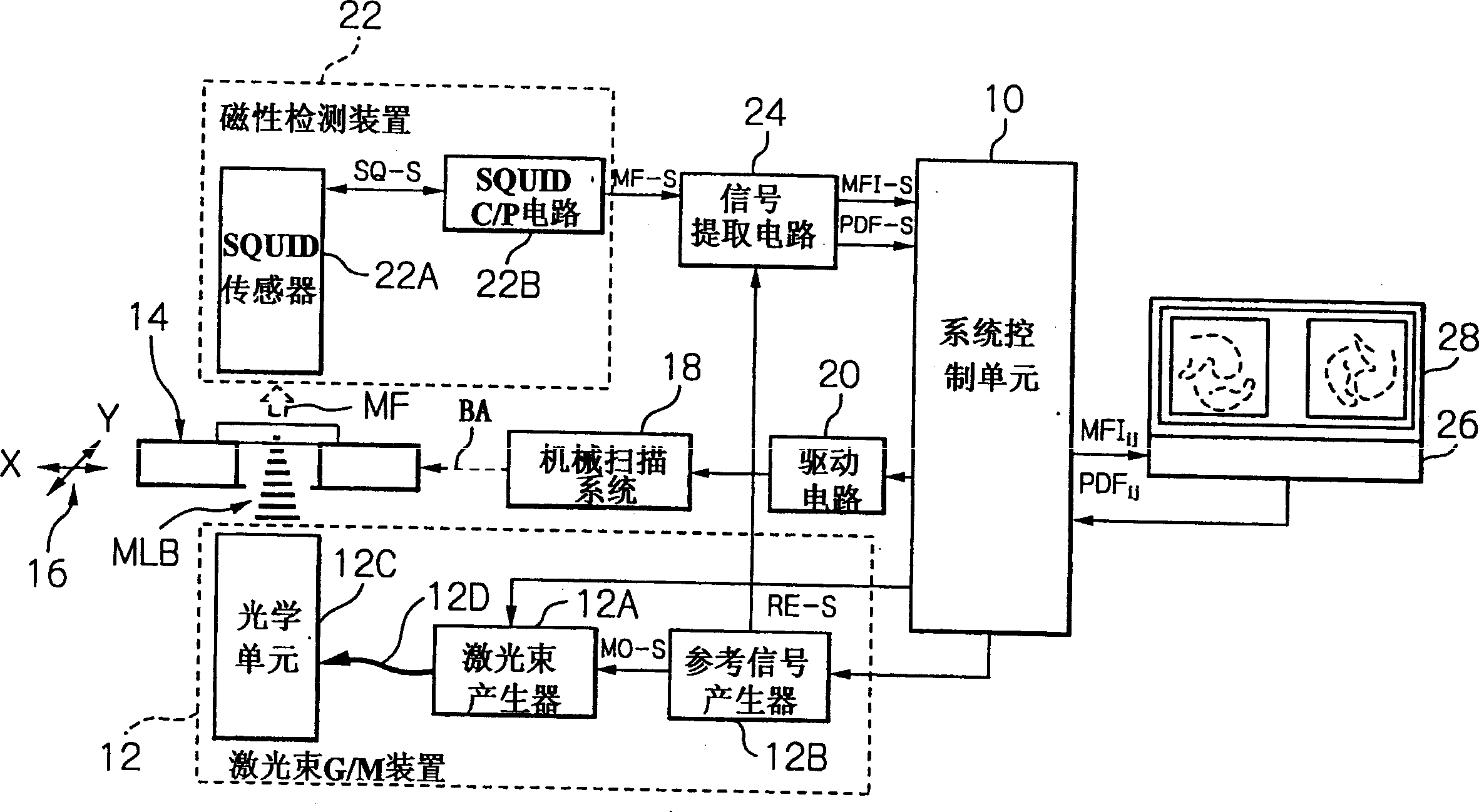

[0067] refer to Figures 1 to 3 , an embodiment of the non-destructive non-contact analysis system according to the present invention will be described below.

[0068] The non-destructive non-contact analysis system is used to analyze and evaluate an object to be analyzed and evaluated, such as a silicon wafer, in which an electric current can be excited when irradiated with a laser beam. Note that this current is known in the art as OBIC (Beam Incentive Current), as already explained.

