Net making method using pin printing head and its equipment

A kind of equipment and needle printing head technology, which is applied to screen printing machines, rotary printing machines, printing, etc., can solve the problems of waste water from screen making, waste gas pollution of the environment, large amount of equipment maintenance, and low degree of automation, and achieve labor wages and related cost reduction, improvement of net production efficiency, improvement of quality and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

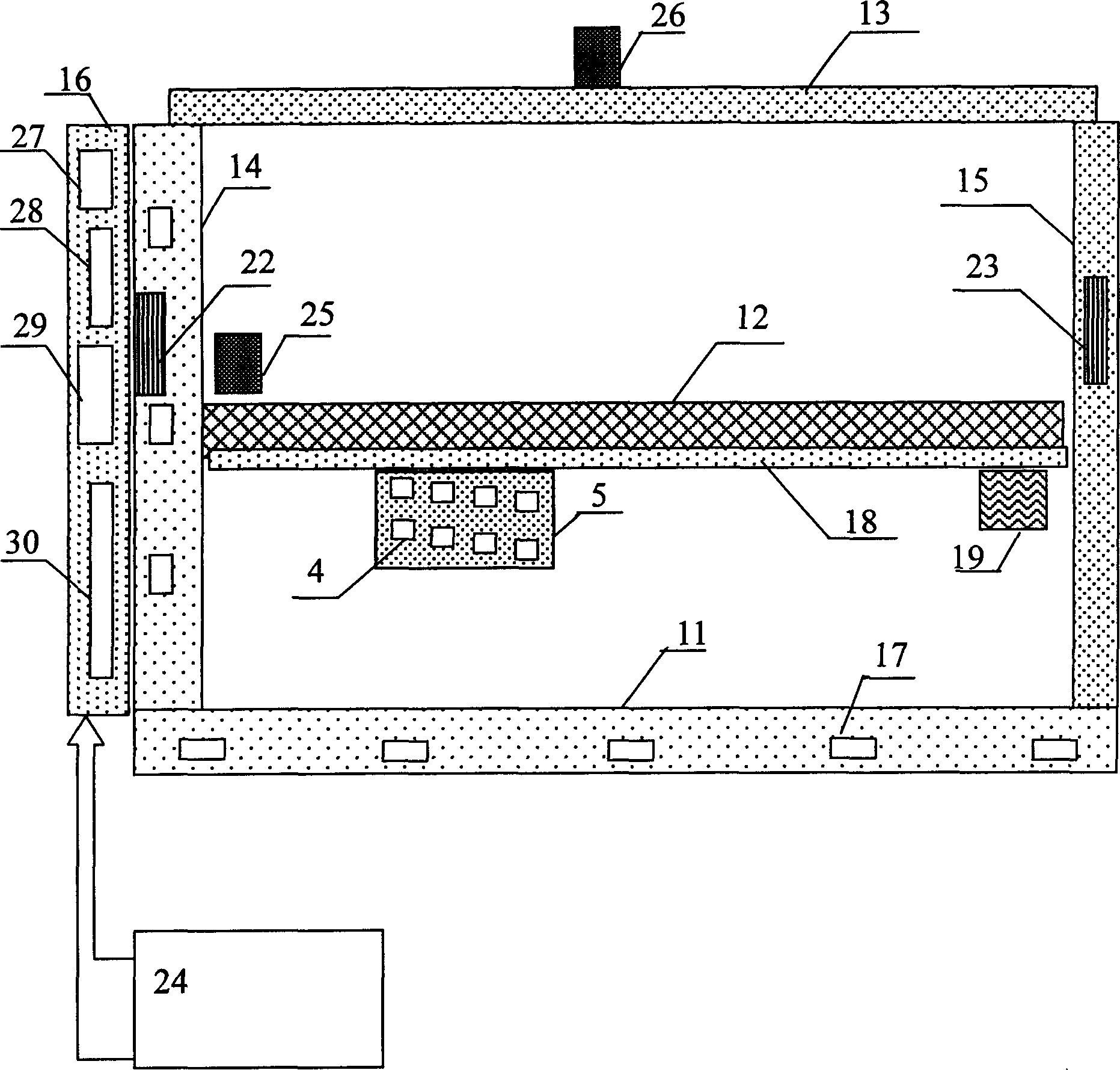

[0034] The needle punching netting method of the present invention comprises the following steps: 1. coating thermosetting powder slurry on the screen; 2. needle punching with color separation patterns; 3. heating and curing.

