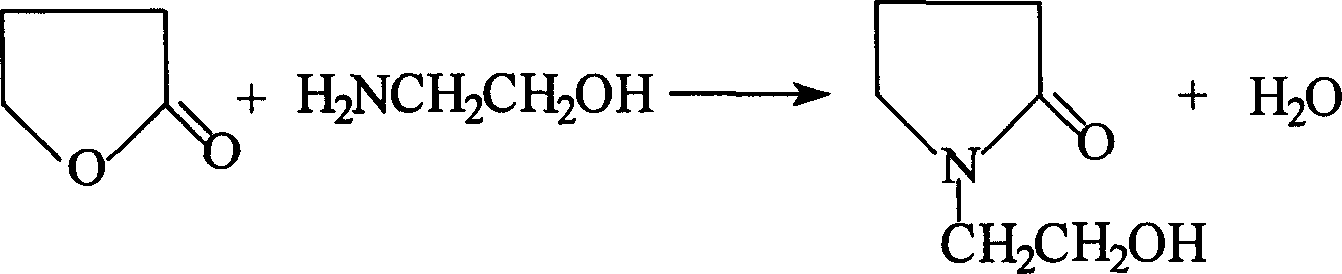

Gas-phase production of N-hydroxyethyl-pyrrolidone

A technology of hydroxyethylpyrrolidone and gas phase, applied in the direction of organic chemistry, etc., can solve problems such as limiting the application range of products, having peculiar smell, and affecting the quality of final products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Example 1: Catalyst Preparation

[0017] Y-type molecular sieve modification: Weigh a certain amount of NaY (Si / A1=4.7, NaY 2 O content is about 13%), REY molecular sieve, respectively use alkali metal or alkaline earth metal nitrate to make 10% ~ 20% (m) aqueous solution, and impregnate the molecular sieve at 60 ℃ ~ 80 ℃ under slow stirring for more than 10h, Let stand overnight, then slowly evaporate to dryness, dry at 110°C for 8 hours, calcinate at 500°C in an air atmosphere for 4 hours, crush and sieve to obtain Y-type molecular sieves with different cation compositions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com