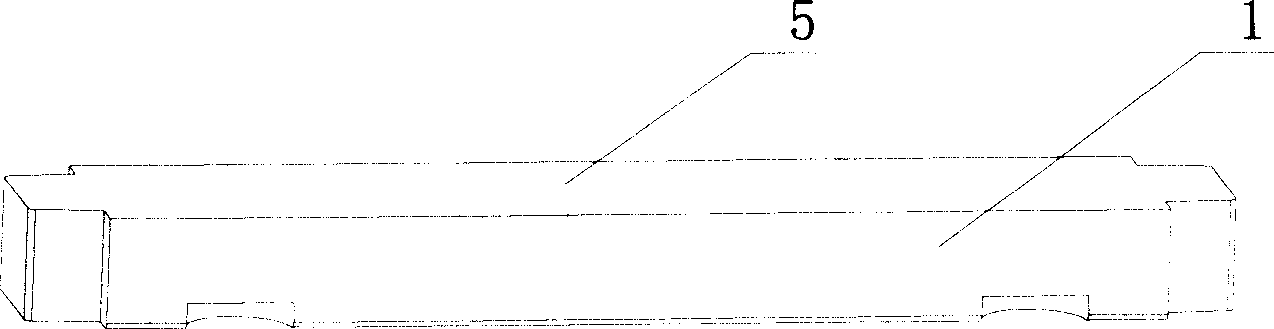

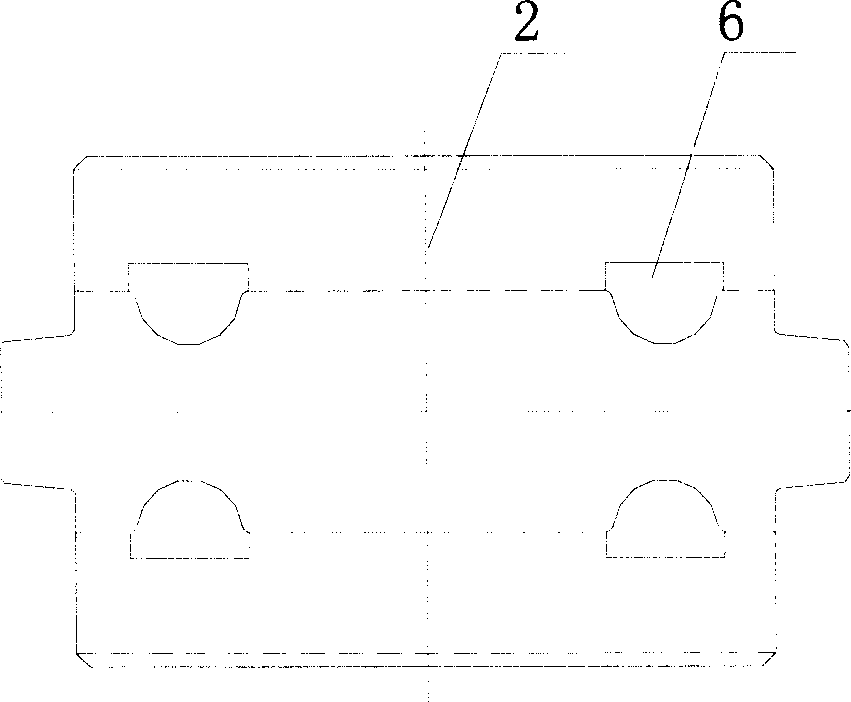

Elevator synthetic counterpoise and its manufacturing method

A production method and technology for counterweights, which are used in transportation and packaging, lifting equipment in mines, etc., can solve the problems that cannot be used as a substitute for elevator counterweights, are not suitable for elevator counterweights, and have limited material sources. To achieve the effect of compact structure, simple and easy production method and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

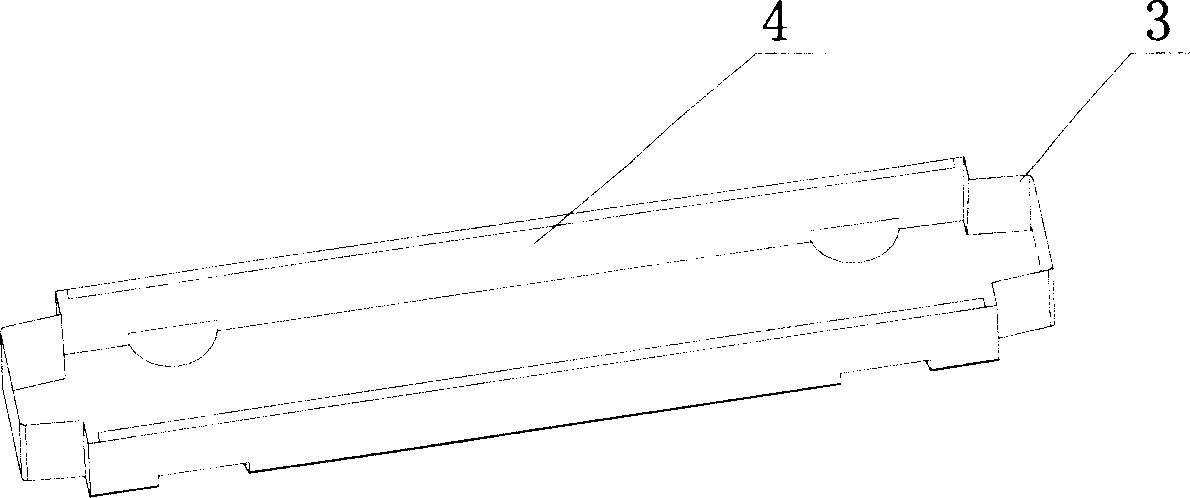

Embodiment 1

[0013] When making a single-block elevator with a combined counterweight of 42kg, the shell weighs 2.5kg, steel slag (about 50-60% iron content) 28kg, cement 4kg, steel bar 0.5kg, iron powder 5kg, water 2kg, Apply 0.1% anti-rust paint.

Embodiment 2

[0015] When making a single-block elevator composite counterweight of 42kg, the shell weighs 4kg, steel slag (about 50-60% iron content) 24kg, cement 5kg, steel bar 1kg, iron powder 6kg, water 2kg, and the shell is coated with anti-corrosion Rust paint 0.1%.

Embodiment 3

[0017] When the counterweight of a single-block elevator is made to be 52kg, the shell weighs 2.5kg, steel slag (about 70% iron content) 32kg, cement 5kg, steel bar 1kg, iron powder 9kg, water 2.5kg, and the shell is coated with anti-corrosion Rust paint 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com