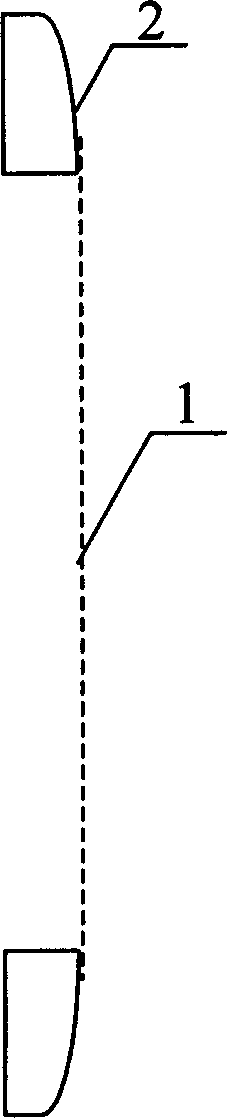

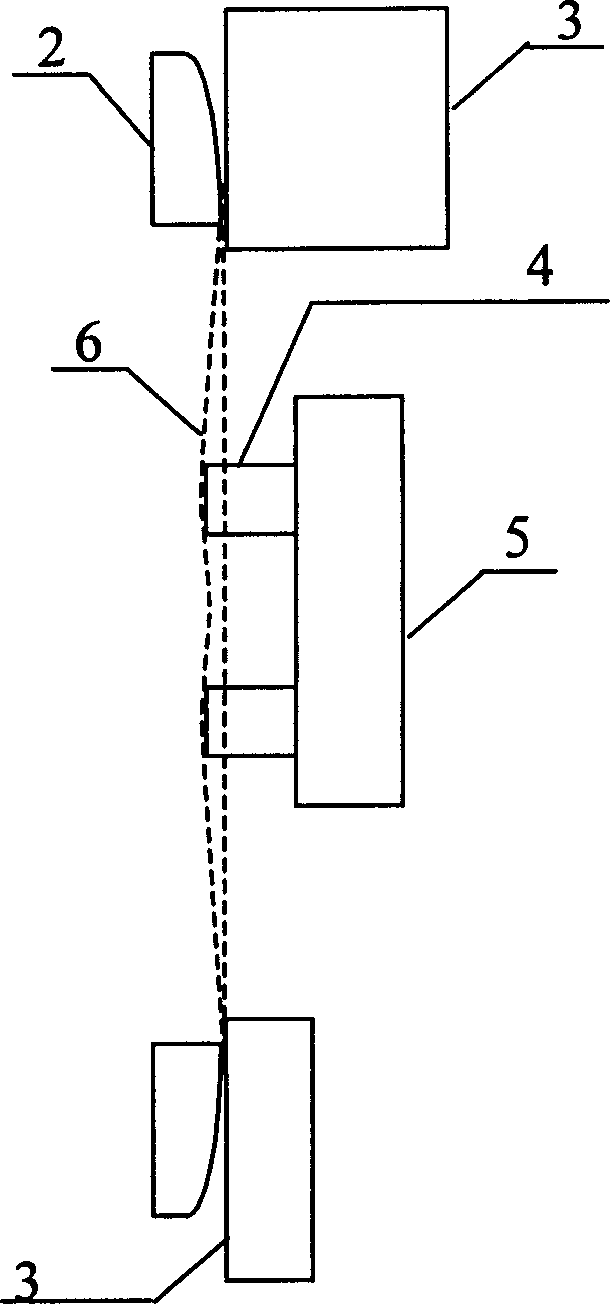

[0035] figure 2 Shows the schematic diagram of the mesh making method of the present invention, step 1 coating thermosetting powder slurry on the screen includes: tensioning the screen 1 on the flat mesh frame 2, such as figure 1 shown; then the thermosetting powder slurry is coated on the screen 1 to block the mesh, and after drying, the coating screen 6 is obtained; the thermosetting powder slurry is a mixture of thermosetting powder and glue, and the particle size of the thermosetting powder is between 0-200 μm, the thermosetting powder is hot-sol powder, the melting temperature is lower than 150° C., and the hot-melt powder is nylon hot-sol powder.

[0036]Step 2 color separation pattern injection includes: fixing the coating screen 6 on the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com