Method for the production of a siderurgical product made of carbon steel with a high copper content, and siderurgical product obtained according to said method

A technology of steel products and carbon content, which is applied in the manufacture of steel and iron-based alloys, and can solve problems such as not giving details of steel plate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] First, a liquid metal having the following composition (all contents are expressed in weight percent) was produced.

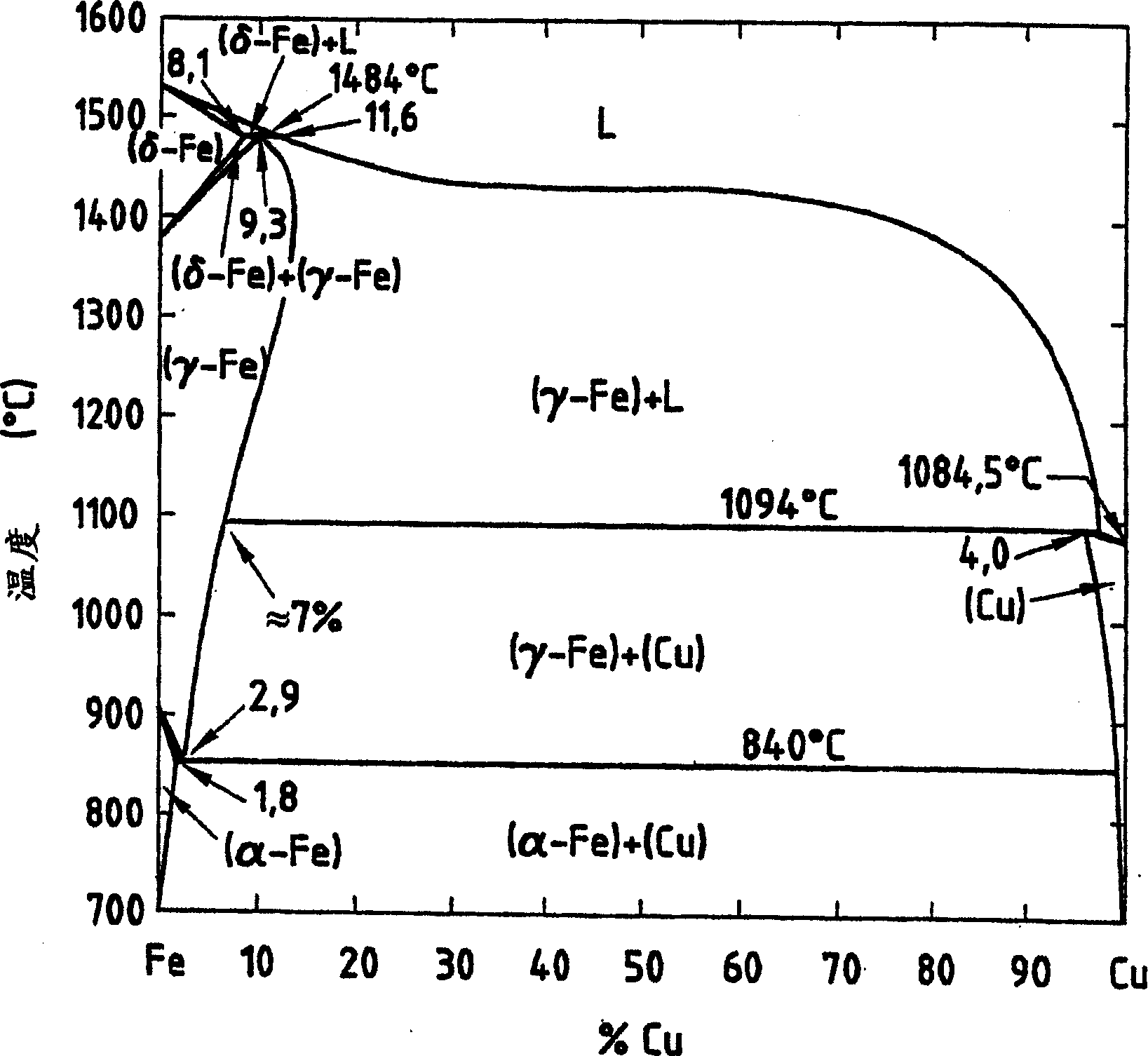

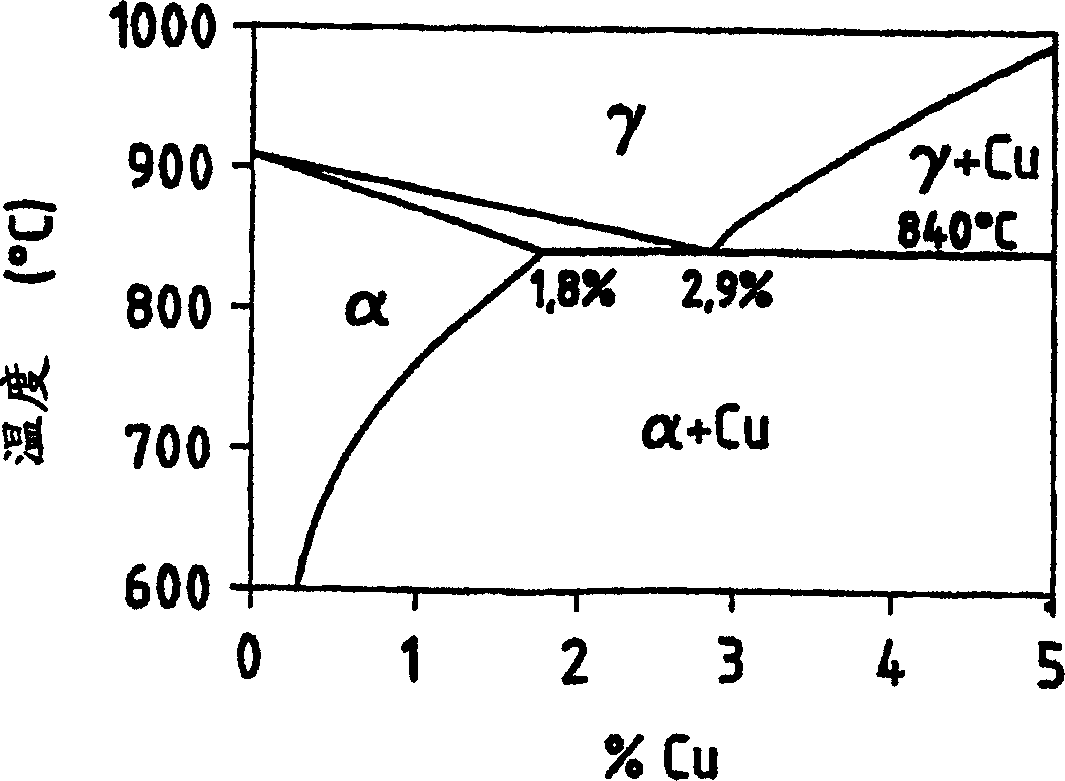

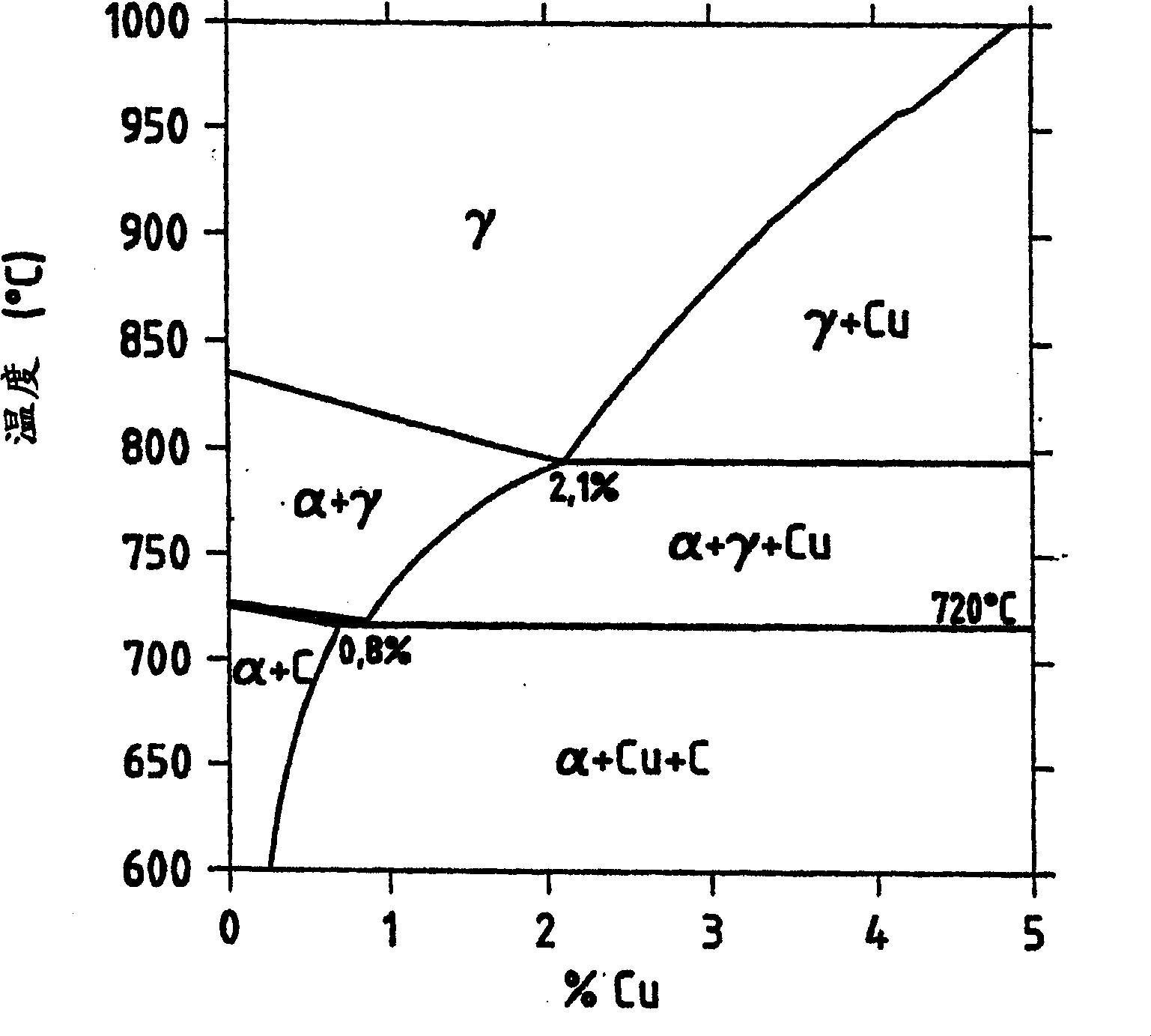

[0049] In particular, the carbon content may range from 0.0005% to 1%, depending on the intended application of the final article. The lower limit of 0.0005% practically corresponds to the smallest value possible by conventional methods of decarburizing liquid metals. The upper limit of 1% was justified via the gammagenic effect of carbon. Above 1%, carbon excessively reduces the solubility of copper in ferrite. Furthermore, above 1%, the weldability of the steel would be significantly impaired, which would render the steel unsuitable for the numerous preferred applications of the steel obtainable from the steel of the invention.

[0050] In addition, carbon causes a hardening effect and, if a large amount of titanium and / or niobium is present in the steel, leads to the precipitation of titanium carbide and / or niobium carbide used to control the textur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com