Transistor measuring instrument

A measuring instrument and transistor technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., and can solve the problems of large volume, high cost, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

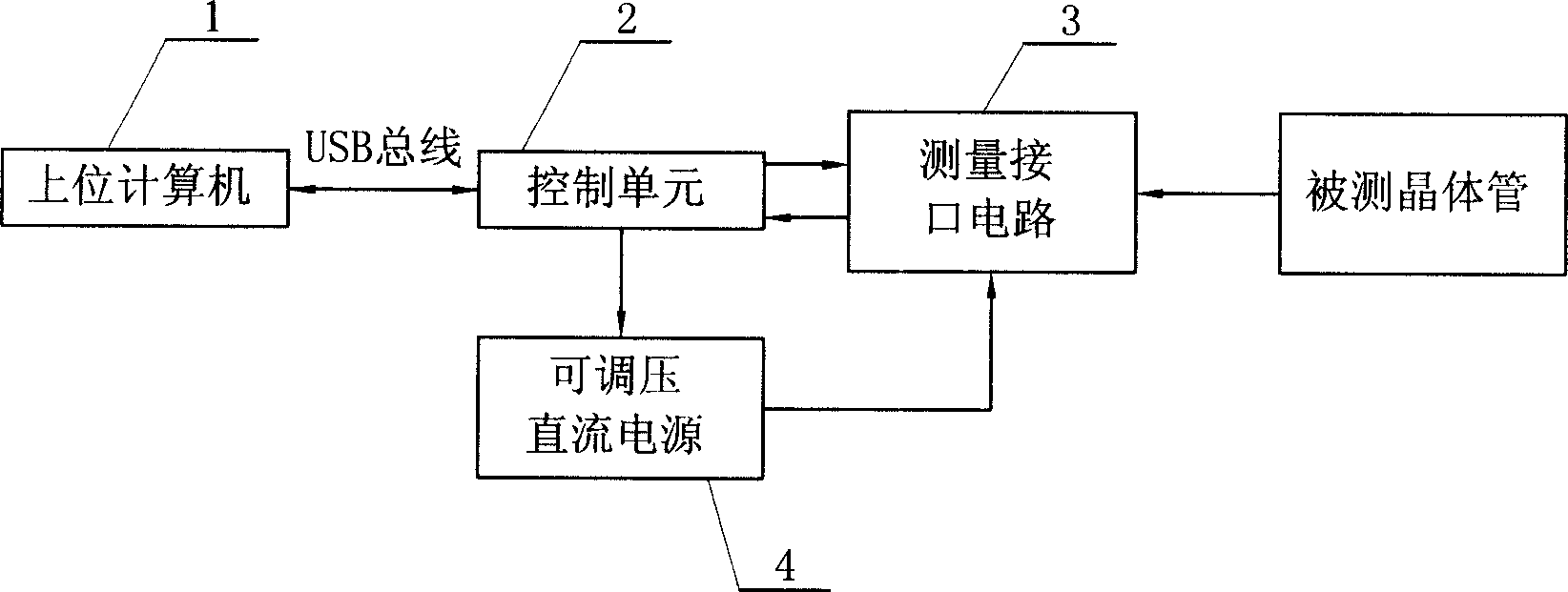

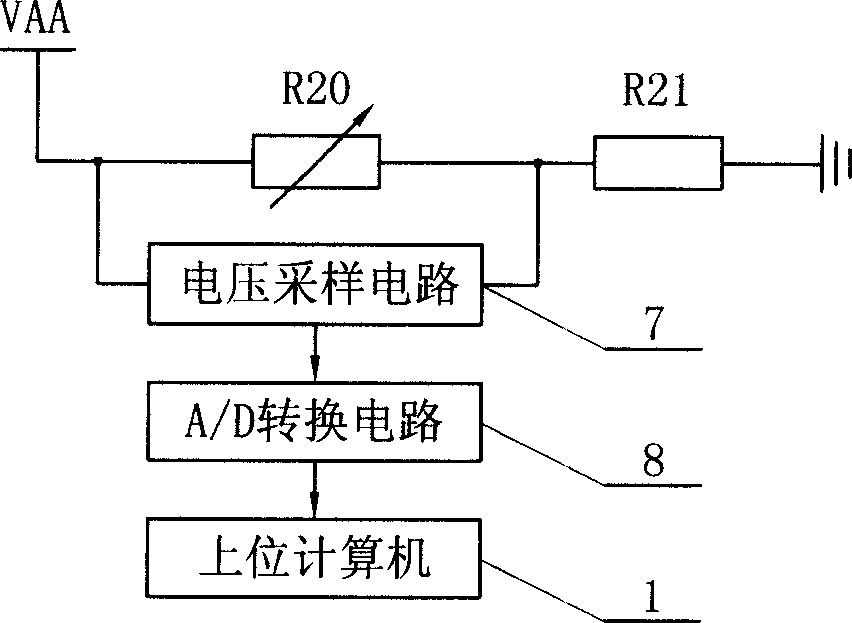

[0005] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment is composed of a host computer 1, a control unit 2, a measurement interface circuit 3, and an adjustable DC power supply 4. The communication port of the host computer 1 is connected to the communication port of the control unit 2 through a USB bus, and an output of the control unit 2 connected to the controlled end of the adjustable voltage DC power supply 4, the other output end of the control unit 2 is connected to an input end of the measurement interface circuit 3, the output end of the measurement interface circuit 3 is connected to the input end of the control unit 2, and the adjustable voltage DC The output terminal of the power supply 4 is connected to the power supply terminal of the measurement interface circuit 3 .