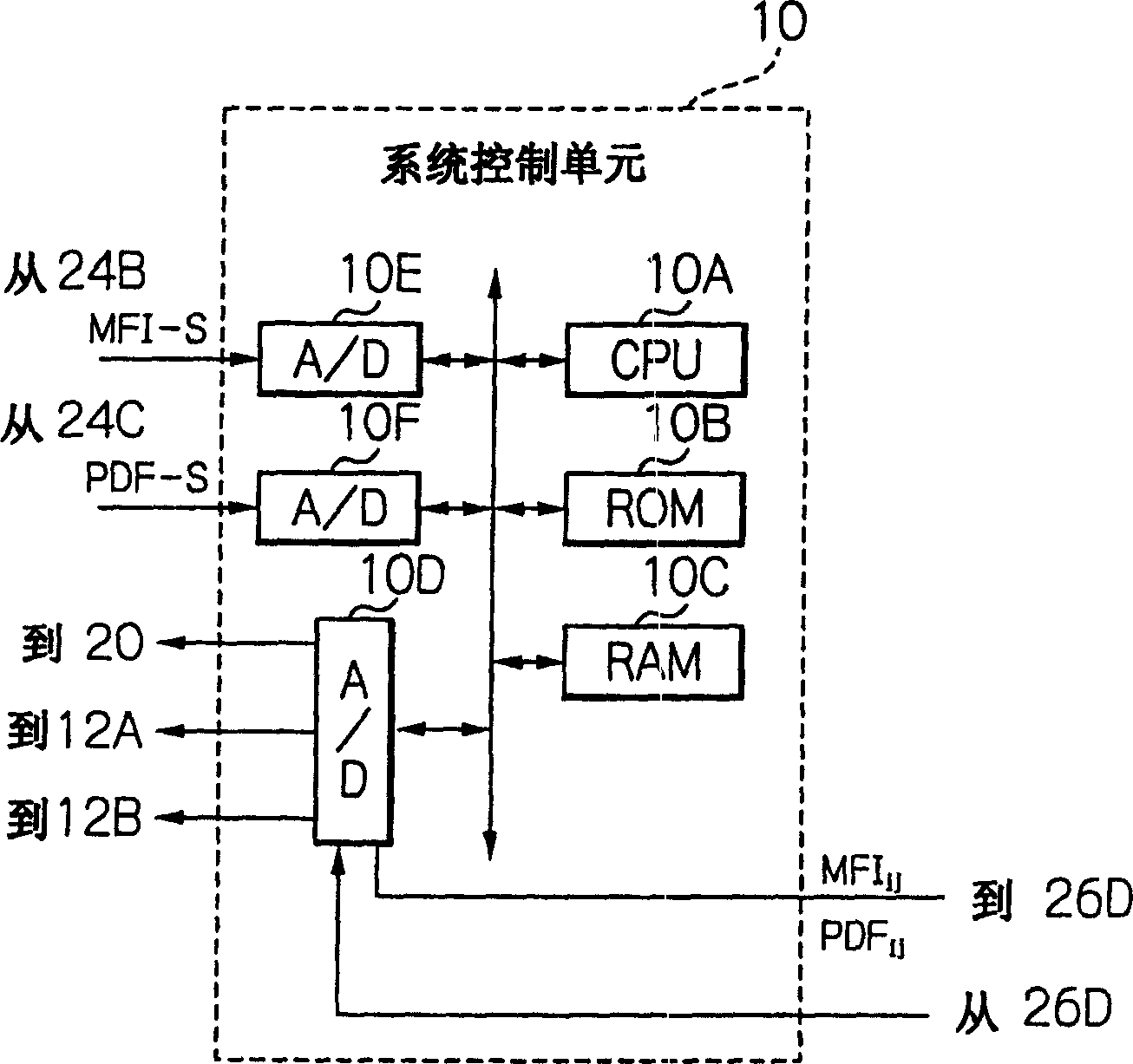

[0069] The non-destructive non-contact analysis system comprises a system control unit 10, which is structured as figure 2 microcomputer shown. That is, the system control unit 10 includes a central processing unit (CPU) 10A, a read only memory (ROM) 10B for storing various programs and constants, a random access memory (RAM) 10C for storing temporary data, input an output (I / O) interface circuit 10D, and two analog-to-digital (A / D) converters 10E and 10F.

[0070] Also, the non-destructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com