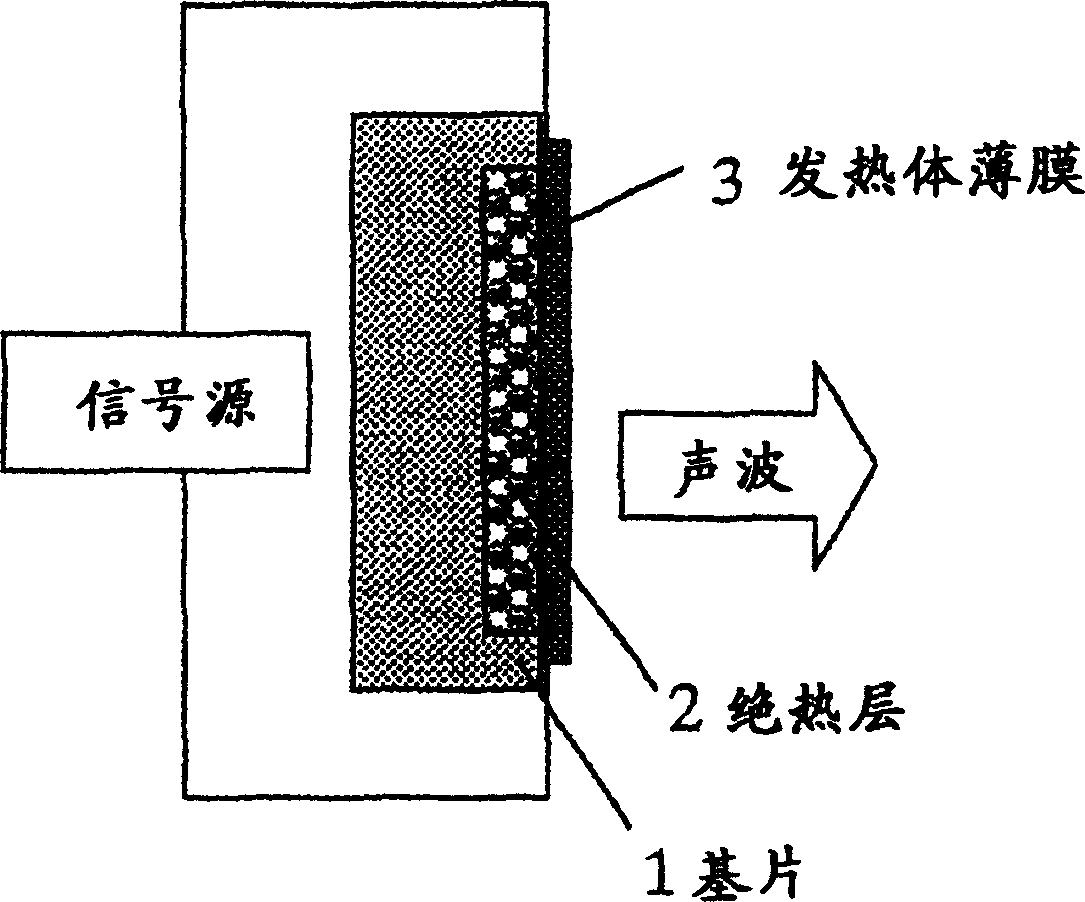

Thermally excited sound wave generating device

A technology of sound wave generation and thermal excitation, which is applied in the direction of sensors, electrical components, sensor parts, etc., can solve the problems that the sound pressure level cannot meet the needs, there is not much development prospect, and the DC component cannot be fully released.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

