Enhanced acid dissolve of acidizing fired slags of concentrated gold ores containing sulfur

A technology of sulfuration roasting and gold concentrate, which is applied in the direction of improving process efficiency and can solve the problem of low extraction rate of gold concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

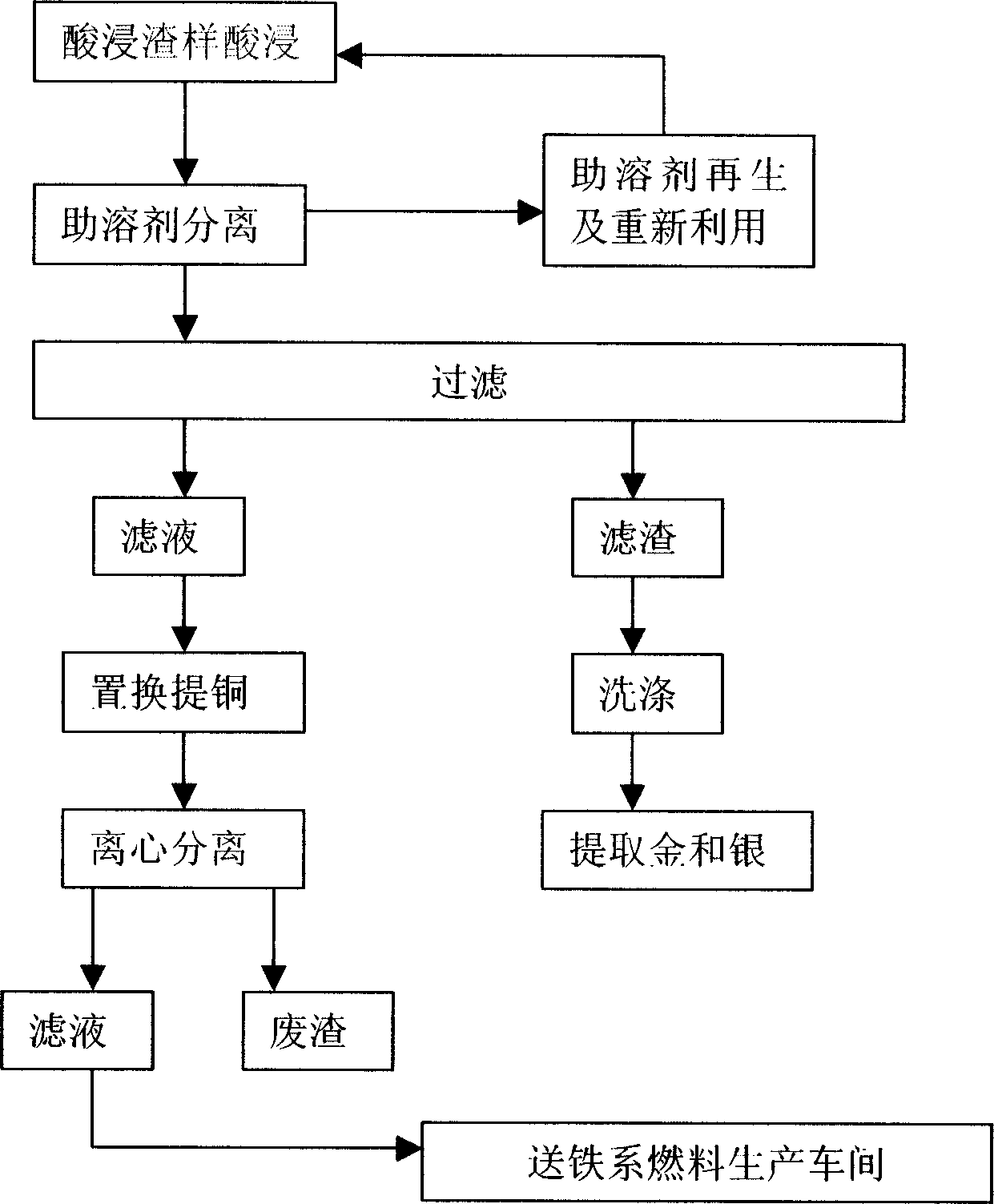

Method used

Image

Examples

Embodiment 1

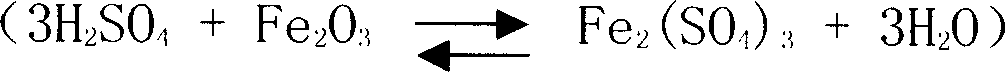

[0020] Add 60% sulfuric acid into the reaction kettle with agitator, start the agitator to stir, and add roasted slag at one time, the weight percentage of sulfuric acid solution and roasted slag is 1: 2, and the weight percentage of cosolvent and roasted slag is 1: 1. Diethylaminetetraacetic acid (EDTA), CuO, Fe in the solvent 2 o 3 , SiO 2 、Al 2 o 3 The proportioning ratio is 1%, 85%, 5%, 4%, 5%, the reaction temperature is 80°C, and the reaction time is 6 hours. According to the national standard, the iron leaching rate is 100%, and the gold and silver extraction rate is 98%.

Embodiment 2

[0022] Add 30% sulfuric acid into the reaction kettle with agitator, start the agitator to stir, add roasted slag at one time, the weight percentage of sulfuric acid solution and roasted slag is 1: 10, and the weight percentage of cosolvent and roasted slag is 1: 50. Diethylaminetetraacetic acid (EDTA), CuO, Fe in the solvent 2 o 3 , SiO 2 、Al 2 o 3 The proportioning ratio is 1%, 80%, 10%, 4%, 5%, the reaction temperature is 100°C, and the reaction time is 4 hours. According to the national standard, the leaching rate of iron is 100%, and the gold extraction rate of gold and silver is 98%.

Embodiment 3

[0024] Add 45% sulfuric acid in the reaction kettle with agitator, start the agitator to stir, add roasted slag at one time, the weight percentage of sulfuric acid solution and roasted slag is 1: 5, and the weight percentage of cosolvent and roasted slag is 1: 5. Diethylaminetetraacetic acid (EDTA), CuO, Fe in the solvent 2 o 3 , SiO 2 、Al 2 o 3 The proportions are 0.5%, 85%, 10.5%, 4%, 5%, the reaction temperature is 90°C, and the reaction time is 5 hours. According to the national standard, the leaching rate of iron is 100%, and the gold extraction rate of gold and silver is 98%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com