Laminated ceramic thermocouple and its preparing method

A technology of thermocouples and ceramics, applied in the direction of thermoelectric devices, circuits, thermometers using electric/magnetic elements that are directly sensitive to heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

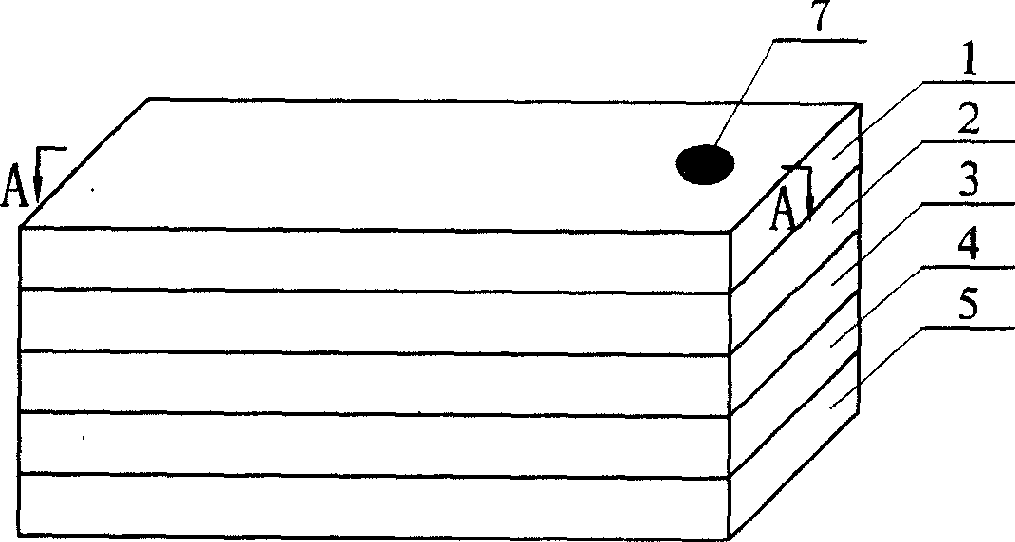

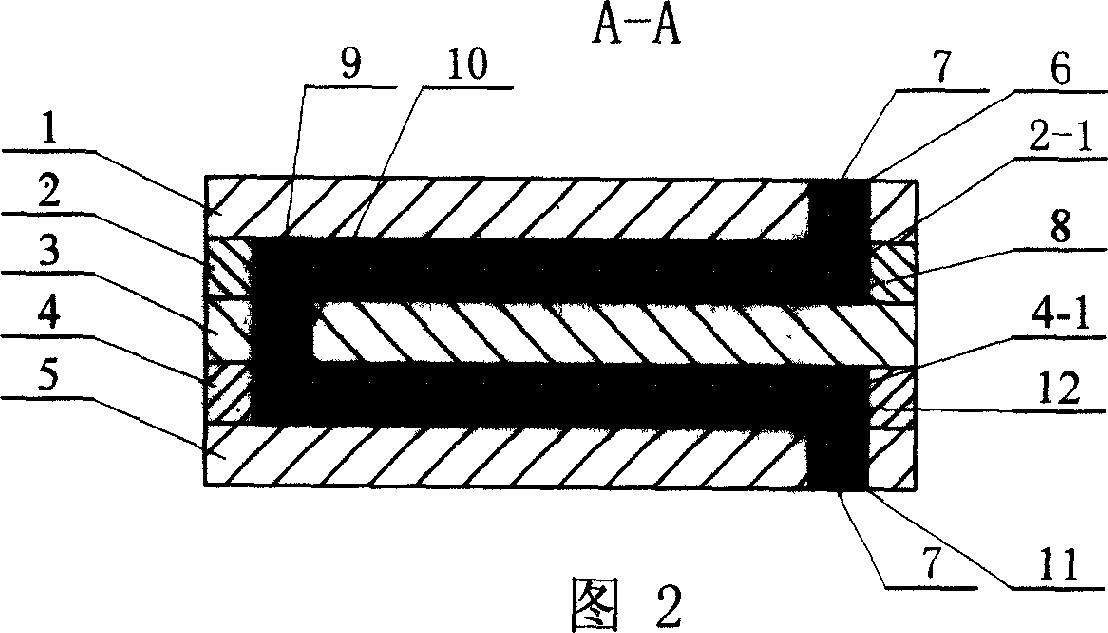

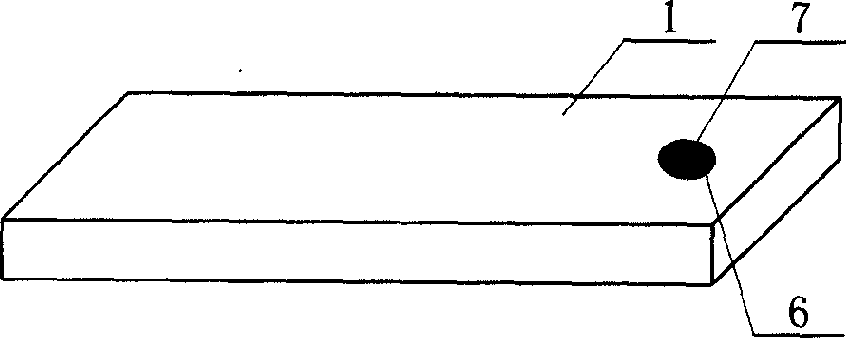

[0010] Specific implementation mode one: see Figure 1-7 , the laminated ceramic thermocouple of the present embodiment consists of an upper insulating substrate 1, a positive plate 2, a positive electrode 2-1, a middle insulating substrate 3, a negative plate 4, a negative electrode 4-1, and a lower insulating substrate 5; the upper insulating A first through hole 6 is opened between the upper end surface and the lower end surface on the right side of the substrate 1, and a conductive terminal 7 is embedded in the first through hole 6, and a third through hole 6 is opened between the upper end surface and the lower end surface on the right side of the lower insulating substrate 5. A through hole 11, a conductive terminal 7 is embedded in the third through hole 11; a first through groove 8 is opened between the upper end surface and the lower end surface of the positive plate 2, and the positive electrode 2-1 is embedded in the first through groove 8; A second through hole 10 ...

specific Embodiment approach 2

[0015] Specific embodiment two: In this embodiment, a laminated ceramic thermocouple is prepared in this way: the upper insulating substrate 1, the positive plate 2, the middle insulating substrate 3, the negative electrode plate 4, and the lower insulating