Ministructure gas sensor array chip and its preparing method

A technology of gas sensor and array chip, which is applied in the field of gas sensor, can solve the problems of high power consumption of metal oxide sensor and hinder the popularization and application of gas sensor, and achieve good high temperature resistance, improved stability, and simplified processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

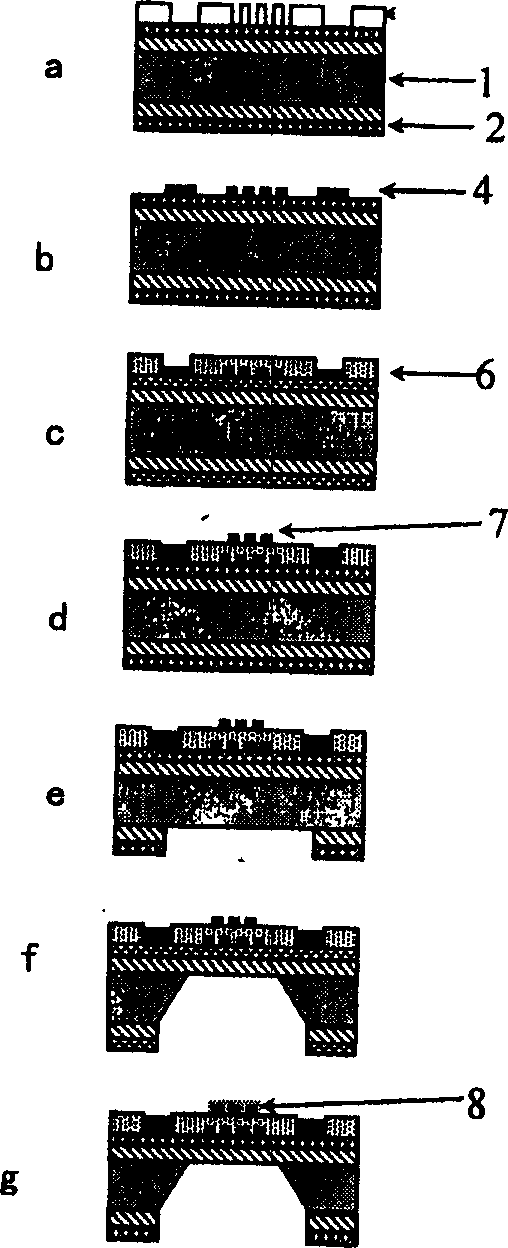

[0042] The concrete implementation method of the present invention is described in conjunction with accompanying drawing:

