Device and method for quick gas supply when diesel engine accelerating

A diesel engine, fast technology, applied in the direction of charging system, electrical control, mechanical equipment, etc., can solve the problems of diesel quality difficult to meet, high manufacturing cost, technical difficulty, etc., to improve transient emission quality, facilitate modification, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

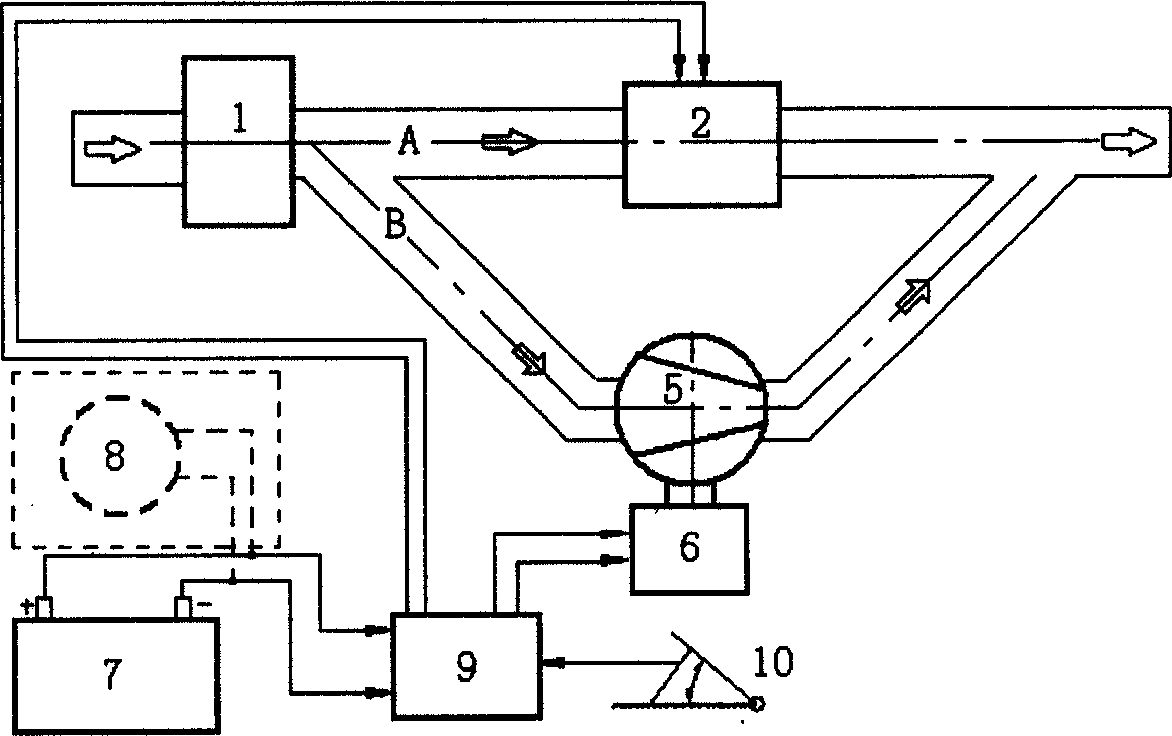

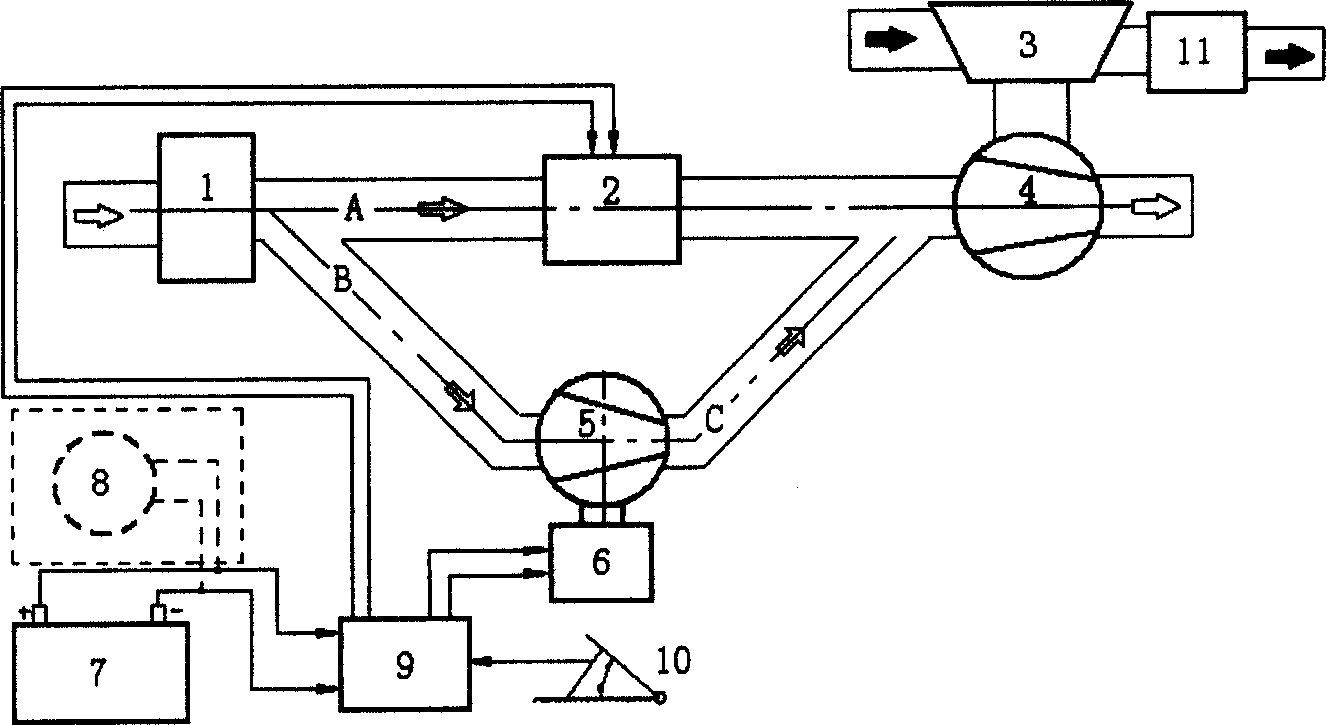

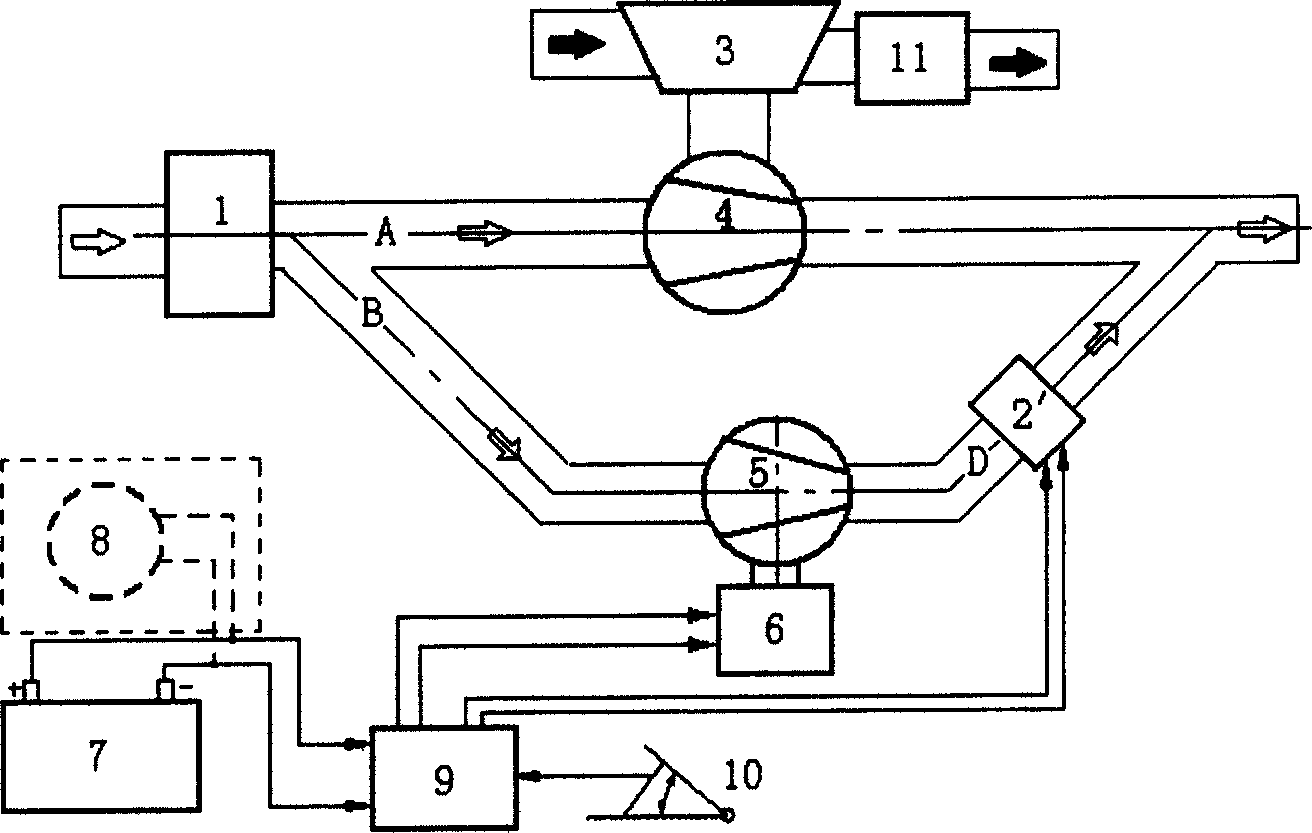

[0027] 1. Carry out such as on the direct injection supercharged engine figure 2 Intake manifold arrangement shown, i.e. the electric compressor is installed between the original diesel engine turbocharger and the air filter. The electric compressor is driven by a GWD1500 high-speed brushless motor with a speed of up to 24000r / min. Under a certain constant torque, the accelerator actuator is driven by the stepper motor at a constant speed to pull the accelerator line to move in the direction of refueling, so that the speed increases, and changing the stepping interval of the stepper motor can change the speed change rate, and install an acceleration sensor on the accelerator pedal Detect acceleration. The electronic control unit is mainly composed of MS-51 single-chip microcomputer, which can collect signals such as engine speed, torque, acceleration, etc., and judge the working condition of the engine to send the start signal of the electric compressor. The working time of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com