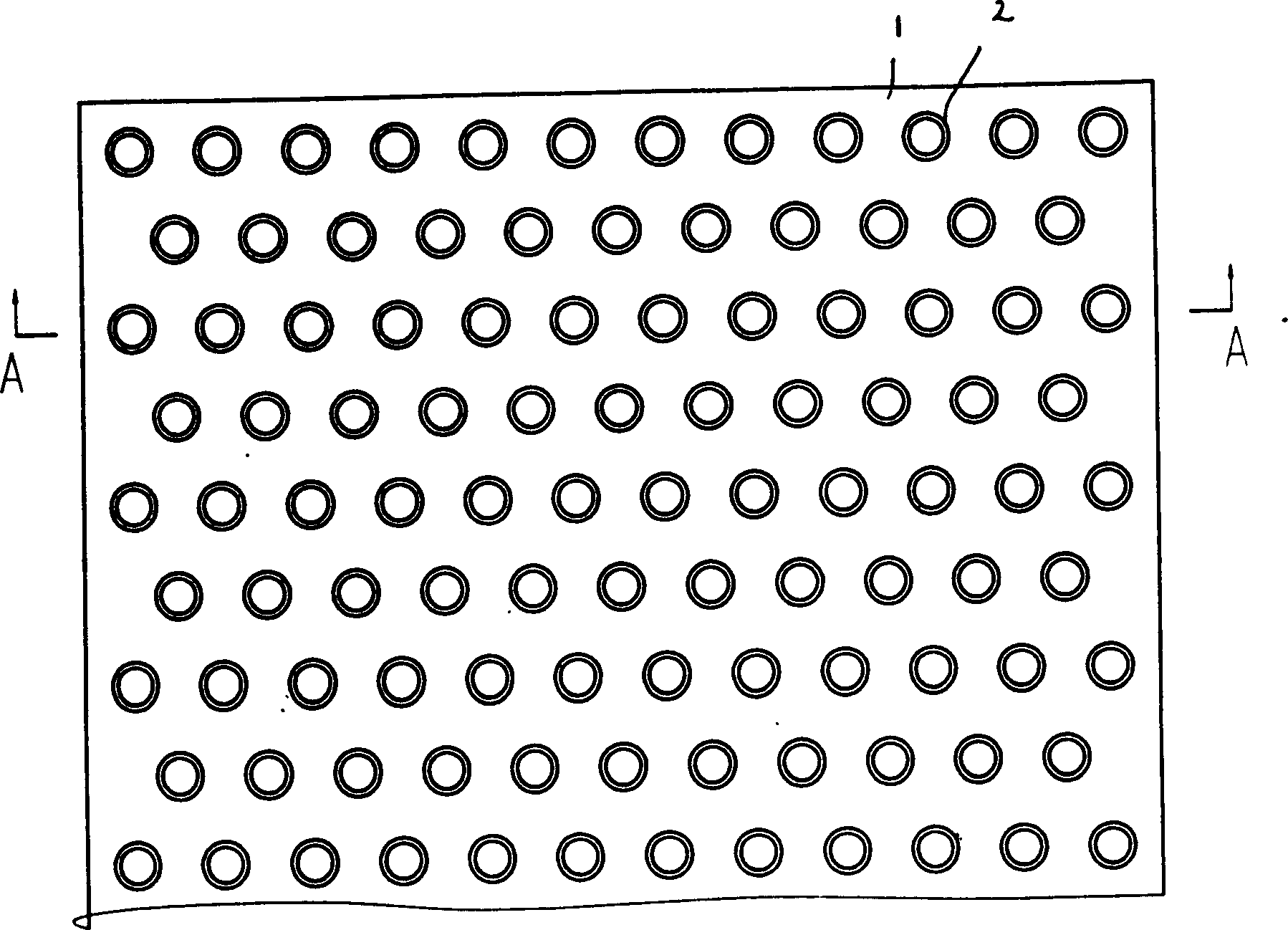

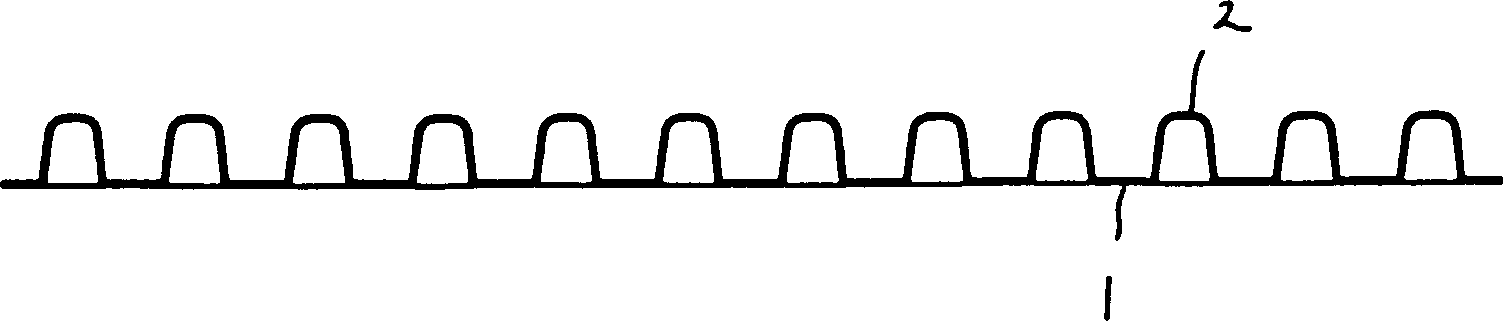

High density polyethylene drainage protection board and its preparation method

A technology of high-density polyethylene and drainage protection board, which is applied in the field of drainage protection materials and waterproofing, and can solve problems such as damage and leakage of the waterproofing system, and achieve the effects of saving building space, simple installation process, and high-efficiency strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Step 1, 85kg high-density polyethylene, 10kg low-density polyethylene, 0.5kg polyethylene wax processing aid, 1.5kg carbon black masterbatch, 1kg antioxidant thiodipropionate octadecyl fat and 2kg organotin stabilizer Di-n-butyltin silicate in February is placed in a high-low speed mixer and mixed evenly to make a mixture.

[0053] Step 2. Put the mixture obtained in Step 1 into a twin-screw extruder and extrude it.

[0054] Step 3: Place the extruded material obtained in Step 2 on a pelletizer to pelletize.

[0055] Step 4, putting the granules obtained in Step 3 into a single-screw extruder for extrusion.

[0056] Step 5, filtering the extruded material obtained in step 4 through a filter.

[0057]Step 6: Put the filter material solution obtained in Step 5 into a wide-width mold to shape it into a high-density polyethylene geomembrane.

[0058] Step 7. Place the high-density polyethylene geomembrane obtained in step 6 in a cooling box to cool, and then press and se...

Embodiment 2

[0076] 90kg high-density polyethylene, 5kg low-density polyethylene, 0.5kg polyethylene wax processing aid, 1.5kg carbon black masterbatch, 1kg antioxidant adenosine triphosphate and 2kg organotin stabilizer oxytrialkyltin They are all placed in a high-low speed mixer and mixed evenly to make a mixture. All the other are with embodiment 1.

Embodiment 3

[0078] With 88kg high-density polyethylene, 8kg low-density polyethylene, 0.3kg polyethylene wax processing aid, 1.2kg carbon black masterbatch, 0.5kg antioxidant thiodipropionate stearyl and adenosine triphosphate mixture and 2kg The organotin stabilizer di-n-butyltin silicate is placed in a high-low speed mixer and mixed evenly to make a mixture. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com