Polyurethane-imide resin, adhesive composition and adhesive composition for circuit connection

A technology of imide resin and polyurethane, applied in the direction of polyurea/polyurethane adhesive, adhesive type, conductive adhesive, etc., can solve the problems of productivity, unfavorable cost, complicated process, etc., and achieve adhesiveness Excellent, improved adhesion reliability, and excellent connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

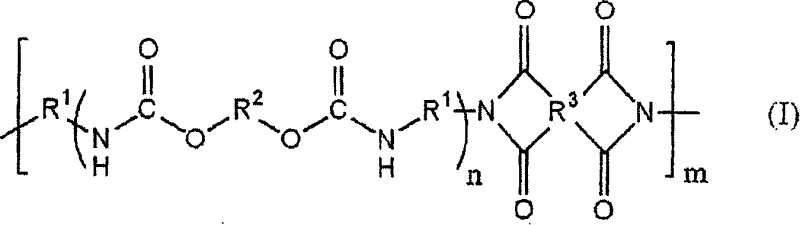

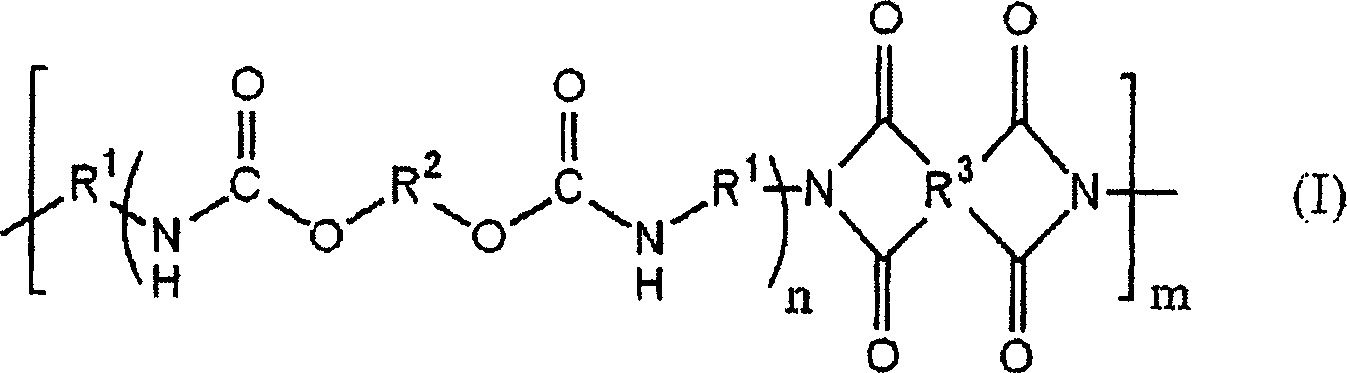

Method used

Image

Examples

Embodiment 1

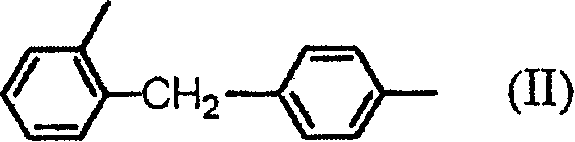

[0111] In 1-methyl-2-pyrrolidone, diphenylmethane-4,4'-diisocyanate (1.0mol), diphenylmethane-2,4'-diisocyanate ( 1.0mol) and polytetramethylene glycol (0.8mol) with an average molecular weight of 1000 were reacted for 1 hour, and 4,4'-hydroxyphthalic anhydride (1.0mol), triethylamine and 1-methyl-2 - pyrrolidone, further stirring at 100° C. for 3 hours. Further, benzyl alcohol was added, and the mixture was stirred at 100°C for 1 hour to complete the reaction. The obtained solution was put into vigorously stirred water, the precipitate was filtered, and dried in vacuum at 80° C. for 8 hours to obtain polyurethane-imide resin PUI-1. As a result of measuring the obtained polyurethane-imide resin by GPC (gel permeation chromatography), Mw=51000 and Mn=22000 in terms of polystyrene. In addition, this urethane-imide resin was soluble in methyl ethyl ketone at a solid content of 40% by weight.

[0112] The obtained polyurethane-imide resin was dissolved in methyl ethyl ketone wi...

Embodiment 2

[0114] The diol component of PUI-1 was changed to poly(hexamethylene carbonate) having an average molecular weight of 2000, and synthesized in the same manner as in Example 1 to obtain PUI-2. As a result of measurement by GPC, Mw=55000 and Mn=25000 in terms of polystyrene.

[0115] This PUI-2 was formulated in accordance with Table 1 in the same manner as in Example 1 to obtain a film-like adhesive having a thickness of the adhesive layer of 20 μm.

Embodiment 3

[0117] The glycol component of PUI-1 is changed into the polytetramethylene glycol (0.4mol) that the average molecular weight is 1000, the poly(hexamethylene carbonate) (0.4mol) that the average molecular weight is 2000, synthesizes in the same way as Example 1 , get PUI-3. As a result of measurement by GPC, Mw=55000 and Mn=25000 in terms of polystyrene. In addition, this polyurethane imide resin was soluble in methyl ethyl ketone at a solid content of 40% by weight.

[0118] This PUI-3 was formulated in accordance with Table 1 in the same manner as in Example 1 to obtain a film-like adhesive having an adhesive layer thickness of 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com