Preparing nano sheet type polymer using LDHs as template and its preparing method

A nano-sheet, polymer technology can solve the problems of difficult control, low output and high cost, and achieve the effects of less influencing factors on polymerization, widening the selection range, and easy control of polymerization conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

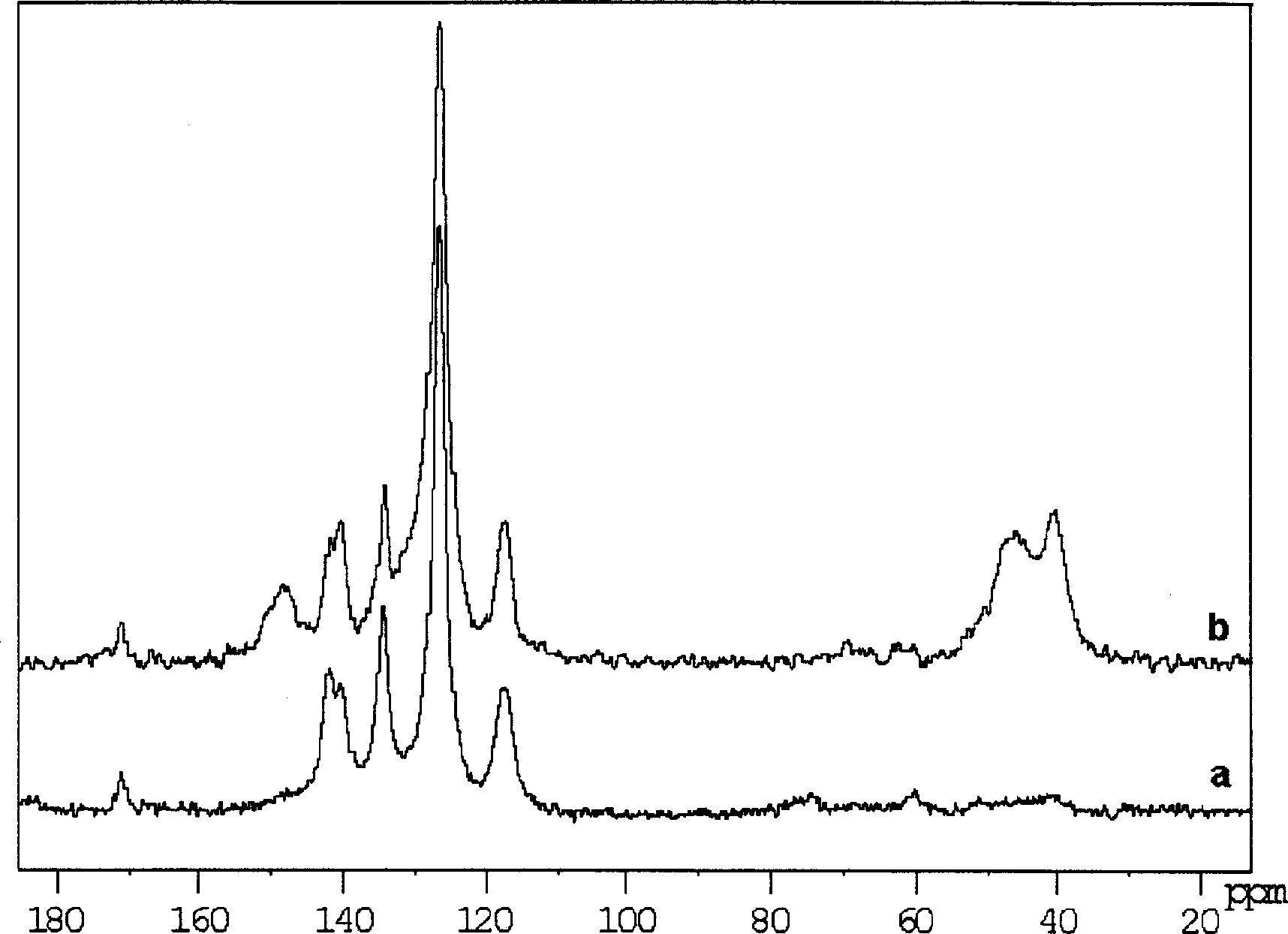

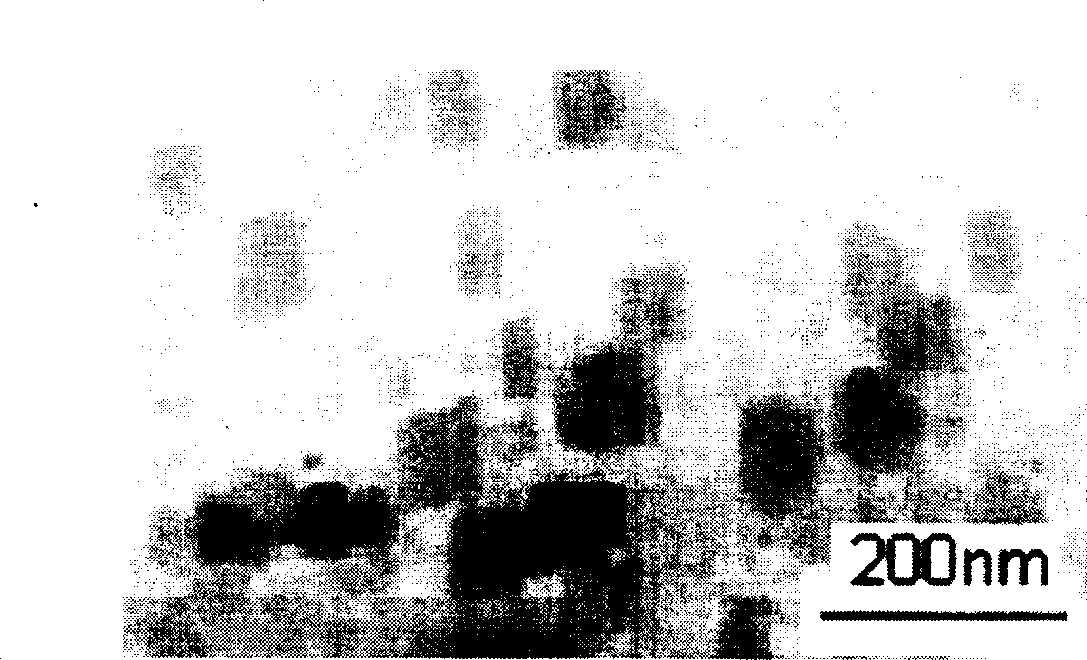

Image

Examples

Embodiment 1

[0027] A. Mg(NO 3 ) 2 (0.15mol, 38.46g), Al(NO 3 ) 3 (0.075mol, 28.13g) The Mg / Al molar concentration ratio is equal to 2 and 187.5ml of nitrogen-purified deionized water is used to make a salt solution.

[0028] B. Mix NaOH (0.42mol, 17.28g) with 150ml of nitrogen-purified deionized water to form an alkaline solution.

[0029] C. Mix 0.084mol (15.45g) monomer sodium 4-vinylbenzene sulfonate (sodium p-styrene sulfonate abbreviated as SSS) with 187.5ml nitrogen-purified deionized water into a solution.

[0030] D. Under the protection of nitrogen, add the solutions obtained in steps B and C into a four-neck flask, and then add the mixed salt solution obtained in step A into the four-neck flask under vigorous stirring, and add dropwise to pH= Stop at 10 o'clock, crystallize