Process for making a fluoropolymer having nitrile end groups

A technology of fluoropolymers and end groups, which is applied in the field of preparing fluoropolymers with nitrile end groups, and can solve problems such as difficult handling, toxicity, and inconvenient manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

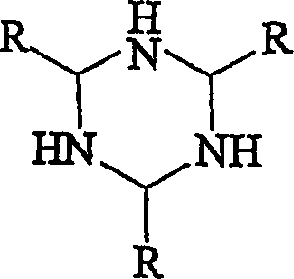

Method used

Image

Examples

Embodiment 1

[0068] Under anaerobic conditions, put 2800ml of deionized water into a 4-liter kettle. Add 9 grams of C 7 f 15 COONH 4 (APFO) and 6 grams of KSCN. After heating to 70°C, 96 grams of tetrafluoroethylene (TFE) and 247 grams of perfluoromethyl vinyl ether (PMVE) were added. The reaction was initiated by adding 15 grams of ammonium persulfate (APS) dissolved in 110 ml of deionized water. At a pressure of 12 bar and a temperature of 70°C, 23 grams of TFE and 14 grams of PMVE were fed in 363 minutes. The solid content of the formed latex is 4.3%, and with MgCl 2 The solution coagulates. The polymer was dried at 130°C.

[0069] FT-IR analysis showed a significant amount of nitrile functional groups (at 2262 cm -1 peak). Following the above method, a value of 0.039 was obtained.

Embodiment 2

[0071] Put 2900ml of deionized water into a 4 liter reactor. Add 9 grams of C 7 f 15 COONH 4 (APFO) and 6 grams of KSCN. After heating to 70°C, 94 grams of TFE and 243 grams of perfluoromethyl vinyl ether (PMVE) were added. The reaction was initiated by adding 6 grams of ammonium persulfate (APS) dissolved in 50 ml of deionized water.

[0072] At a pressure of 16 bar and a temperature of 70°C, 490 grams of TFE and 418 grams of PMVE were fed in 404 minutes. The solid content of the formed latex is 21.6%, and with MgCl 2 The solution coagulates. The polymer was dried at 130°C.

[0073] FT-IR analysis of the nitrile end group value of the isolated polymer showed a significant amount of nitrile functionality (at 2262 cm -1 peak). Following the above method, a value of 0.008 was obtained.

[0074] The Mooney (1+10@121°C) viscosity is 99.

Embodiment 3

[0076] Put 2700ml of deionized water into a 4 liter reactor. Add 9 grams of APFO and 5 grams of KOCN. After heating to 70°C, 97 grams of TFE and 253 grams of PMVE were added. The reaction was initiated by adding 6 g of APS dissolved in 50 ml of deionized water. At a pressure of 12 bar and a temperature of 70°C, 51 grams of TFE and 43 grams of PMVE were fed in 73 minutes. The solids content of the formed latex was 5.1%. The polymer was dried at 130°C.

[0077] FT-IR analysis showed a nitrile end group value of 0.067.

[0078] The Mooney (1+10@121°C) viscosity is 39.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com