A genetically engineered bacteria, its constructing method and use thereof

A technology of genetically engineered bacteria and construction methods, applied in the field of genetically engineered bacteria, can solve problems such as increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

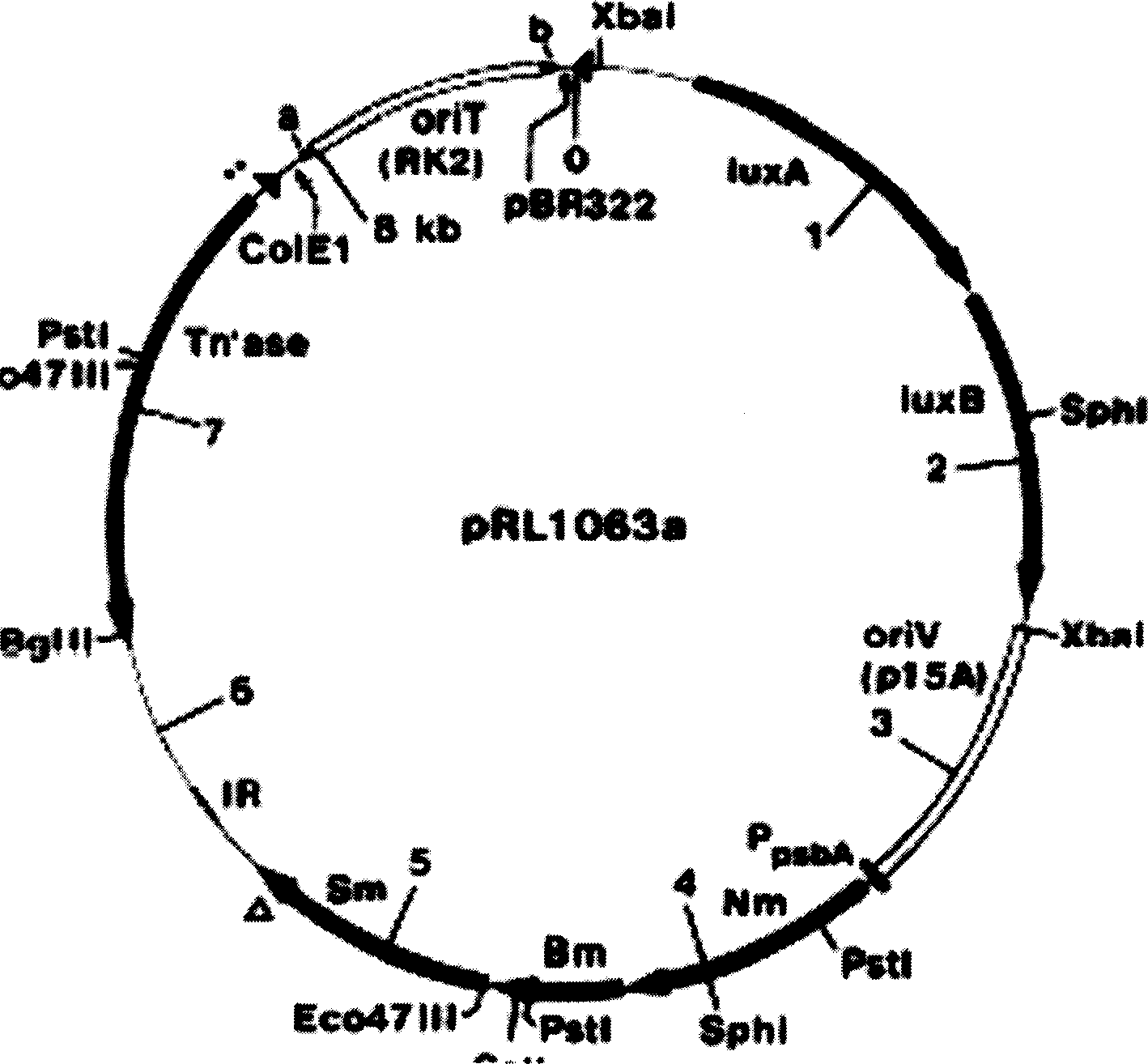

[0064] The plasmid vector pRL1063a and the starting strain were respectively cultured on LB medium containing 10 μg / L kanamycin; the plasmid vector pRL1063a in the logarithmic phase of growth was mixed with the starting strain at a volume ratio of 1:1.2, and mixed at a temperature of 30 ℃, act on a shaker at 200rpm / min for 30 minutes, centrifuge at 12000r / min for 10min, wash twice with normal saline, discard the supernatant, and inoculate the bacterial pellet on LB solid medium, and inoculate at 30℃ Incubate for 24 hours. The obtained culture was a mixture of the plasmid vector pRL1063a, the starting strain, and the mutant strain inserted into the transposon S17-1.

