High-block degradable membrane and its manufacturing method

A degradable film, high barrier technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., to achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

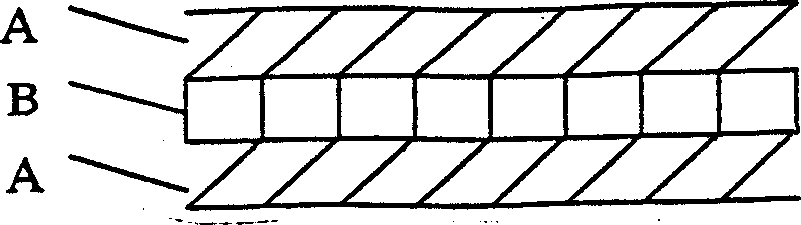

[0073] In one embodiment of the present invention, the packaging film and bag are PO / nano-PPC or nano-PVA / PO three-layer structure.

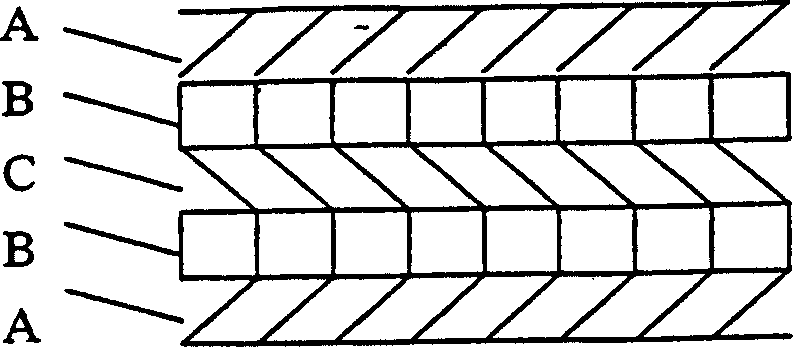

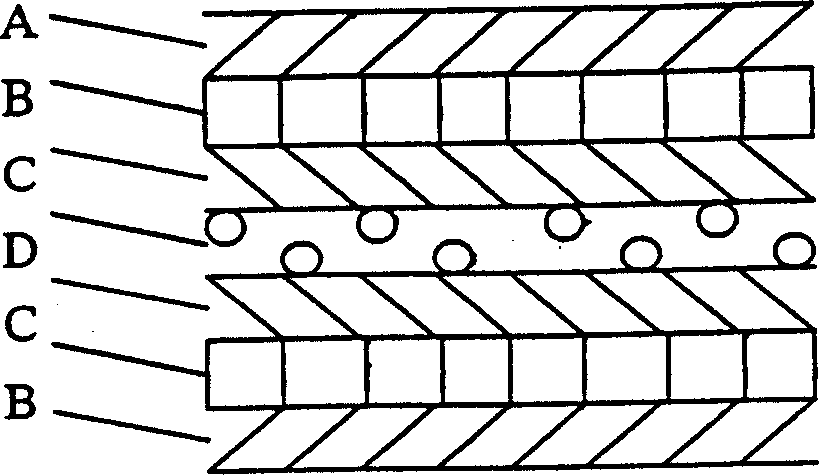

[0074] In another embodiment of the present invention, the food packaging film and bag are at least one of PO / nano-modified PPC, (PCL) or (APC) or a combination thereof / PVA / PPC, PCL or APC At least one or its combination / POD five-layer structure. The thickness of various embodiments is 5-50um / 10-100um / 5-50um5-30um / 5-30um / 10-50um / 5-30um / 5-30um.

[0075] See attached picture:

[0076] figure 1 The structure is PO / nano-PPC or nano-PVA / PO three-layer structure, wherein the A layer is PO, and the B layer is one of nano-PPC, nano-PVA or a combination thereof.

[0077] figure 2 It is at least one of PO / nano-modified PPC, (PCL) or (APC) or its combination / at least one of PVA / PPC, PCL or APC or a combination / POD five-layer structure, wherein the A layer is PO , The B layer is at least one of nano-modified PPC, (PCL) or (APC) or a combination thereo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com