Method and device for producing alloy powder for permanent magnet

A technology of alloy powder and permanent magnet, which is used in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc., can solve the problems of cumbersome, complicated management of large-scale devices, and no records, and achieves improved productivity and control characteristics. Deterioration and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

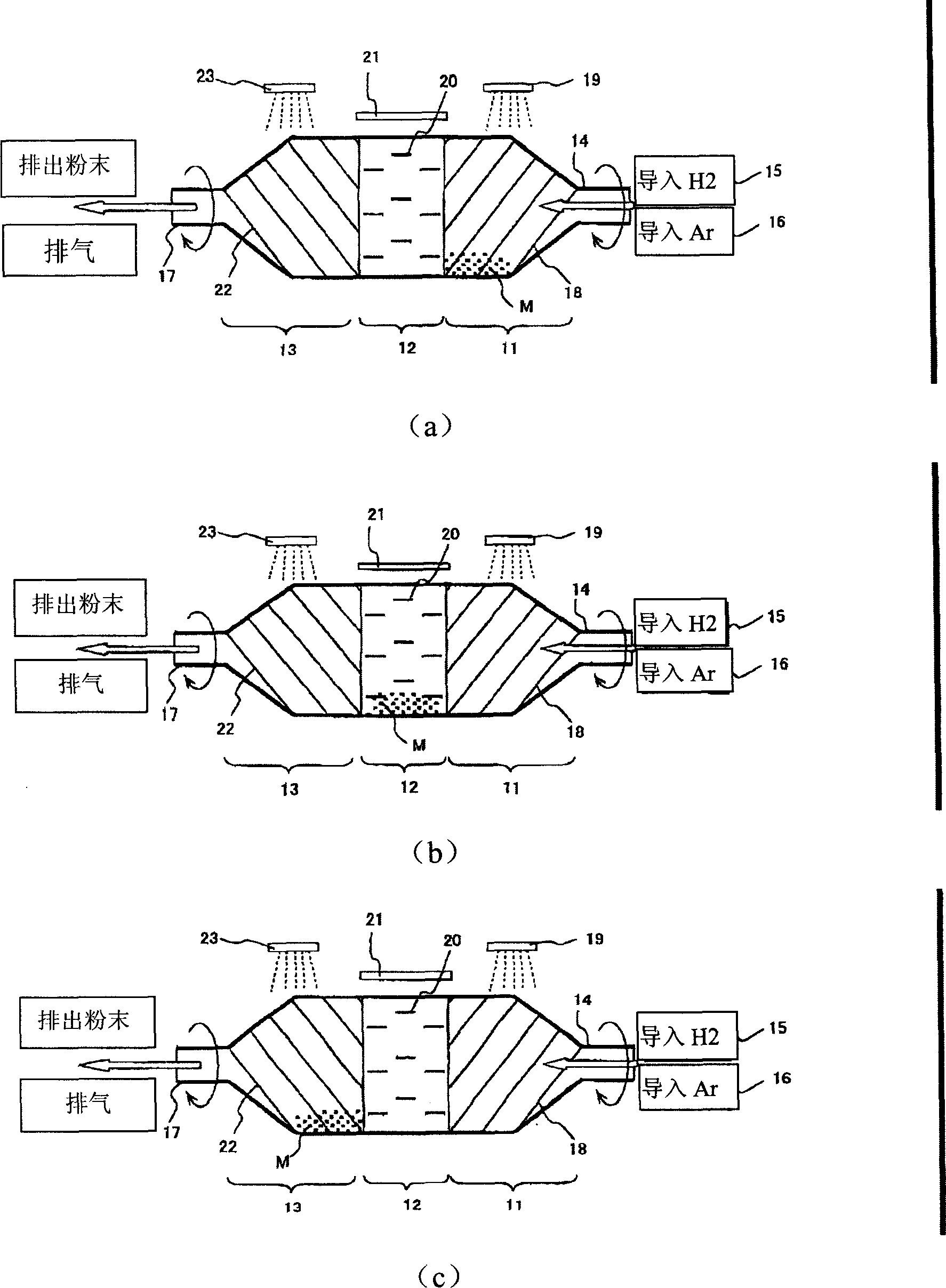

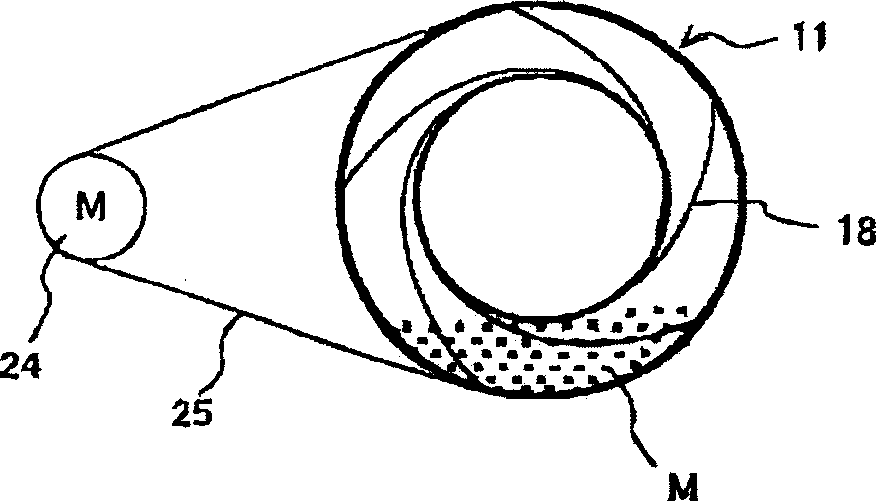

[0033] The apparatus and method for producing alloy powder for permanent magnets to which the present invention is applied will be described in detail below with reference to the drawings.

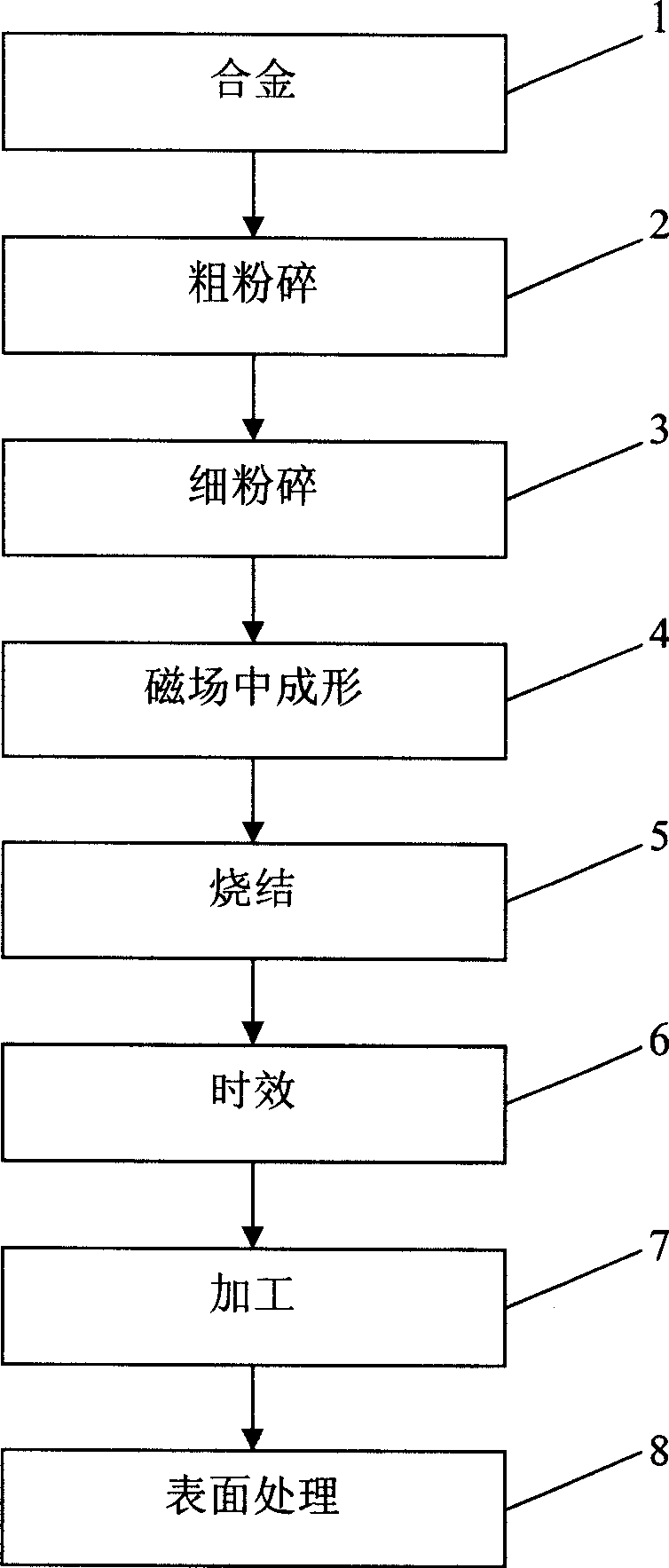

[0034] In the production apparatus and production method of the present invention, the alloy powder for permanent magnets to be produced is used in the production of rare earth sintered magnets. Therefore, first, the rare earth sintered magnet and its manufacturing method will be briefly described as follows.

[0035] The main components of rare earth sintered magnets are rare earth elements, transition metal elements and boron elements. Here, the magnet composition (alloy composition) can be arbitrarily selected according to the purpose. For example, R-T-B (R refers to one or more than two rare earth elements, wherein the rare earth metals include Y. T is one or more than two transition metals with Fe or Fe and Co as essential components, and B is boron element.) Rare-earth sintered mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com