Organic silicon modified polyurethane gap-filling rubber for cement road

A technology of silicone and polyurethane, which is applied in polyurea/polyurethane adhesives, roads, roads, etc., can solve the problems of polyurethane gap fillers such as poor weather resistance, poor embedding resistance, and poor oil resistance, and achieve superior cost performance and overcome mechanical problems. The effect of poor performance and good low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

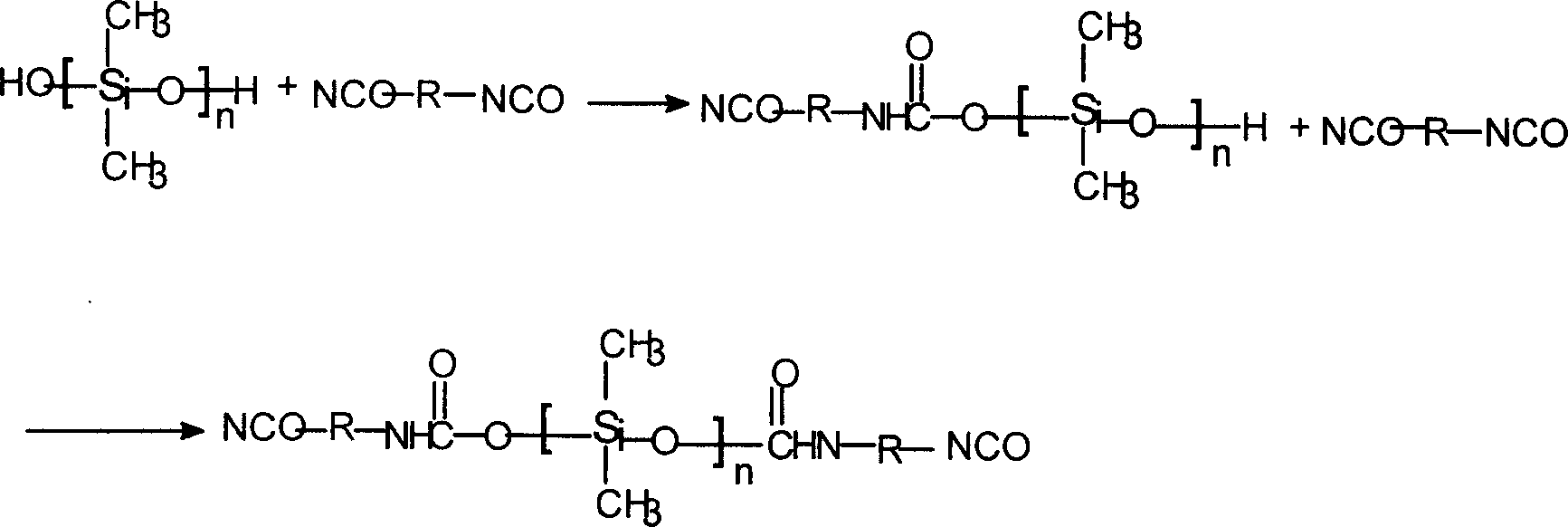

Method used

Image

Examples

Embodiment 1

[0037] (1) 110g molecular weight is the polyoxypropylene diol of 2000 hydroxyl value 54-58mgKOH / g, 130g molecular weight is 3050, the polyoxypropylene triol of hydroxyl value 54.5-57.5, 0.5g benzoyl chloride and 72g degree of polymerization Add 5-7 hydroxyl-terminated polydimethylsiloxane into a dry and clean reactor.

[0038] (2) Under the vacuum degree of about -0.086MP, turn on the stirring and turn on the condensed water of the condenser. Maintain the material temperature at about 90°C and dehydrate for 2 hours. When almost no water comes out from the condenser, close the intake valve and cool down to 60°C.

[0039] (3) Add 56g TDI for pre-polymerization reaction, under stirring, control the temperature in the reactor at 40-60°C, slowly add TDI, be sure to strictly control the temperature when adding TDI, and never exceed 70°C (a lot of heat will be generated after adding , pay attention to control the intake switch, and strictly control the temperature. Otherwise, the t...

Embodiment 2

[0043] (1) 150g molecular weight is the polyoxypropylene diol of 4000 hydroxyl value 26-30mgKOH / g, 120g molecular weight is the polyoxypropylene triol of 3000 hydroxyl value 54-58mgKOH / g, 0.5g benzoyl chloride and 30g polymerization The hydroxyl-terminated polydimethylsiloxane with a degree of 8-10 is added to the previously dried and cleaned reactor.

[0044] (2) Under the vacuum degree of about -0.086MP, turn on the stirring and turn on the condensed water of the condenser. Maintain the material temperature at about 90°C and dehydrate for 2 hours. When almost no water comes out from the condenser, close the intake valve and cool down to 60°C.

[0045] (3) Add 90g of MDI to carry out prepolymerization reaction. Under stirring, control the temperature in the reactor at 40-60°C, and slowly add MDI. When adding MDI, be sure to strictly control the temperature and never exceed 70°C. While stirring for 30 minutes, slowly raise the temperature to 80-82° C., maintain this temperat...

Embodiment 3

[0049] (1) 61g molecular weight is the polyoxypropylene diol of 1000 hydroxyl value 105-117mgKOH / g, 110g molecular weight is the polyoxypropylene triol of 3050 hydroxyl value 51, 0.5g benzoyl chloride and 48g degree of polymerization is 11- 13 hydroxy-terminated polydimethylsiloxane was added to the dry and clean reactor.

[0050] (2) Under the vacuum degree of about -0.086MP, turn on the stirring and turn on the condensed water of the condenser. Maintain the material temperature at about 90°C and dehydrate for 2 hours. When almost no water comes out from the condenser, close the intake valve and cool down to 60°C.

[0051] (3) Add 60g of PAPI for pre-polymerization reaction, under stirring, control the temperature in the reactor at 40-60°C, slowly add PAPI, be sure to strictly control the temperature when adding PAPI, and never exceed 70°C. While stirring for 30 minutes, slowly raise the temperature to 80-82° C., maintain this temperature range, and conduct polymerization u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com