Glycerol diaester flavouring oil and production thereof

A technology of diacylglycerol and seasoning oil, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of perishable and tasteless, opaque, affecting the use effect of seasoning oil, etc., to increase appetite, prevent obesity, improve quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Heat 300 grams of diacylglyceride to 120°C, add 15 grams of dried chili powder crushed to 200 mesh and 15 grams of dried Zanthoxylum bungeanum powder crushed to 200 mesh, extract for 40 minutes under a negative pressure of 50mmHg, cool to 60°C, and use a plate-type airtight filter Filter to remove solid particles above 220 mesh, let stand for 4 hours, pump out the upper clear night, enter the centrifuge, and centrifuge for 30 minutes at a speed of 4000rpm to remove solid impurities. After centrifugation, the clear liquid is mixed with 100 g Blend pure sesame sesame oil, add 0.12 grams of natural vitamin E and 0.05 grams of ascorbyl palmitate, mix well, use ceramic roll-type ultrafiltration membranes, and the working conditions of three-stage tubular ceramic ultrafiltration membranes are: use a pore size of 0.05um Ultrafiltration membrane, working pressure 2 kg / cm 2 After filtering, the diacylglyceride seasoning oil (see Table 1) is obtained.

[0038] Natural vitamin E ...

example 2

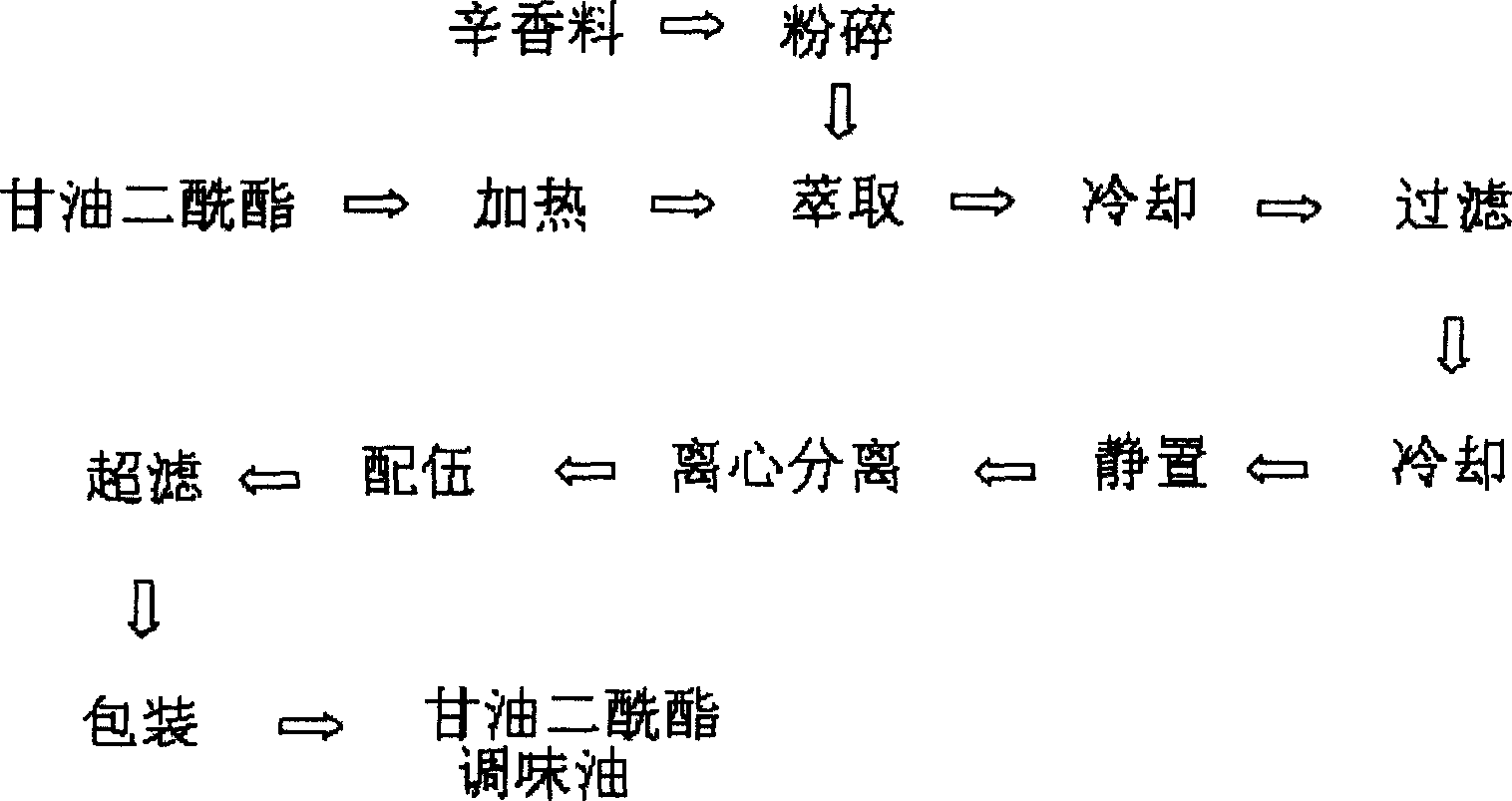

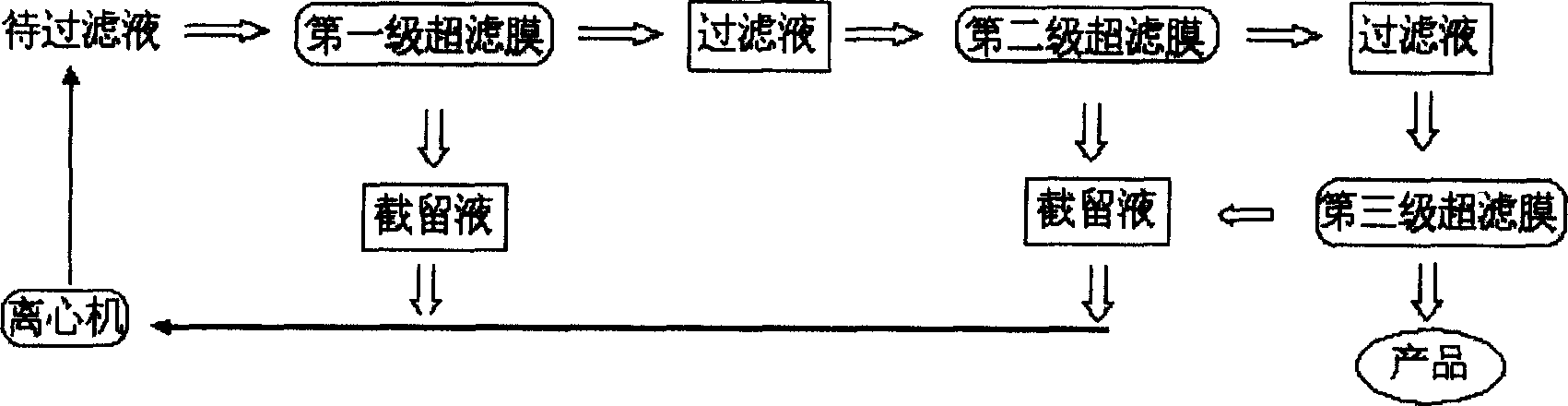

[0040] combine figure 1 Process flow chart for the preparation of diacylglyceride seasoning oil, figure 2 In the preparation of diacylglyceride seasoning oil, the process flow chart of removing microgum by three-stage ultrafiltration method describes the present invention in detail.

