Novel hydrophilic adhesive compositions

A composition and adhesive technology, applied in adhesives, viscous dressings, surgical adhesives, etc., can solve problems such as insufficient adhesiveness and cohesion, impossibility, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

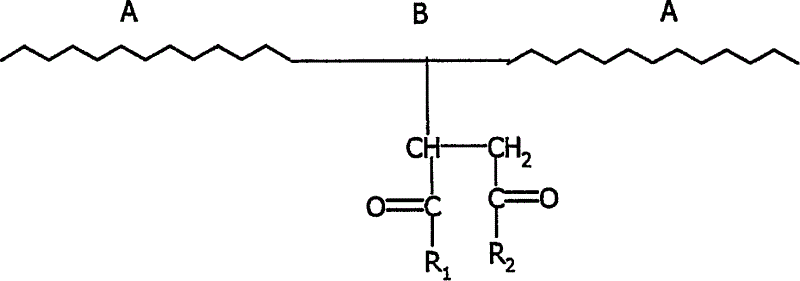

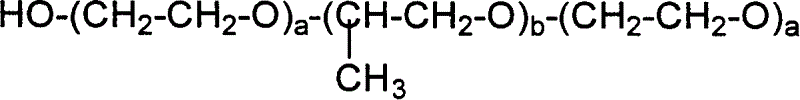

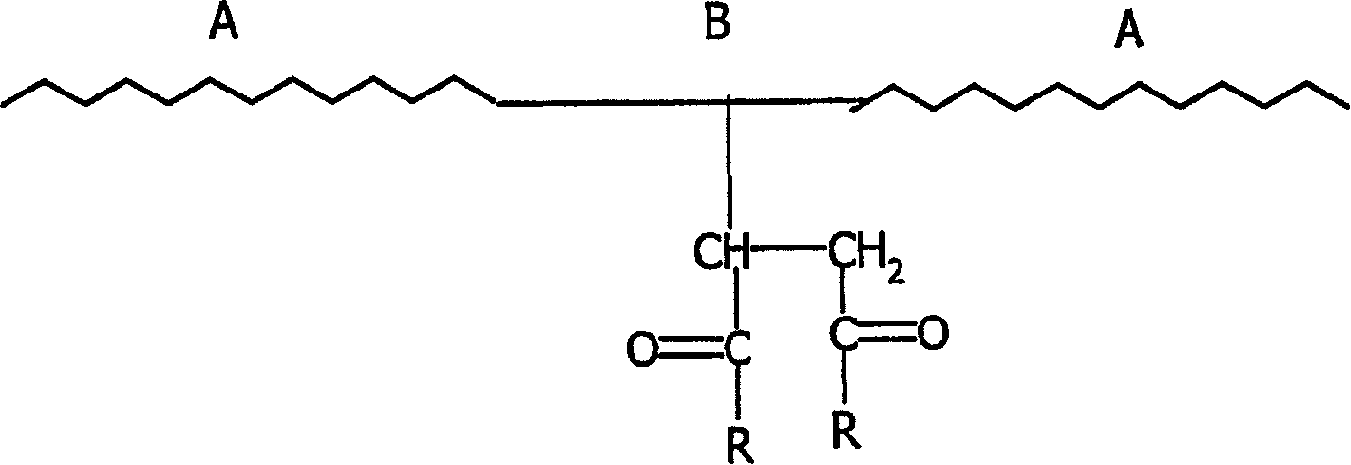

[0204] For the purpose of simplification, a synthesis example of a typical amphoteric copolymer, which is used in all the adhesive compositions given below as examples, is given first.

preparation example I

[0208] 150 ml of toluene were introduced into the reactor under nitrogen atmosphere. Add Kraton purchased from SHELL G 1901 (maleinated SEBS copolymer) 20 g. Heat with stirring at reflux (approximately 110° C.) until the maleated SEBS copolymer is completely dissolved. In addition, a solution of PEGME with a molar mass of 2000 and a trade name of polyethylene glycol monomethyl ether 2000 from Aldrich Company was prepared. 32.32 g of PEGME 2000 were dissolved in 100 ml of toluene by heating to its melting point with stirring. Still under stirring and reflux conditions, about 20 drops of sulfuric acid were added to the previously obtained maleated SEBS copolymer solution. Then, still under stirring and reflux conditions, the previously prepared PEGME 2000 in toluene solution was added. Thus, there are now 4 hydroxyl functions for each anhydride function. The resulting mixture was stirred continuously at reflux until the esterification reaction was complete, ie, about 30 t...

Embodiment 5

[0233] The airtight jacketed reactor is heated to a temperature between 90 and 100°C, constantly stirred with an agitator equipped with a deflocculation propeller, and the rotating speed is about 500 to 800rpm, and the following reactants are added continuously: 1 gram of amphoteric copolymer, 29.4 grams of water, 7.36 grams of BASF trade name Kollidon 30 polyvinylpyrrolidone polymers, 56.8 grams of TOTAL company trade name GEMSEAL 60 plasticizer (liquid mixture of saturated hydrocarbons), 0.2 grams of hydrophobic preservative (methylparaben) and 0.2 grams of hydrophilic preservative (propylparaben).

[0234] Stir continuously at 90-100°C until a homogeneous mixture is obtained.

[0235] Then, stir continuously at 90-100°C and introduce 5 grams of VECTOR DPX-565, which is a mixture of triblock copolymer (styrene-isoprene-styrene) and diblock copolymer (styrene-isoprene) commercialized by EXXON MOBIL Chemical Company. Keep stirring constantly at the same temperature un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com