Method for preparing Soft polyurethane foam with excellent ball elasticity

A soft polyurethane and foam technology, which is applied in the field of preparation of soft polyurethane foam, can solve the problem of mechanical strength such as tensile breaking strength, elongation and even tensile strength, or compressive strength reduction, improve ball resilience, and can not achieve rebound Mechanical properties and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

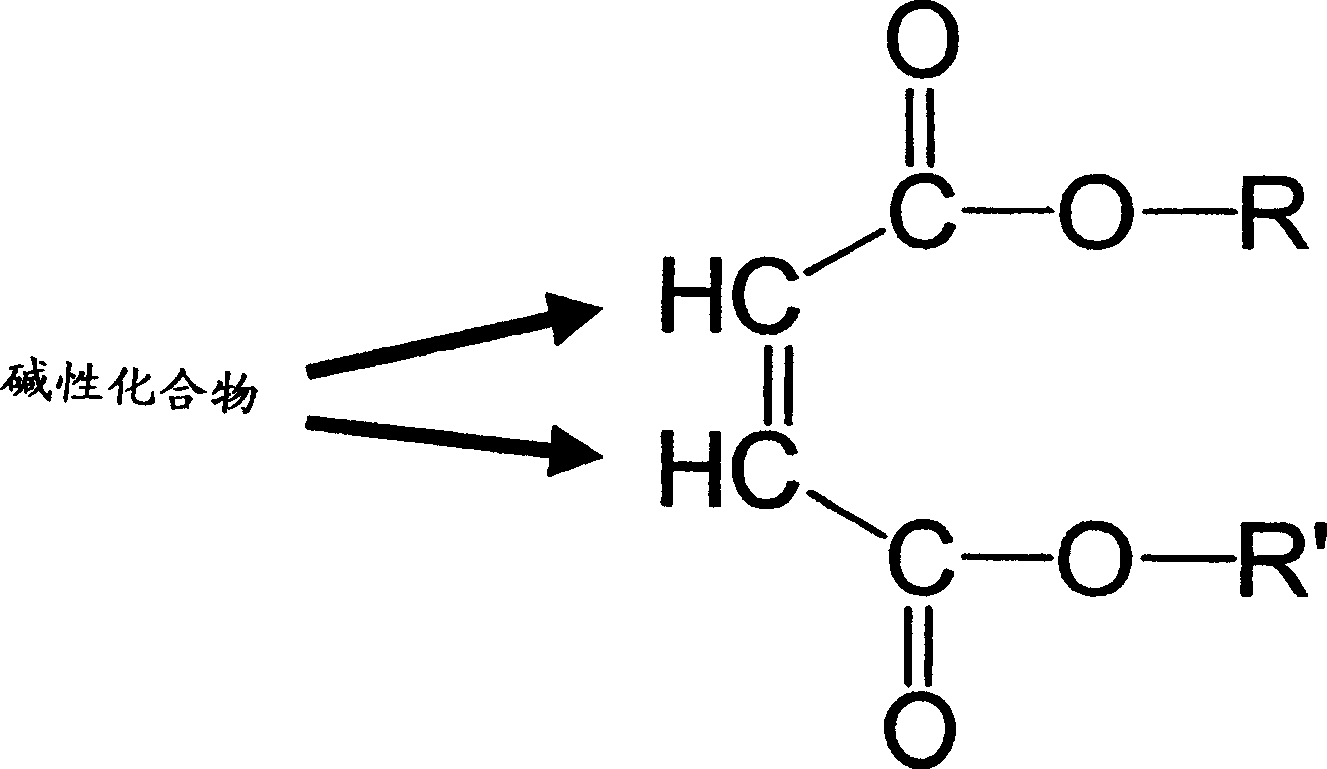