specific Embodiment approach 2

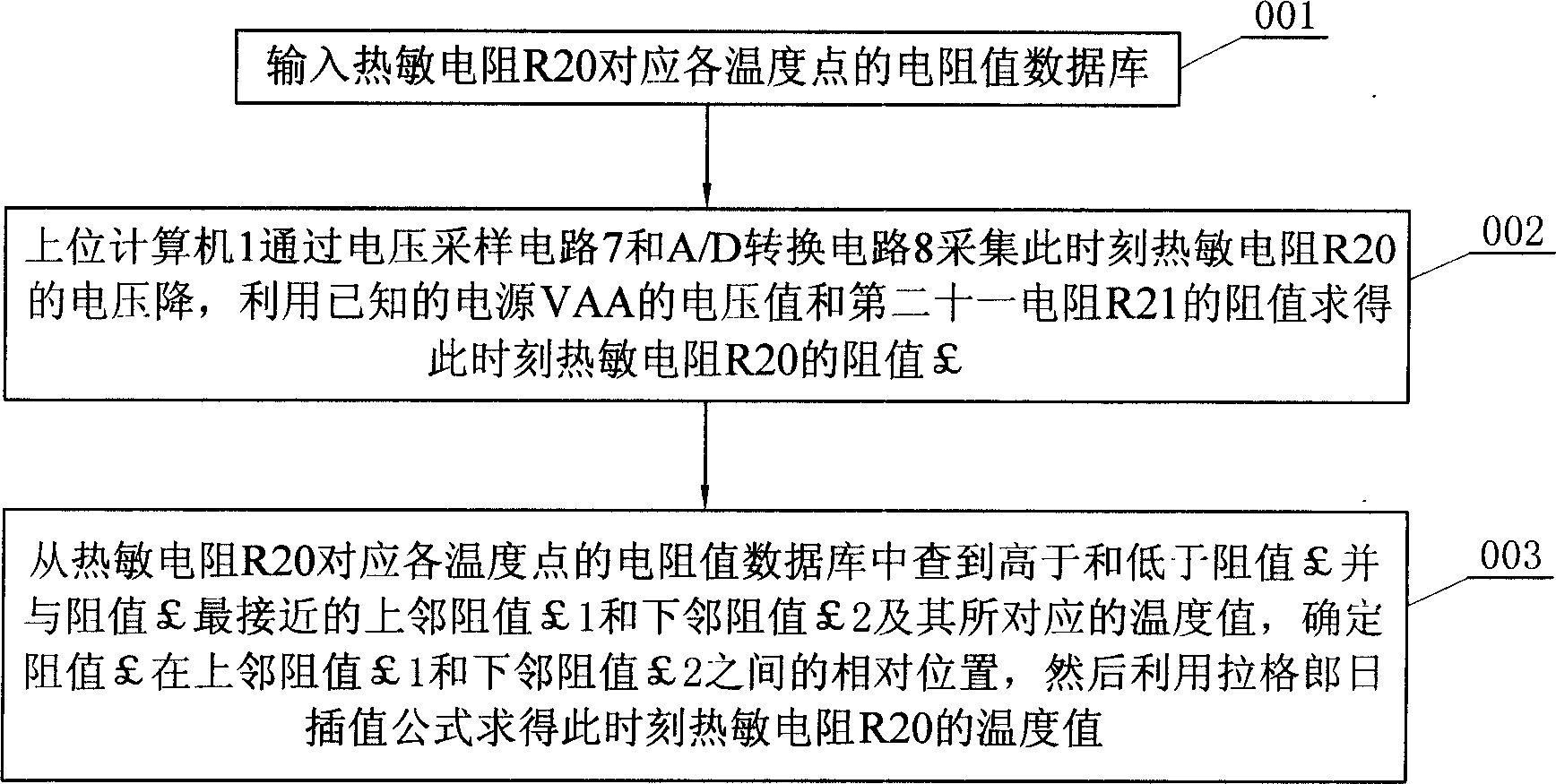

[0006] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is: the control unit 2 selects the single-chip microcomputer chip U1, the model of the single-chip microcomputer chip U1 is PIC16C765, the pin 23 and pin 24 of the single-chip microcomputer chip U1 are connected to the host computer 1 through the USB bus, and the measurement interface circuit 3 is composed of The twenty-third resistor R23, the twenty-fourth resistor R24, the twenty-fifth resistor R25, the first relay J1, the second relay J2, the third relay J3, the second diode N2, the third diode N3, The fourth diode N4 and slot J6 are formed, one end of the twenty-third resistor R23 is connected to the pin 19 of the single-chip microcomputer chip U1, and the other end of the twenty-third resistor R23 is connected to the pin 2 of the single-chip microcomputer chip U1 and the pin 1 of the No. 1 rela...

specific Embodiment approach 3

[0008] Specific implementation mode three: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and the second embodiment is that it also includes a warning circuit 6, the warning circuit 6 is composed of a third resistor R3, a field effect transistor M11 and a light emitting diode N1, and one end of the third resistor R3 is connected to the fifth resistor R5. One end, the other end of the third resistor R3 is connected to the drain of the field effect transistor M11, the source of the field effect transistor M11 is grounded, the gate of the field effect transistor M11 is connected to the cathode of the light-emitting diode N1, and the anode of the light-emitting diode N1 is connected to the single-chip microcomputer chip U1 29 feet. Other components and connections are the same as those in Embodiment 2. When testing parameters such as the amplification factor, reverse breakdown voltage, and reverse leakag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com