[0041]Take 300 grams of diacylglyceride and heat it to 120°C, add 10 grams of dried chili powder crushed to 200 mesh, 5 grams of dried Zanthoxylum bungeanum powder crushed to 200 mesh, and 5 grams of raw green onion crushed to 200 mesh, keep the temperature, under a negative pressure of 70mmHg Extract for 40 minutes, cool to 70°C, use a plate-type airtight filter to remove solid particles above 220 mesh, let it stand for 6 hours, pump out the supernatant, enter the centrifuge, and centrifuge for 30 minutes at a speed of 4000rpm. Minutes, remove solid impurities, add 100 grams of pure sesame oil to reconcile, and add 0.12 grams of natural vitamin E (purity 90 parts) and 0.05 grams of ascorbyl pa...

example 3

[0043] Heat 200 grams of first-grade soybean oil to 120°C, add 15 grams of dried chili powder, 10 grams of dried Zanthoxylum bungeanum pepper powder, and 10 grams of raw green onion. The above seasonings are crushed to 200 mesh, extracted under a negative pressure of 60mmHg for 40 minutes, and cooled to 60°C. After filtering through a plate-type airtight filter and centrifugal separation (4000rpm, 15 minutes) to remove solid impurities, blend with 700 grams of diacylglycerides and 100 grams of pure sesame oil, and add 0.15 grams of antioxidant TBHQ and 0.1 grams of ascorbyl palmitate, Mix evenly, use ceramic roll-type ultrafiltration membrane (0.05um membrane, working pressure 2 kg / cm 2 ) to obtain diacylglyceride seasoning oil after filtration (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com