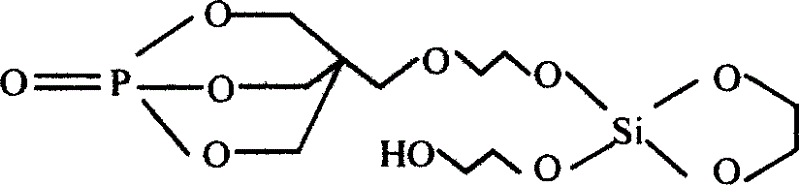

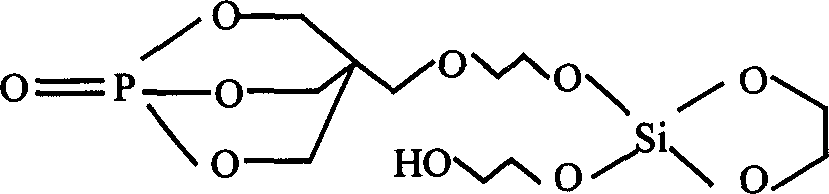

Phosphosilicate containing fire retardant and its prepn process

A technology of flame retardant and silicate, which is applied in the field of phosphorus-containing silicate flame retardant and its preparation, can solve the problems of thermal stability and migration affecting material performance and surface finish, and achieve the purpose of inhibiting thermal oxidation degradation Reaction, less corrosive gas, effect of preventing mass loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

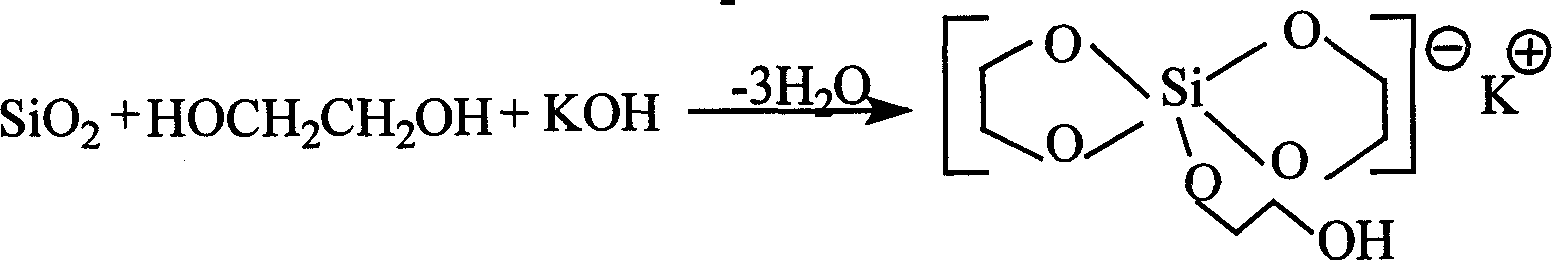

Method used

Image

Examples

Embodiment 1

[0018] First, 10.0g (0.05mol) of 1-oxo-1-phospha-2,6,7-trioxabicyclo[2.2.2]-4-chloromethyloctane was stirred and dissolved in 50ml of Dimethylformamide, then add 12.5g (0.05mol) of pentacoordinate silicon potassium compound, stir vigorously, then raise the temperature to 65°C for constant temperature reaction; when the pH is 7, stop the reaction, cool down to room temperature, suction filter, remove The salt generated therein is added to the filtrate with 100ml of reverse phase precipitation reagent acetone to produce a large amount of white precipitated matter, which is filtered, and the white matter is placed in a vacuum drying oven and dried at a constant temperature of 70°C for 24 hours to obtain the white granular matter which is the present invention. The yield of the phosphorus-containing silicate flame retardant is 80%. The analysis test results are as follows:

[0019] Fourier infrared: 3384cm -1 、2956cm -1 、1465cm -1 、1229cm -1 、1094cm -1 、1045cm -1 、952cm -1...

Embodiment 2

[0023] First, 2.0g (0.01mol) of 1-oxo-1-phospha-2,6,7-trioxabicyclo[2.2.2]-4-chloromethyloctane was stirred and dissolved in 5ml of Dimethylacetamide, then add 5g (0.02mol) of pentacoordinate silicon potassium compound, stir vigorously, and then raise the temperature to 60°C for constant temperature reaction; when the pH is 7, stop the reaction, cool down to room temperature, and remove it by suction filtration. Generated salt, then add 25ml of reverse-phase precipitation reagent acetone to the filtrate, produce a large amount of white precipitated matter, filter, put the white matter in a vacuum drying oven for 30 hours at a constant temperature of 60°C, and obtain the white granular matter that is the product of the present invention. A phosphorus-containing silicate flame retardant is described with a yield of 76%.

Embodiment 3

[0025] First, 2.0g (0.01mol) of 1-oxo-1-phospha-2,6,7-trioxabicyclo[2.2.2]-4-chloromethyloctane was stirred and dissolved in 15ml of Dimethyl sulfoxide, then add 3.75g (0.015mol) of pentacoordinate silicon potassium compound, stir vigorously, then raise the temperature to 70°C for constant temperature reaction; when the pH is 7, stop the reaction, cool down to room temperature, suction filter, remove The salt generated therein is added to the filtrate with 30ml of reverse-phase precipitation reagent acetone to produce a large amount of white precipitated matter, which is filtered, and the white matter is placed in a vacuum drying oven and dried at a constant temperature of 80°C for 18 hours to obtain white granular matter which is the present invention. The yield of the phosphorus-containing silicate flame retardant is 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com