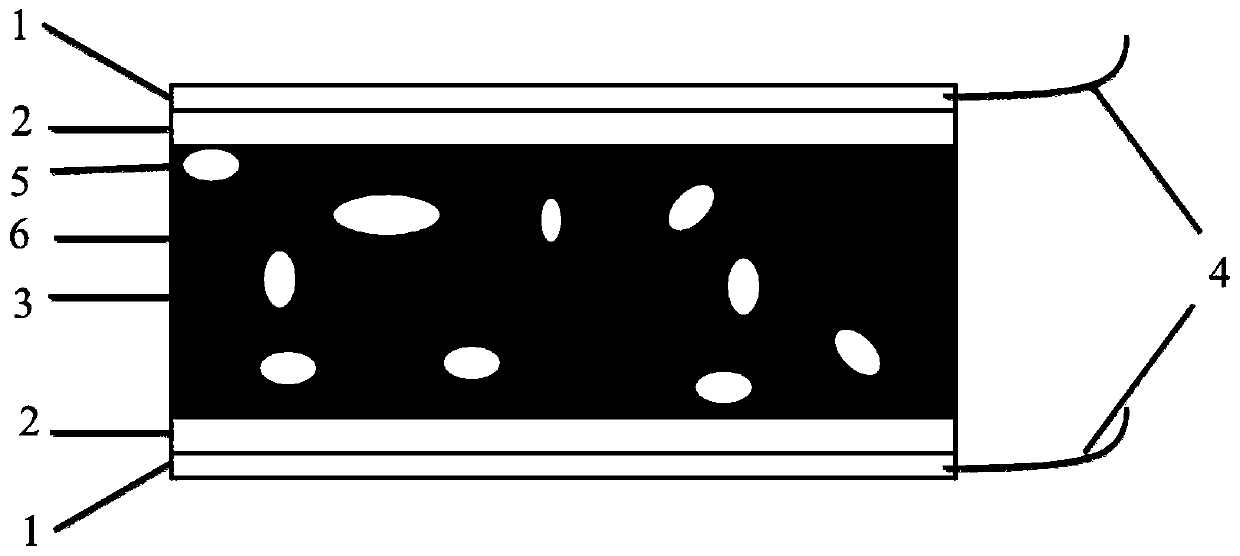

Wearable flexible capacitive pressure sensor and preparation method thereof

A pressure sensor, flexible capacitor technology, applied in the direction of sensors, chemical instruments and methods, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of graphene airgel;

[0049]Firstly, graphene oxide (GO) flakes were dispersed in deionized water and sonicated to prepare GO flake suspension (6 -1 ), then the GO flake suspension was reduced with L-ascorbic acid (the concentration ratio of L-ascorbic acid to GO suspension was 1:1), the mixture was sealed in a vial, and heated in an oil bath at 120 °C without any stirring. Heat treatment at ℃ for 4h;

[0050] In the next step, the obtained hydrogel was washed with deionized water, and finally, the hydrogel was first frozen for 20 h, and then freeze-dried for 48 h to obtain graphene airgel.

[0051] Preparation of 051GA / polydimethylsiloxane sponge;

[0052] The GA obtained in the step (1) is pulverized to the micron level, the fragmented GA is uniformly dispersed in ethanol, and the polydimethylsiloxane main agent is added to the GA suspension (the weight ratio of GA to PDMS solution is 10 / 1000), and heated at 80°C until the ethanol evaporates completely,...

Embodiment 2

[0057] 1) Preparation of graphene airgel;

[0058] GO flake suspension (10 mg ml -1 ), then the GO flake suspension was reduced with glucose (the concentration ratio of glucose to GO suspension was 5:1), the mixture was sealed in a vial, and heat-treated in an oil bath at 200 °C for 1 h without any stirring;

[0059] In the next step, the obtained hydrogel was washed with deionized water, and finally, the hydrogel was first frozen for 40 h, and then freeze-dried for 24 h to obtain graphene airgel.

[0060] 2) Preparation of GA / Ecoflex sponge;

[0061] The GA obtained in step (1) was pulverized to micron level. The fragmented GA was uniformly dispersed in ethanol, the Ecoflex solution was added to the GA suspension (the weight ratio of GA to Ecoflex solution was 50 / 1000), and heated at 120 °C until the ethanol evaporated completely. After cooling, add benzoyl peroxide to the mixed solution, and select sugar template technology to foam the polymer. After the sugar and polyme...

Embodiment 3

[0065] Preparation of graphene airgel;

[0066] Firstly, graphene oxide (GO) flakes were dispersed in deionized water and sonicated to prepare GO flake suspension (8 -1 ), then reduce the GO flake suspension with sodium citrate (concentration ratio of sodium citrate to GO suspension is 2:1), seal the mixture in a vial, and place it in an oil bath at 180°C without any stirring. Heat treatment at ℃ for 2h;

[0067] In the next step, the resulting hydrogel was washed with deionized water. Finally, the hydrogel was frozen for 30 h, and then freeze-dried for 36 h to obtain the graphene aerogel.

[0068] Preparation of GA / polyurethane sponge;

[0069] The GA obtained in step (1) was pulverized to micron level. The fragmented GA was uniformly dispersed in ethanol, the polyurethane solution was added to the GA suspension (the weight ratio of GA to polyurethane solution was 20 / 1000), and heated at 100 °C until the ethanol evaporated completely. After cooling, add sodium lauryl sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com