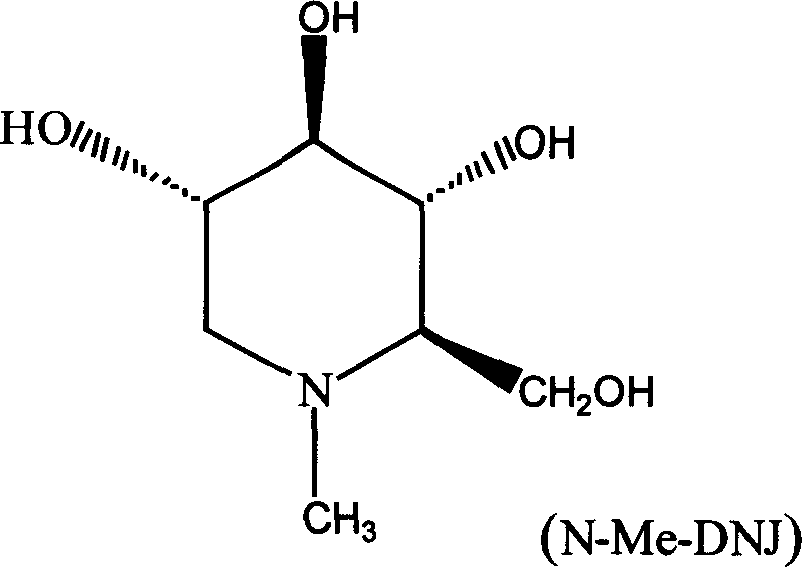

Method for extracting and preparing N-methyl-1-deoxy noijirimycin

A technology of deoxynojirimycin and methyl, which is applied in the direction of organic chemistry and can solve the problems of low yield, inability to realize industrial production, and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of N-methyl-1-deoxynojirimycin from mulberry leaves.

[0017] Specific preparation process:

[0018] One kilogram of mulberry leaves, add 15 times of water, soak, heat and extract twice, each time for 2 hours, filter, concentrate to about 1 liter, add 1 liter of ethanol, and separate the supernatant with a strong acid cation exchange resin column, first Elute with 8 liters of water, then elute with 0.3M ammonia water, collect the ammonia water eluate, add 10ml each of formaldehyde and acetic acid after concentration, keep warm at 80°C for 3 hours, separate with strong acid anion exchange resin, elute with water, and Every 300ml is collected as a part, and detected by thin layer chromatography (TLC method), PrOH-AcOH-H 2 O (4:1:1) is the developer. The combined Rf value was 0.23, and the ninhydrin showed a purple-red part, which was concentrated to obtain N-methyl-1-deoxynojirimycin (1510 mg).

Embodiment 2

[0020] Extract N-methyl-1-deoxynojirimycin from Cortex Morus alba.

[0021] Specific preparation process:

[0022] One kilogram of Cortex Mori, add 10 times the amount of water, heat at 95°C to extract twice, each time for 2 hours, filter, concentrate to 1 liter, add 1 liter of ethanol, and separate the supernatant with a strong acid cation exchange resin column , first eluted with 5 liters of water, then eluted with 0.5M ammonia water, collected the ammonia water eluate, concentrated, added 15ml each of formaldehyde and formic acid, heated at 60°C for 5 hours, separated with strong acid anion exchange resin, and eluted with water. Collect every 300ml as a part, detect with thin layer chromatography (TLC method), PrOH-AcOH-H 2 O (4:1:1) is the developer. The combined Rf value was 0.23, and the ninhydrin showed a purple part, which was concentrated to obtain N-methyl-1-deoxynojirimycin (1780 mg).

Embodiment 3

[0024] N-methyl-1-deoxynojirimycin was extracted by soaking at room temperature.

[0025] Specific preparation process:

[0026] One kilogram of mulberry leaves, 15 times of water, extracted twice at room temperature, 24 hours each time, filtered, concentrated to about 1 liter, added 1 liter of methanol, and the supernatant was separated with a strong acid cation exchange resin column, and first eluted with 5 liters of water , then elute with 0.2M ammonia water, collect the ammonia water eluate, add 10ml each of formaldehyde and acetic acid after concentration, heat at 70°C for 5 hours, separate with strong acid anion exchange resin after concentration, and elute with water, with each 300m1 as a part Collect, detect with thin layer chromatography (TLC method), PrOH-AcOH-H 2 O (4:1:1) is the developer. The combined Rf value was 0.23, and the ninhydrin showed a purple-red part, which was concentrated to obtain N-methyl-1-deoxynojirimycin (950 mg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com