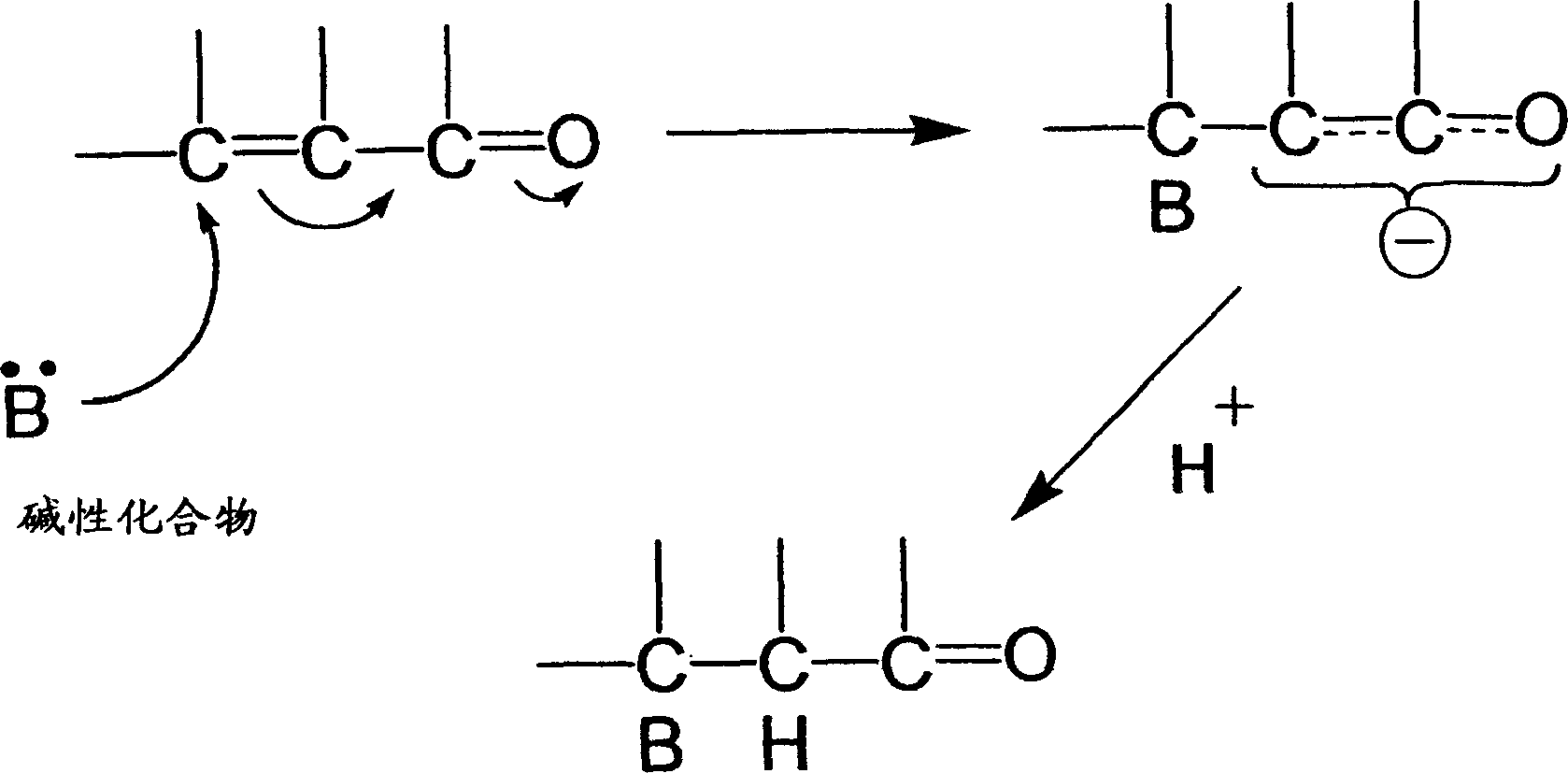

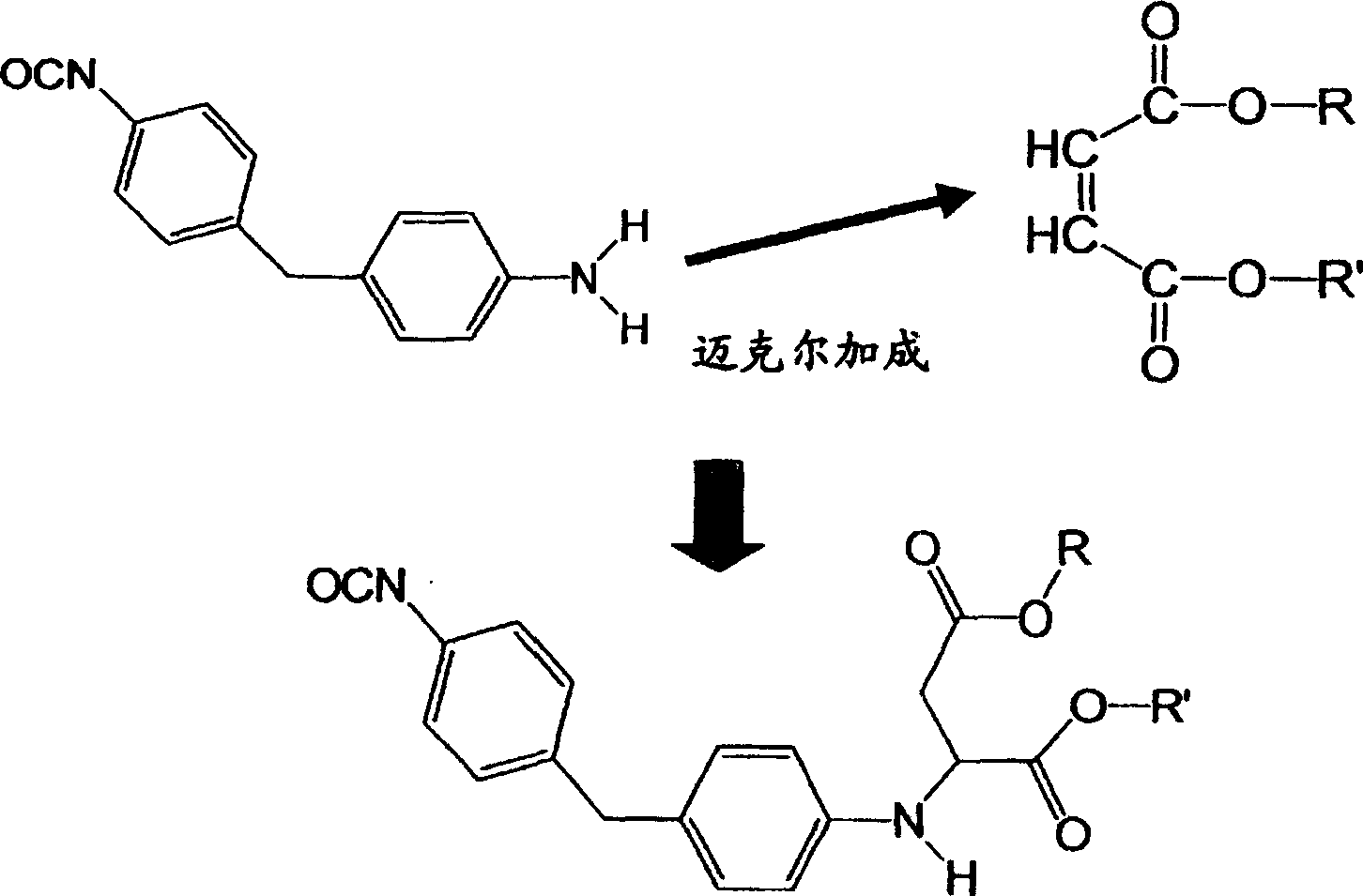

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~5

[0107] According to the compounding ratios described in Table 1 and Table 2, the polyol premix and the isocyanate component were mixed, and after they were adjusted to 25°C, they were weighed in a 2000 ml polycup (Polycap) and mixed with a hand mixer. Stir at 3000 rpm for 10 seconds. Immediately after the stirring is finished, it is poured into an acrylic box with an inner size of 250×250×250mm for foaming. After standing still for 24 hours, it was cut into a predetermined shape, and the items shown in Table 3 were measured. The measuring methods of physical properties are based on JIS K 6400.

[0108] diverse

Pre-alcohol

mixture

Judgment

Cyanic acid

ester

Ester

index

ball back

elastic

%

Appearance

density

kg / m 3

25% pressure

Shrinkage strength

N / 100cm 2

to stretch

intensity

kPa

elongate

%

crack

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com