Pulse burial arc welding process and welding device for boiler membrane type tube panels and tube rows

A submerged arc welding machine and membrane-type technology, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of increasing the manufacturing cost of fins, failing to meet the requirements of welding penetration, and increasing the difficulty of welding and assembly. Achieve the effect of improving welding quality, meeting production requirements, and improving weld formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments Take the welding of 38×7 water wall tubes and fins with a thickness of 9.5 mm as an example.

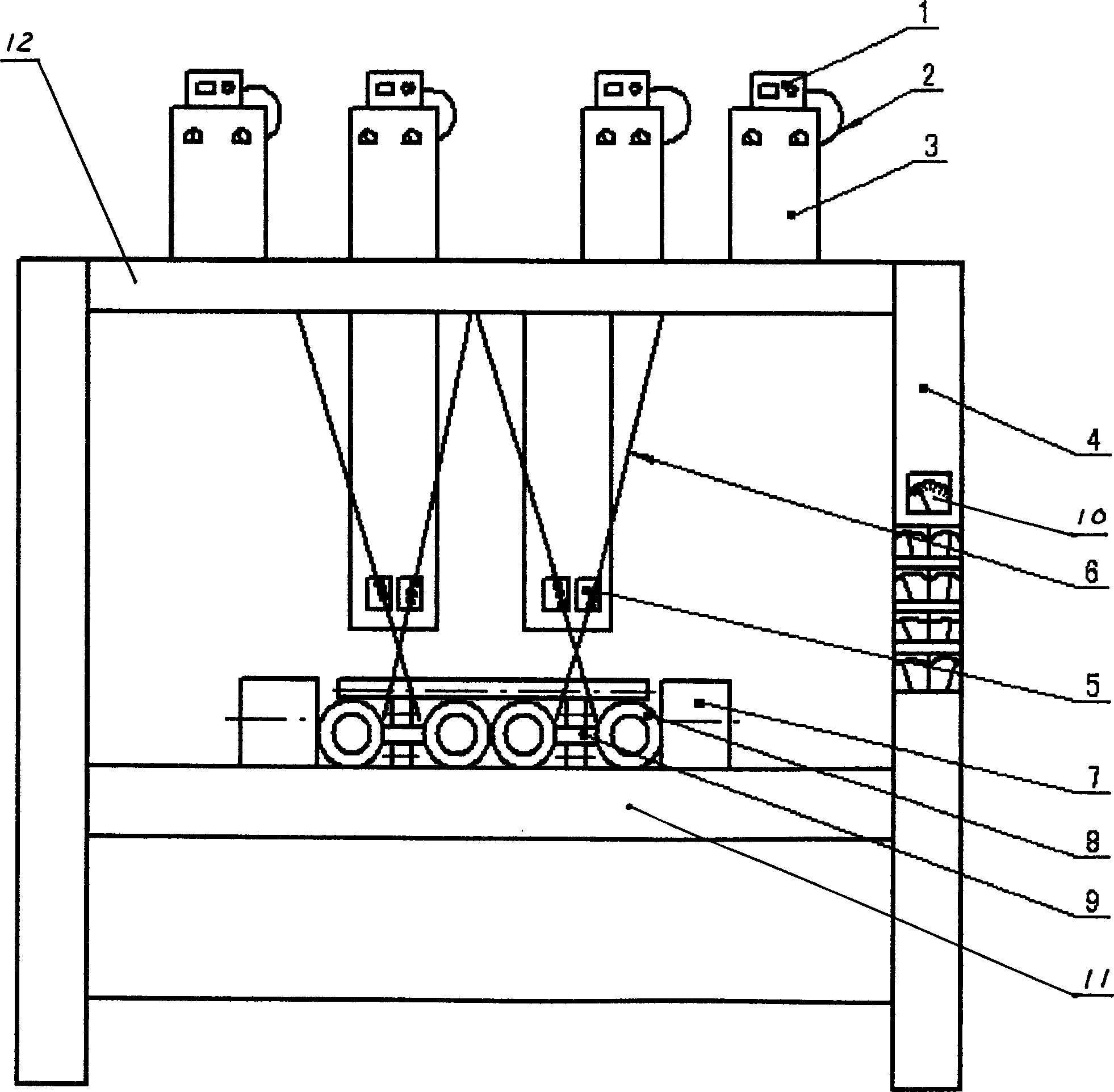

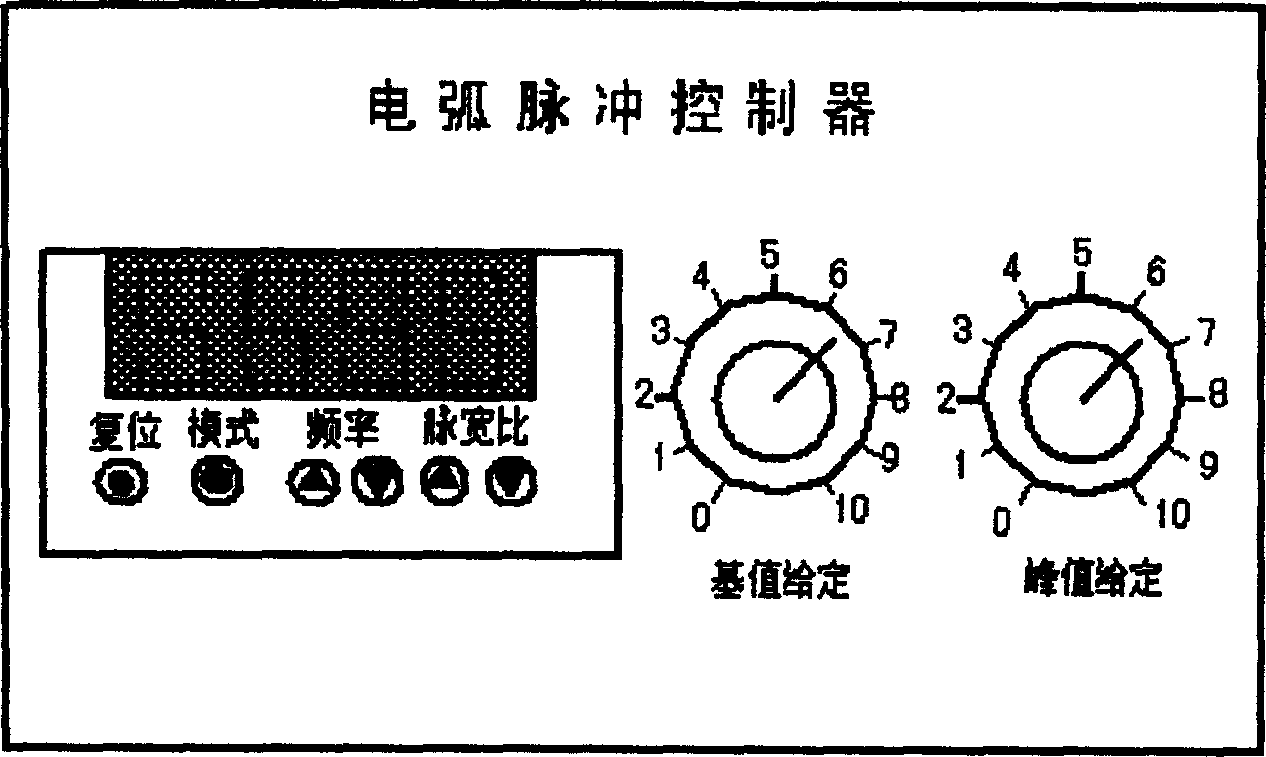

[0017] Such as figure 1 As shown, it is a schematic diagram of a boiler membrane tube panel tube row pulse submerged arc welding machine. The boiler membrane tube panel tube row pulse submerged arc welding machine consists of an arc pulse controller 1, a welding power source 3, a welding frame 4, and a wire feeding mechanism 5. Welding wire 6 and welding tooling 7 are composed of 4 welding power sources 3 installed on the upper end of the beam 12 of the welding frame 4, connected with the welding switch 10 on the welding frame 4, and an electric arc is provided at the upper end of each welding power source 3 The pulse controller 1 is connected with the welding power supply 3 through the connection line 2, a welding torch is arranged at the lower end of each welding power supply 3, and the wire feeding mechanism 5 is installed on the welding frame 4, and the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com