at 50°C for 10 hours, then filter, wash with water to pH less than 8, and dry at 65°C for 24 hours to obtain the template—the hydrotalcite LDHs-SS with the interlayer guest being the monomeric SSS intercalated an...

Embodiment 2

[0036] A. Mg(NO 3 ) 2 (0.3mol, 76.8g), Al(NO 3 ) 3 (0.15 mol, 56.5 g) was used to prepare a salt solution with 250 ml of nitrogen purified deionized water.

[0037] B. Mix NaOH (0.9mol, 36g) with 375ml of nitrogen-purified deionized water to form an alkaline solution.

[0038] C. Dissolve 32g of NaOH in 350ml of deionized water, add 55ml of CH 2 =CHCOOH (acrylic acid abbreviated as AA) was added dropwise to the solution, adjusted to pH=7, and prepared into a 2M AANa solution.

[0039] D. Under the protection of nitrogen, add the solutions obtained in step B and step C into a four-neck flask, and add the mixed salt solution of step A into the four-neck flask dropwise under vigorous stirring, and add dropwise to pH=9.5 When stopped, crystallized at 65°C for 40h, filtered, washed with water to pH less than 8, and dried at 70°C for 20h to obtain LDHs-AA template. XRD and IR are used to prove that the monomer has been intercalated and assembled into the interlayer of hydrotalcite. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com