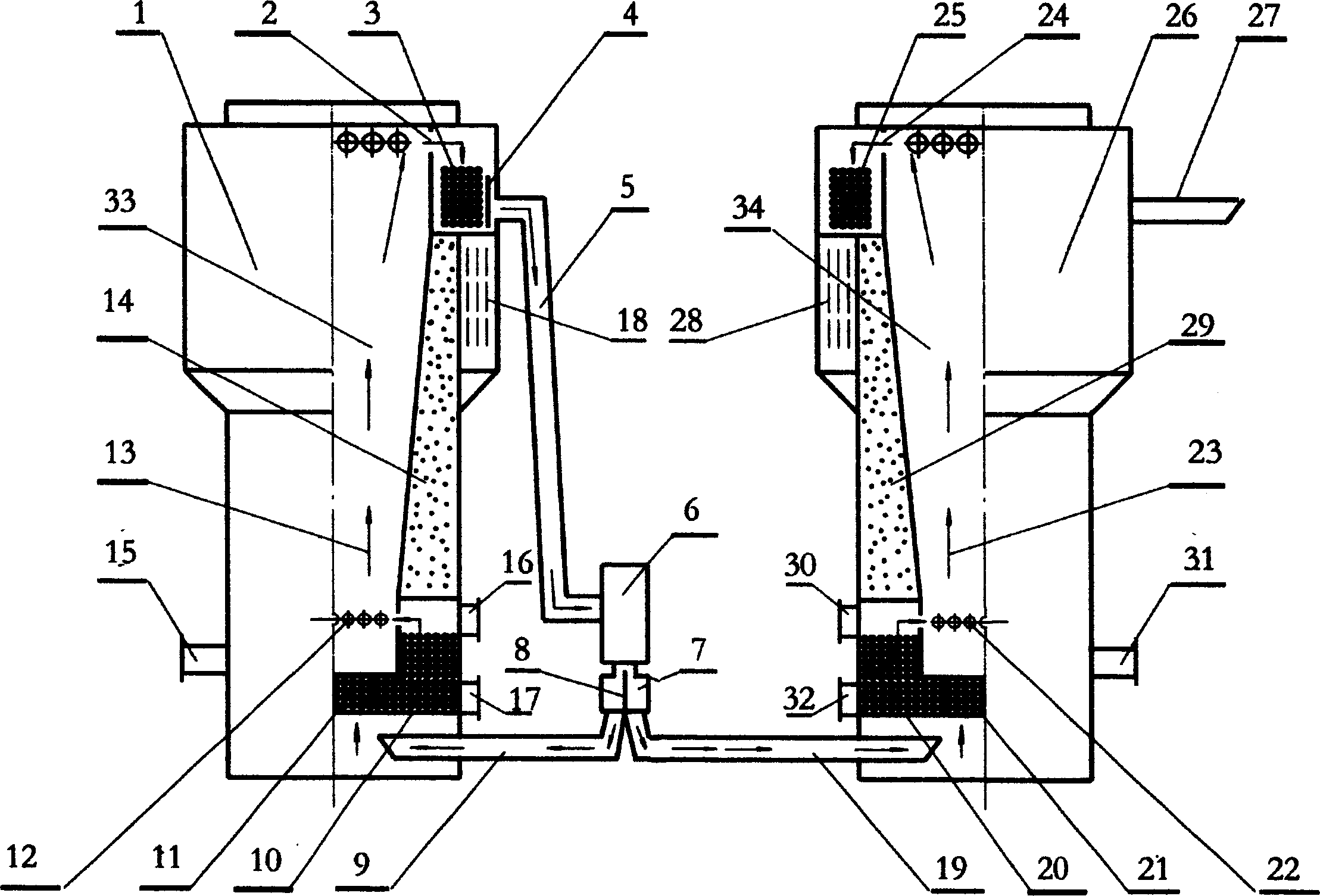

Combined biomass vaporization furnace and thermal cracking device thereof

A gasifier and thermal cracking technology, which is applied in the field of gasifiers, can solve the problems of difficult distribution of dolomite activated carbon, increased gasification cost, inconvenient use, etc., and achieves the effects of low production cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention will be further described:

[0020] The invention adopts two biomass gasification furnaces to jointly participate in gas production, and provides pure gas flow for users with a composite thermal cracking device.

[0021] The two gasifiers 1 and 26 are ignited after the biomass fuel is installed, and the blower 6 is used to supply air to the two biomass gasifiers 1 and 26 respectively. After the first gasifier 1 generates gas flow, the gas flow first From the numerous air outlet holes 2 on the upper part of the gasifier, it flows into the granular catalyst 3 on the upper part to participate in the first thermal cracking, the gas flow enters the pipeline 5 from the stainless steel wire mesh 4 at the gas outlet, and the gas flow flows from the air inlet of the blower , enter the blower 6, respectively pass through the air volume regulator 7 of the blower, and use the adjustment plate 8 to adjust the air volume, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com