Preparation method of bacterial cellulose/polymerized cyclodextrin composite material

A technology of bacterial cellulose and composite materials, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as limiting the ability to remove pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Add β-CD (4.34g, 3.82mmol) and 50ml of anhydrous pyridine to a three-necked flask, stir for 1 hour, and cool to 0°C in an ice-water bath. Then TCL (10.86g, 53.56mmol) dissolved in 20ml of anhydrous DMF was added dropwise to the pyridine solution. Subsequently, the reaction was stirred at 70°C for 4 hours. After cooling, 100ml of water was slowly added to the suspension. The filtered product was repeatedly washed with excess water and acetone, and finally the product was dried in a vacuum oven at 100°C for 24 hours to obtain a white solid, which is a polymerized cyclodextrin product.

[0029] Step 2. Take the polymerized cyclodextrin (3.0g, 0.5mmol) and sodium hydride (NaH) (0.3g, 12.5mmol) of step 1 and add them to 100ml of DMF solution. Stir at 25°C for 30min to activate the polymerized cyclodextrin material . Then the product is rotary evaporated to separate the solvent and the product. The obtained white solid is the activated sodium salt of polymeric cyclodex...

Embodiment 2

[0034] Step 1. Add β-CD (4.34g, 3.82mmol) and 50ml of anhydrous pyridine to a three-necked flask, stir for 1 hour, and cool to 0°C in an ice-water bath. Then TCL (6.51g, 32.13mmol) dissolved in 20ml of anhydrous DMF was added dropwise to the pyridine solution. Subsequently, the reaction was stirred at 70°C for 4 hours. After cooling, 100ml of water was slowly added to the suspension. The filtered product was repeatedly washed with excess water and acetone, and finally the product was dried in a vacuum oven at 100°C for 24 hours to obtain a white solid, which is a polymerized cyclodextrin product.

[0035] The subsequent steps are the same as the last three steps in Example 1, and are named BC-CD-2.

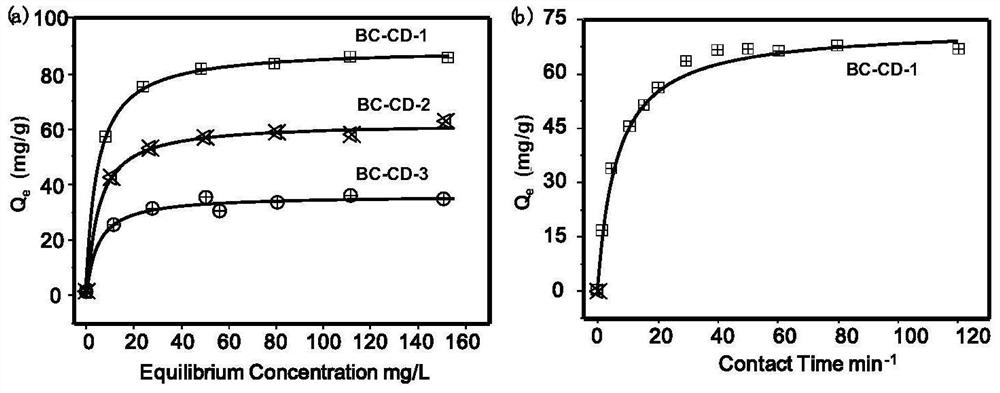

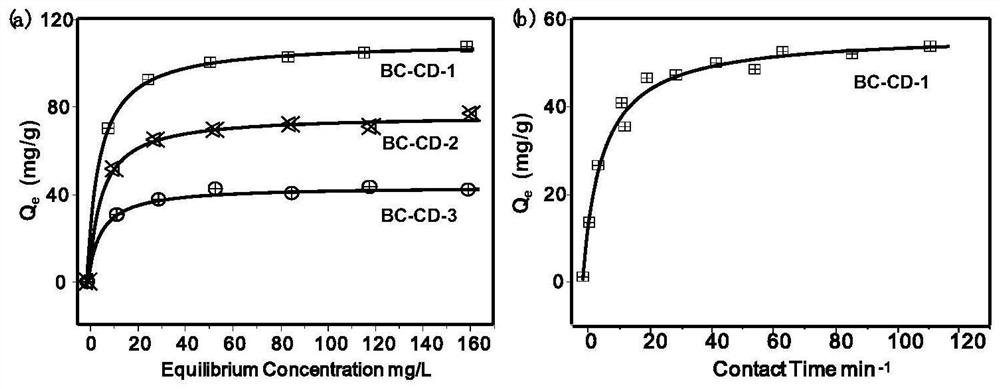

[0036] by figure 2 It can be seen that the adsorption capacity of BC-CD-2 material for phenol, aniline and bisphenol A can reach 58.6mg / g, 71.5mg / g and 40.5mg / g respectively. At the same time, it can be seen that the material has faster adsorption kinetics.

[0037] Table 1 Bacterial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com