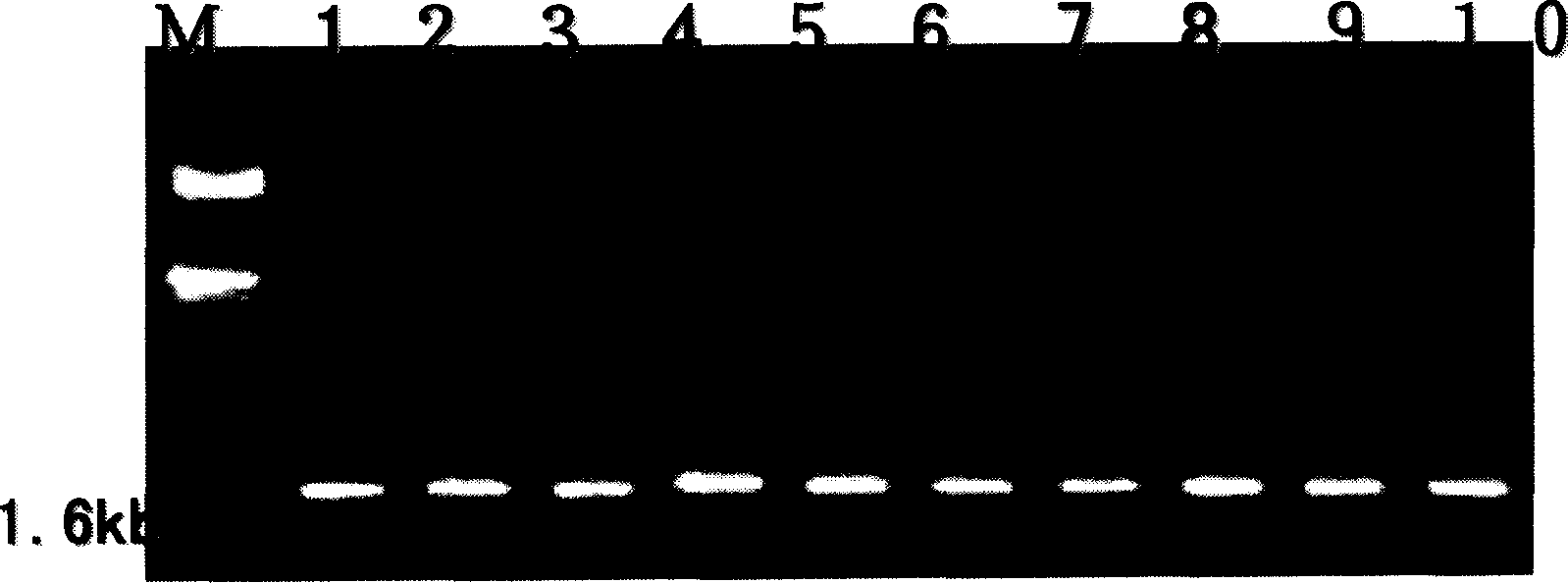

[0065] Scrape off the cultured bacterial pellet with a toothpick, suspend it with MG liquid medium, and spread it on the plate of MG solid medium (the concentration of kanamycin is 10 μg / L, and the concentration of streptomycin is 30 μg / L). Cultivate at a temperature of 30°C for 7-8 days, transfer the grown singl...

Embodiment 2

[0069] The plasmid vector pRL1063a and the starting strain were respectively cultured on LB medium containing 5 μg / L kanamycin; the plasmid vector pRL1063a in the logarithmic phase of growth was mixed with the starting strain at a volume ratio of 1:1, and mixed at a temperature of 26 ℃, act on a shaker at 150rpm / min for 20 minutes, centrifuge at 20000r / min for 5min, wash once with normal saline, discard the supernatant, and inoculate the bacterial pellet on LB solid medium. Incubate for 12 hours. The obtained culture was a mixture of the plasmid vector pRL1063a, the starting strain, and the mutant strain inserted into the transposon S17-1.

[0070] Scrape off the cultured bacterial pellet with a toothpick, suspend it with MG liquid medium, and spread it on the plate of MG solid medium (the concentration of kanamycin is 5 μg / L, and the concentration of streptomycin is 20 μg / L). Cultivate at 26°C for 5 days, transfer the grown single colony to a new MG solid medium (the concent...

Embodiment 3

[0074] The plasmid vector pRL1063a and the starting strain were cultured on LB medium containing 15 μg / L kanamycin respectively; the plasmid vector pRL1063a in the logarithmic phase of growth was mixed with the starting strain at a volume ratio of 1:2, and mixed at a temperature of 32 ℃, 300rpm / min shaker for 40 minutes, centrifuged at 10000r / min for 15min, discarded the supernatant, inoculated the bacterial pellet on LB solid medium, and cultivated at 32℃ for 48 hours. The obtained culture was a mixture of the plasmid vector pRL1063a, the starting strain, and the mutant strain inserted into the transposon S17-1.

[0075] Scrape off the cultivated bacterial precipitate with a toothpick, suspend MG with liquid medium, and spread it on the plate of MG solid medium (concentration of kanamycin is 15 μg / L, concentration of streptomycin is 40 μg / L). Cultivate at 32°C for 10 days, and transfer the grown single colony to a new MG solid medium (with a concentration of 15 μg / L kanamycin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com