Method for establishing a movable temperature controlling animals/birds slaughtering and deep-processing factory and its application

A technology for processing plants and meat, which is applied in poultry slaughtering, meat processing, and livestock fields. It can solve the problems of waste of transportation capacity, high death and weight consumption, increase transportation costs and transportation links, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

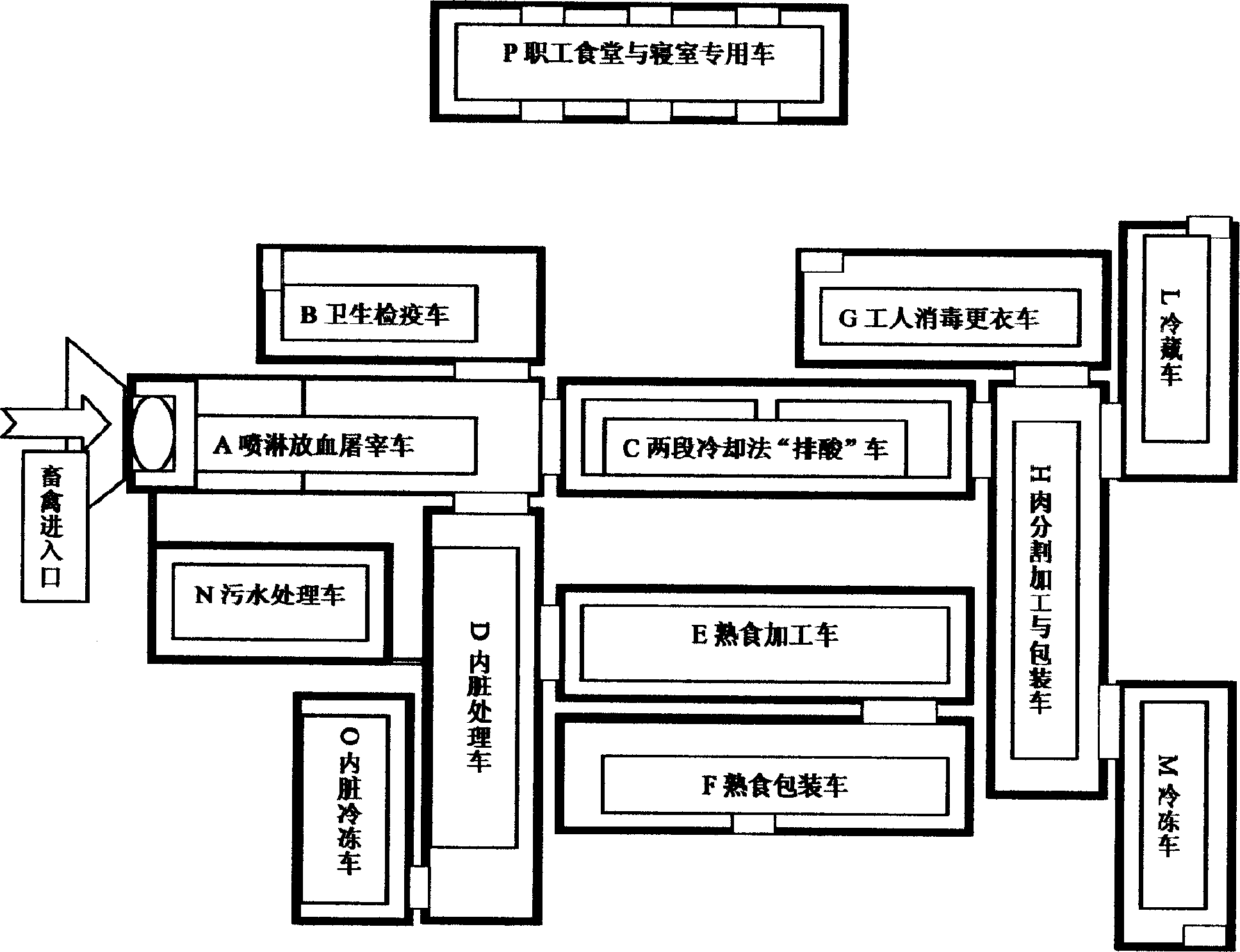

[0150] The present invention will be further described in conjunction with accompanying drawings and the slaughtering and deep processing of sheep.

[0151] First of all, a series of equipment for slaughtering and further processing sheep were installed in the figure 1 Among the special vehicles shown, a professional sheep slaughtering and processing plant with temperature control is formed. The functions of each vehicle and the installation and connection of equipment are briefly explained below:

[0152] A spray bloodletting slaughter vehicle:

[0153] The interior of the car is divided into four areas, which are installed with spray cleaning device, vacuum bloodletting and slaughtering device, skin peeling machine and hanging transmission device. The air conditioner in the hanging transmission area is set at 10-15°C.

[0154] The vacuum bloodletting and slaughtering device, the skinning machine and the hanging transmission device are synchronously inspected and connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com