Use of zinc-magnesium-aluminium ternary hydrotalcite as nitrogen oxide adsorbent

A zinc-magnesium-aluminum ternary and nitrogen oxide technology, applied in other chemical processes, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

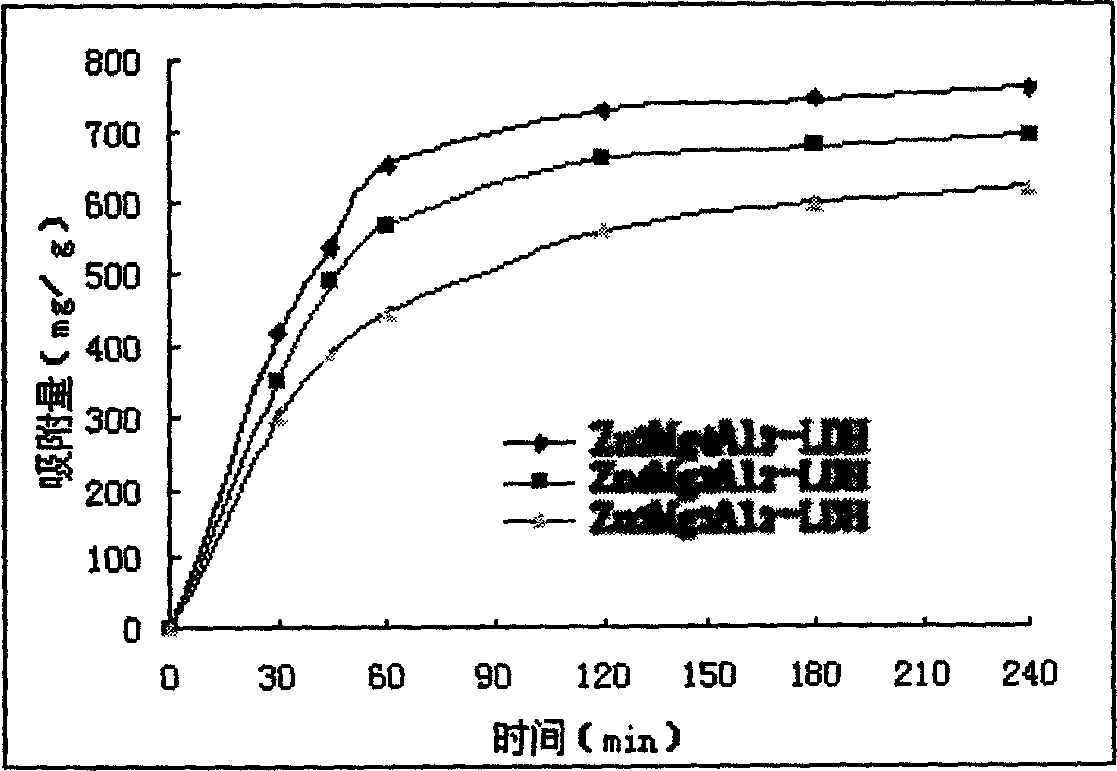

Embodiment 1

[0015] By Zn(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is made into 100mL solution A according to molar ratio Zn / Mg / Al=2:4:2, and wherein aluminum ion content is 0.4mol / L; NaOH, Na 2 CO 3 Prepare 100mL solution B, wherein the concentration of NaOH is 3.2mol / L, Na 2 CO 3 The concentration is 0.8mol / L. Add solution A and solution B dropwise to 200ml of deionized water at the same time, keep the dropping rate of 1 drop / second, keep the temperature at 40°C, stir vigorously, keep the pH value at about 9, continue to stir for a while after the dropwise addition, at 65 ℃ for 14 hours, centrifuged, beaten and washed until neutral, and dried at 70 ℃ for 15 hours to obtain a ternary hydrotalcite sample.

Embodiment 2

[0017] By Zn(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is made into 100mL solution A according to Zn / Mg / Al=4:2:2, wherein the aluminum ion content is 0.4mol / L; NaOH, Na 2 CO 3 Prepare 100mL solution B, wherein the concentration of NaOH is 3.2mol / L, Na 2 CO 3 The concentration is 0.8mol / L. Add solution A and solution B dropwise to 200ml of deionized water at the same time, keep the dropping rate of 1 drop / second, keep the temperature at 40°C, stir vigorously, keep the pH value at about 9, continue to stir for a while after the dropwise addition, at 65 ℃ for 14 hours, centrifuged, beaten and washed until neutral, and dried at 70 ℃ for 15 hours to obtain a ternary hydrotalcite sample.

Embodiment 3

[0019] By Zn(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is prepared into 100mL solution A according to the molar ratio Zn / Mg / Al=3:3:2, wherein the aluminum ion content is 0.4mol / L; NaOH, Na 2 CO 3 Prepare 100mL solution B, wherein the concentration of NaOH is 3.2mol / L, Na 2 CO 3 The concentration is 0.8mol / L. Add solution A and solution B dropwise to 200ml of deionized water at the same time, keep the dropping rate of 1 drop / second, keep the temperature at 40°C, stir vigorously, keep the pH value at about 9, continue to stir for a while after the dropwise addition, at 65 ℃ for 14 hours, centrifuged, beaten and washed until neutral, and dried at 70 ℃ for 15 hours to obtain a ternary hydrotalcite sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com