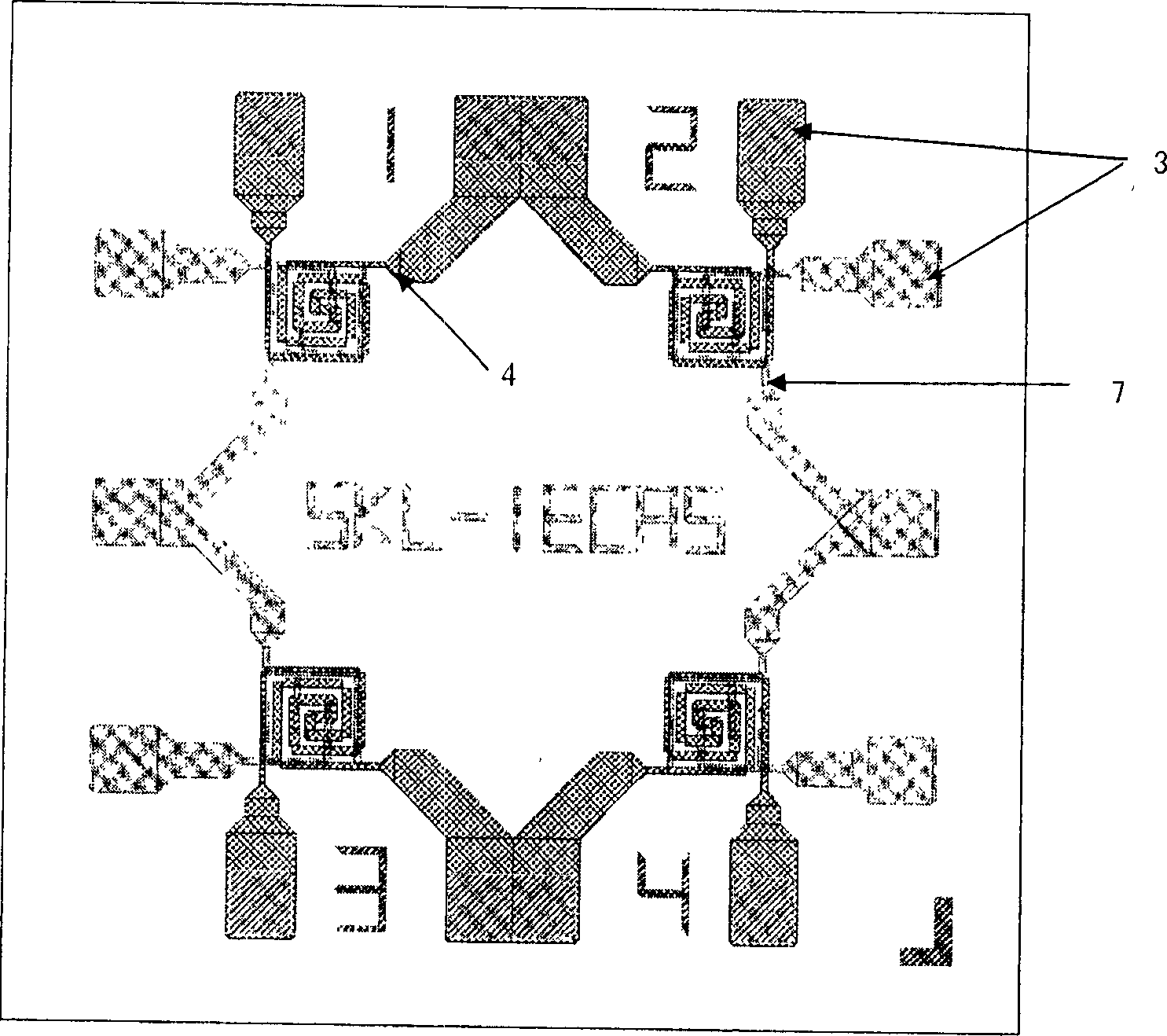

[0043] figure 1 It is a schematic diagram of the diaphragm structure of one of the units of the present invention. In the figure, 4 is a heating electrode, 7 is a measuring electrode, and 3 is a pressure welding block. Each unit of the present invention has independent heating electrode 4, is convenient to adjust the working temperature of each unit of the present invention; The current density of the electrodes is greater than that of the electrodes in the central area, and the corresponding heat generation is also relatively large, which improves the temperature uniformity of the working areas of each unit (the area with the gas-sensitive film).

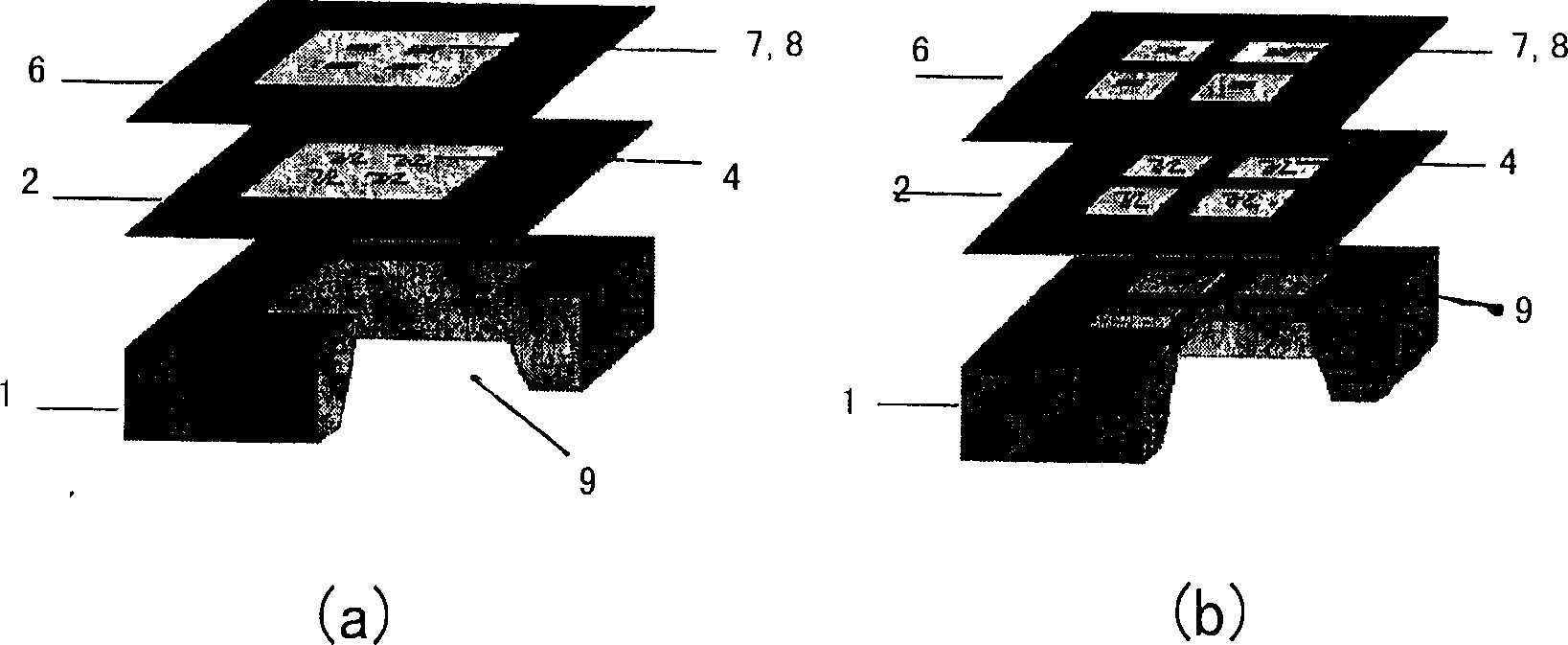

[0044] figure 2 It is a structural schematic diagram of two specific embodiments of the microstructure gas sensor array of the present invention. Among them, (a) is a single-diaphragm structure, and (b) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com