Techniques for fabricating a resistor on a flexible base material

A technology for resistors and flexible substrates, applied in the direction of resistors, thin film resistors, and printed resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

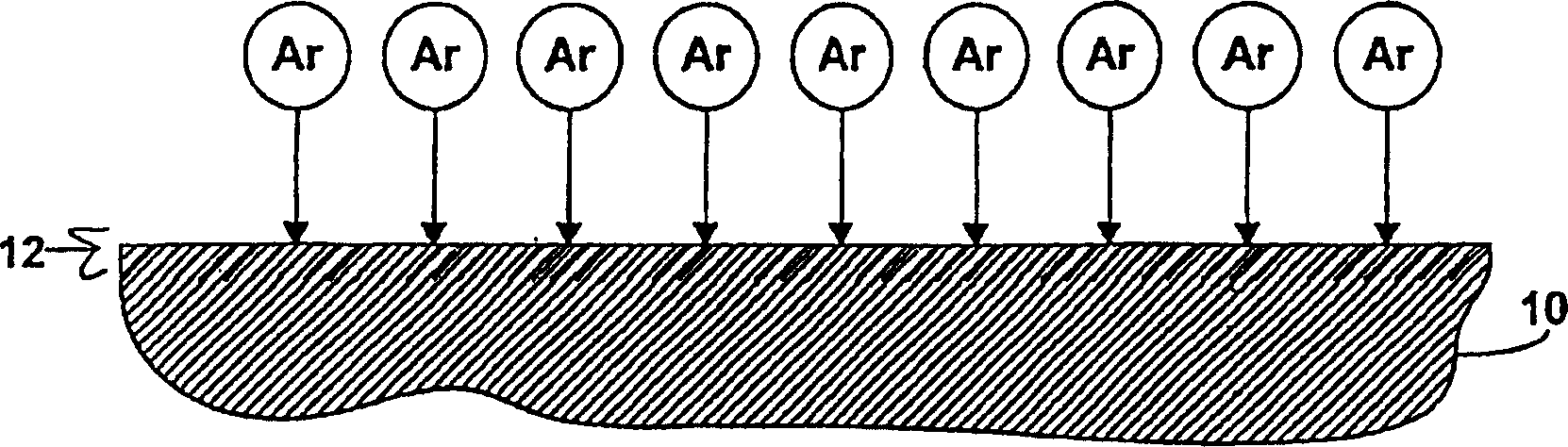

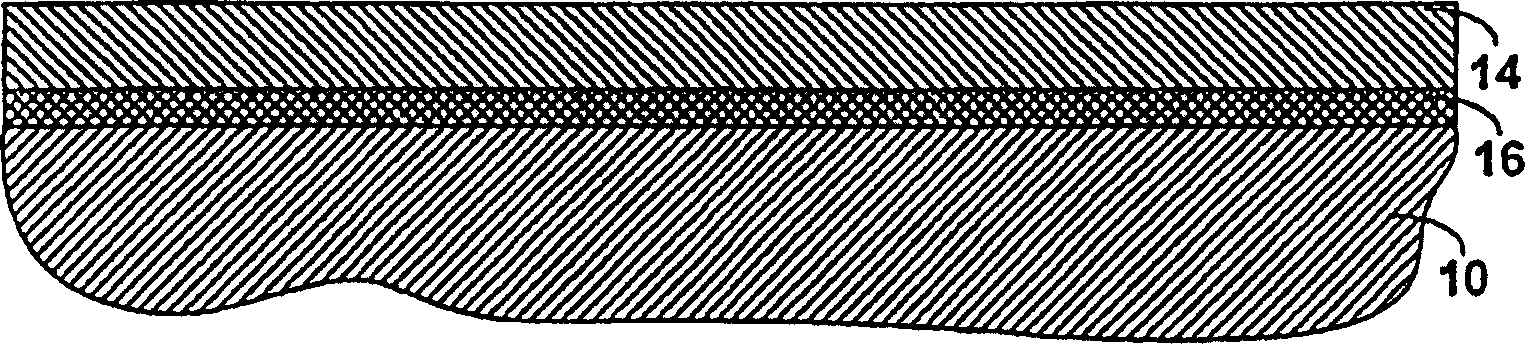

[0014] Now, will refer to Figure 1-6A , a first exemplary technique for fabricating high resistance resistors (in the range of 100k ohms - 1M ohms) on flexible substrate materials is described. figure 1 The flexible substrate material 10 on which the resistors are to be fabricated is illustrated. The flexible substrate 10 has a thickness of 0.5-3 mils and comprises a flexible plastic sheet that can be bent into a desired shape. A flexible substrate capable of bending or flexing is defined as a film or composition having a modulus of elasticity not exceeding 10,000 PSI at 23 degrees Celsius as tested by the standard flexural strength method. The flexible substrate material 10 is an electrically insulating material, preferably comprising a polymer film to which a conductive material can be adhered. The flexible substrate material 10 includes a modulus of elasticity, a coefficient of thermal expansion, and a coefficient of moisture expansion that minimize dimensional changes d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com