substrate 5 are stacked in order from top to bottom Together, they are sintered at a sintering temperature of 1500-2500°C and a sintering pressure of 0.1-80Mpa. Since the matrix of the positive plate 2 and the negative plate 4 is the same ceramic material as the upper insulating substrate 1, the middle insulating substrate 3, and the lower insulating substrate 5, the primary problem of this embodiment is to prepare the insulating ceramic material matrix used by the thermocouple device, Utilize this base material to manufacture the ceramic blank strip with specially prefabricated through grooves 8 for mounting positive electrode 2-1, negative electrode 4-1 and through holes 6 for mounting conductive terminals 7 and conductive...

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 2 is that during the heating process of the billet, a reinforcing phase is formed due to the chemical reaction between the insulating matrix components and the sintering environment. In this embodiment, the material system is mainly The nitrogen oxide compound phase AlON, the compound is the prefabricated sample in the oxidizing atmosphere at 1500 ~ 1900 ° C pressureless sintering conditions according to AlN-Al 2 o 3 -Si 2 ON 2 The result of the reaction in the system. In order to increase the strength of oxynitride, β-silicon nitride with high static flexural strength is used, depending on the Si used 3 N 4 :AlN:Al 2 o 3 : Si 2 ON 2 The composition includes 0.5 to 15 vol.% silicon nitride and oxynitride phases in volume ratios ranging from 1:2:14:4 to 2:1:11:6. Thermocouples made of this material can be used up to 1400°C under oxidizing and inert conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com