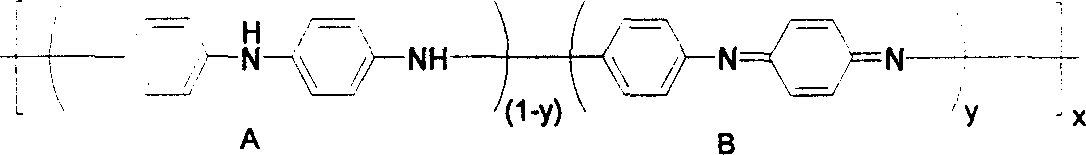

Process for preparing polyaniline film on electroplated zinc steel plates through electric polymerization

A technology of polyaniline film and process method, which is applied in the direction of electrophoretic plating, electrolytic paint, coating, etc., can solve the problems of electropolymerized polyaniline film, etc., and achieve the effects of favorable environmental protection, simple equipment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: In 0.2mol / L aniline, 0.5mol / L sodium salicylate aqueous solution, adjust to PH=6.5 with hydrochloric acid, use constant potential method to polymerize aniline in ice-water bath, constant potential voltage is 1.7V, polymerization time for 60s, and then heat treatment at 200°C for 20 minutes, and finally a layer of polyaniline film can be coated on the electro-galvanized steel sheet.

[0020] For the electro-galvanized steel plate coated with electropolymerized polyaniline film, according to the GB6458-86 standard, a neutral salt spray test is carried out: the appearance time of white rust is 10 hours.

Embodiment 2

[0021] Embodiment two: in 0.5mol / L aniline and 1mol / L sodium salicylate aqueous solution, adjust to PH=6.0 with sulfuric acid, use potentiostatic method to polymerize aniline in ice-water bath, constant potential voltage is 1.5V, polymerization time is 120s, and then heat treatment at 200°C for 40 minutes, and finally a layer of polyaniline film can be coated on the electro-galvanized steel sheet.

[0022] For the electro-galvanized steel plate coated with electropolymerized polyaniline film, refer to the GB6458-86 standard. Conduct a neutral salt spray test: the appearance time of white rust is 9 hours.

Embodiment 3

[0023] Embodiment three: in 0.2mol / L aniline and 0.5mol / L sodium salicylate aqueous solution, adjust to PH=6.5 with hydrochloric acid, use constant current method to polymerize aniline in ice-water bath, the current density of constant current method is 10mA / cm 2 , the polymerization time is 60s; then heat treatment is carried out at 200°C for 30 minutes; finally, a layer of polyaniline film is coated on the electro-galvanized steel sheet;

[0024] For the electro-galvanized steel plate coated with electropolymerized polyaniline film, according to the GB6458-86 standard, the neutral salt spray test was carried out, and the white rust appeared for 11 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com