Concentrated sulfuric acid resistant fluoro-rubber sealing spacer

A technology of sealing gasket and fluororubber, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of expensive gaskets, high maintenance costs, and difficulty in ensuring the normal use of gaskets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 60 parts of tetrapropyl fluororubber, 40 parts of 23 type fluorine rubber, 2.5 parts of vulcanizing agent dicumyl peroxide, 4.5 parts of co-curing agent triallyl cyanurate, 15 parts of filler spray carbon black, filler barium sulfate 18 parts and 2 parts of lubricant polyethylene wax, put in a container, stir and mix evenly, then molded, and after secondary hot air treatment, the finished product of concentrated sulfuric acid resistant fluororubber sealing gasket is obtained.

Embodiment 2

[0021] Take 65 parts of tetrapropylene fluoro rubber, 35 parts of 23 type fluoro rubber, 2.8 parts of dicumyl peroxide, 4 parts of triallyl cyanurate, 18 parts of spray carbon black, 15 parts of barium sulfate and 2.2 parts of polyethylene wax Put it in a container, stir and mix evenly, mold it, and heat it for the second time to get the finished product of concentrated sulfuric acid resistant fluororubber sealing gasket.

Embodiment 3

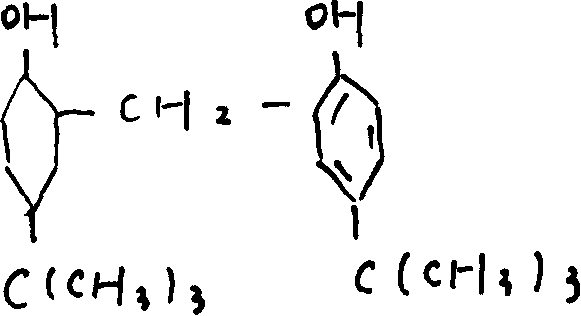

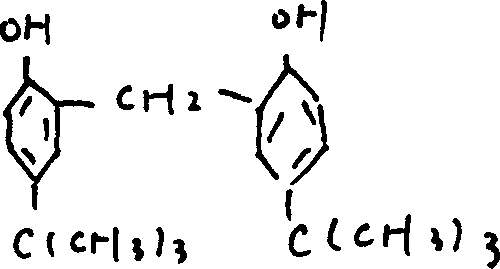

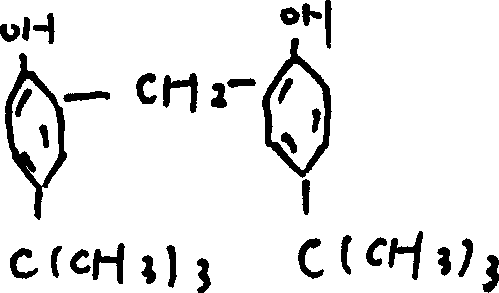

[0023] Take 63 parts of tetrapropylene fluoro rubber, 38 parts of 23 type fluoro rubber, 2.6 parts of dicumyl peroxide, 4.3 parts of triallyl cyanurate, 17 parts of spray carbon black, 16 parts of barium sulfate, 2.1 parts of polyethylene wax 1 part and 0.6 part of thickening aid, placed in a container, stirred and mixed evenly, molded, and treated with hot air for the second time to obtain the finished product of concentrated sulfuric acid resistant fluororubber sealing gasket. The tackifier is mixed with asphalt and resin, and the mixing weight ratio of the two is 1:2-5. The structural formula of described resin is:

[0024]

[0025] Note:

[0026] Type 23 fluororubber is a rubbery copolymer prepared by suspension polymerization of vinylidene fluoride and chlorotrifluoroethylene [Rubber Industry Handbook Revised Edition Volume 1, Raw Rubber and Skeleton Materials Page 606, Chemical Industry Press , Xie Suizhi, Liu Dengxiang, Zhou Mingluan, the third printing in Beijing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com