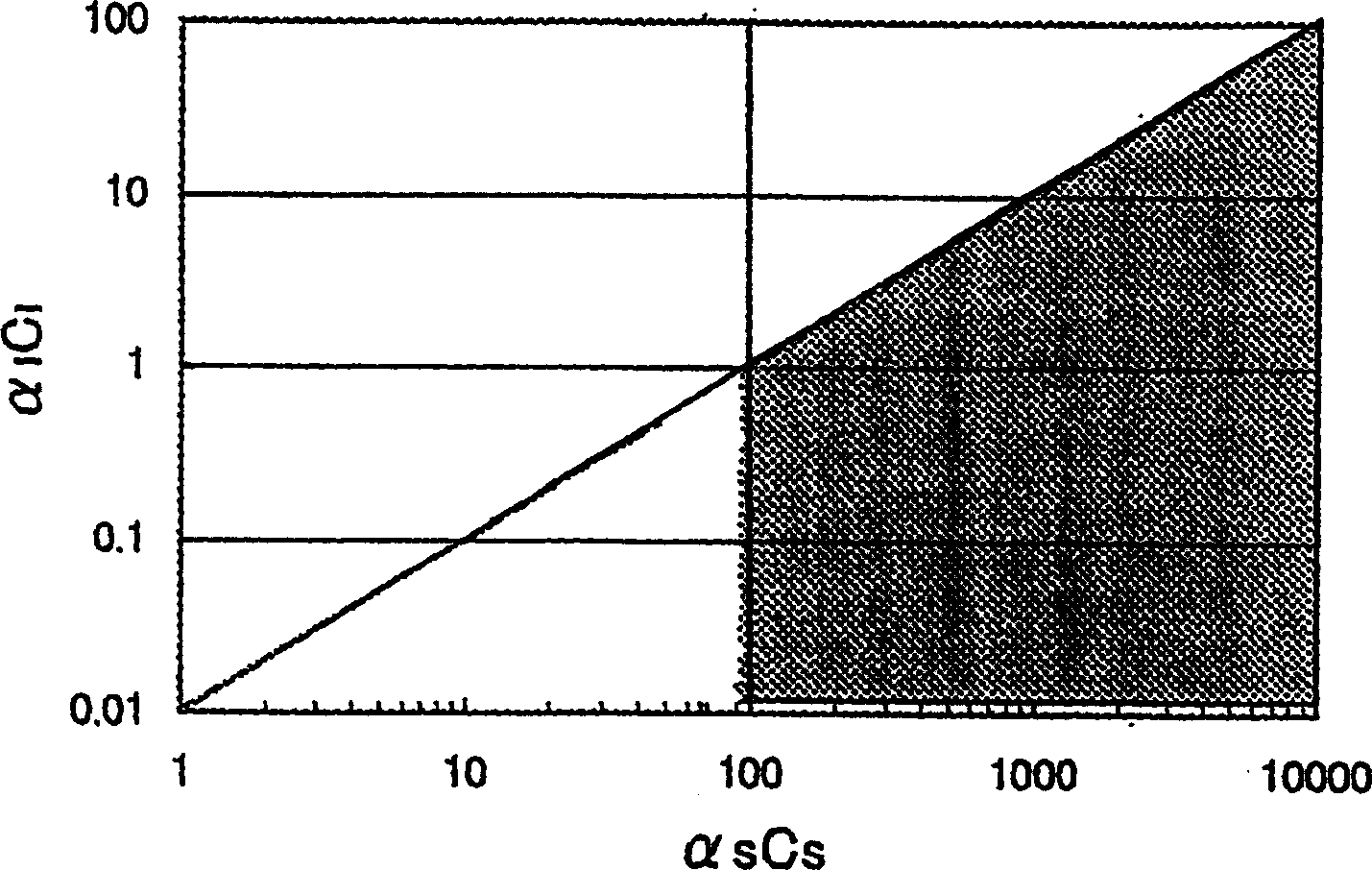

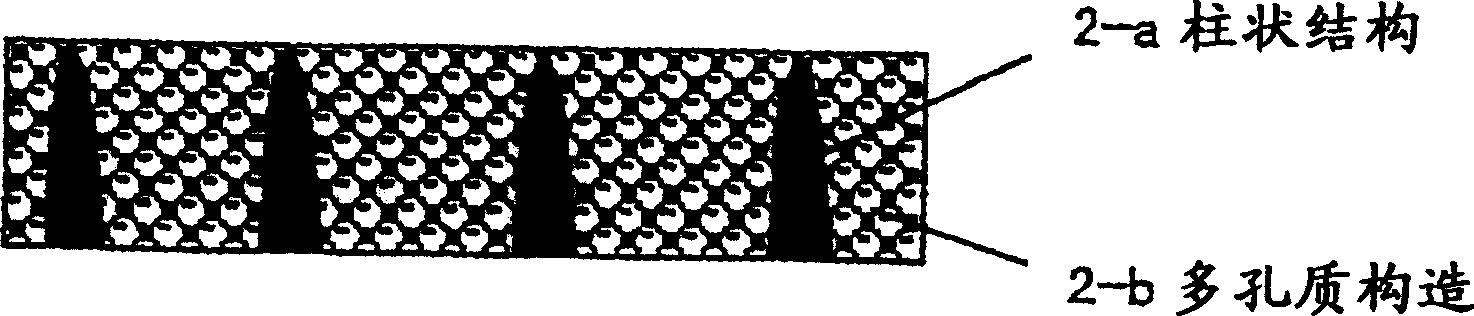

[0045] P-type (100) single crystal silicon substrate (80~120Ωcm, α s C s =286×10 6 ) was used as a contact electrode during anodic oxidation treatment, and a film with a thickness of 300 nm was formed by vacuum deposition of Al. Then this substrate is placed in the solution of HF (55%):EtOH=1:1, with Pt as the opposite electrode, at a current density of 100mA / cm 2 Anodizing treatment was carried out for 8 minutes to form a porous silicon layer with a thickness of about 50 μm (α 1 C 1 =0.06×10 6 ). Finally, a 50nm-thick W as a heating element film was formed on the porous silicon layer by sputtering, and a 5mm□ area element was fabricated.

Embodiment 2

[0047] On a pure copper substrate (thickness 1mm, α s C s =1393×10 6 ) The upper surface is coated with polyimide with a thickness of 50 μm (α 1 C 1 =0.26×10 6 ). Finally, a 50nm-thick W film was formed on the polyimide by sputtering as a heating element film, and a 5mm□ area element was fabricated.

Embodiment 3

[0049] On a pure copper substrate (thickness 1mm, α s C s =1393×10 6 ) on the upper surface of SiO with a thickness of 2 μm formed by sputtering 2 Layer (α 1 C 1 =3.2×10 6 ). Finally on SiO 2 A 50nm-thick W film was formed as a heating element by sputtering, and a 5mm□ area element was fabricated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com