Coated conditioners for use in foods and pharmaceuticals

A conditioner and coating technology, which is applied in the forming of food, food ingredients as anti-caking agent, food ingredients as encapsulant, etc., can solve the problems of wet powder and poor flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

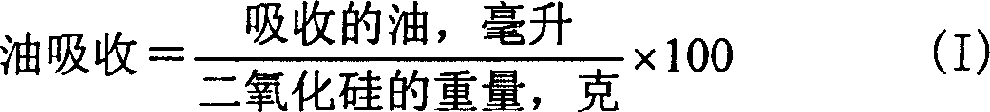

[0026] In Examples 1-8, a coating conditioner consisting of a mixture of stearic acid compound and inorganic particles was prepared according to the invention. The median particle size and oil absorption values for the inorganic particles are given in Table A below (methods for determining particle size and oil absorption values are discussed below).

[0027]In this process, first, a certain amount of inorganic particles such as silica, calcium carbonate or kaolin (as shown in Table I below) was added to a mixing bowl and the mixing bowl was connected to a Kitchen Aid Heavy Duty K5SS type mixer. To control the temperature of the mixing bowl contents, a heat jacket is added around it to heat the mixing bowl to increase the temperature of the mixing bowl contents. The temperature of the mixing bowl contents was measured by a thermocouple in contact with the mixing bowl contents, and the temperature was electronically regulated by a solid-state temperature controller connecte...

Embodiment 26-29

[0042] In Examples 26-29, a coating conditioner consisting of a mixture of mineral oil and precipitated silica was prepared according to the invention. First, 100 grams of precipitated silica (shown in Table III below) was added to a mixing bowl attached to a laboratory grade Hobart mixer. With the mixer turned on at low speed, 4.0% or 10.0% mineral oil was added and allowed to mix with the silica for 10 minutes at ambient temperature (as shown in Table III below).

[0043] Example number

Inorganic substances

mineral oil increase

26

Zeofree 80

4%

27

Zeofree 80

10%

28

Zeothix 265

4%

29

Zeothix 265

10%

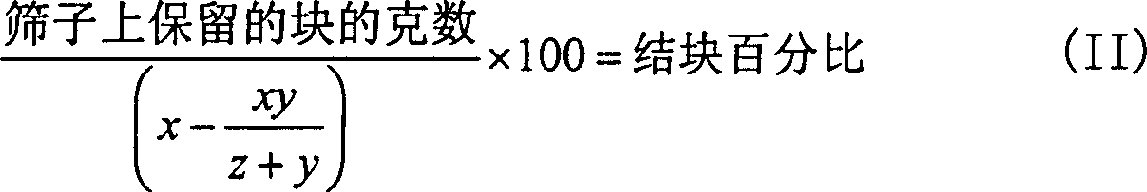

[0044] The potential of a powder to form a wet cake can be assessed using the wet cake test. A baseline correlation between moisture and unconditioned drug or food powder caking was determined prior to actual testing of the conditioned powder in the moisture cake itself (ie, drug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com