Cation dye for dyeing and finishing wool real silk textile

A technology for cationic dyes and textiles, applied in the field of cationic dyes, which can solve the problems of large fiber damage, inability to transfer dyeing to improve unevenness, and fiber damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

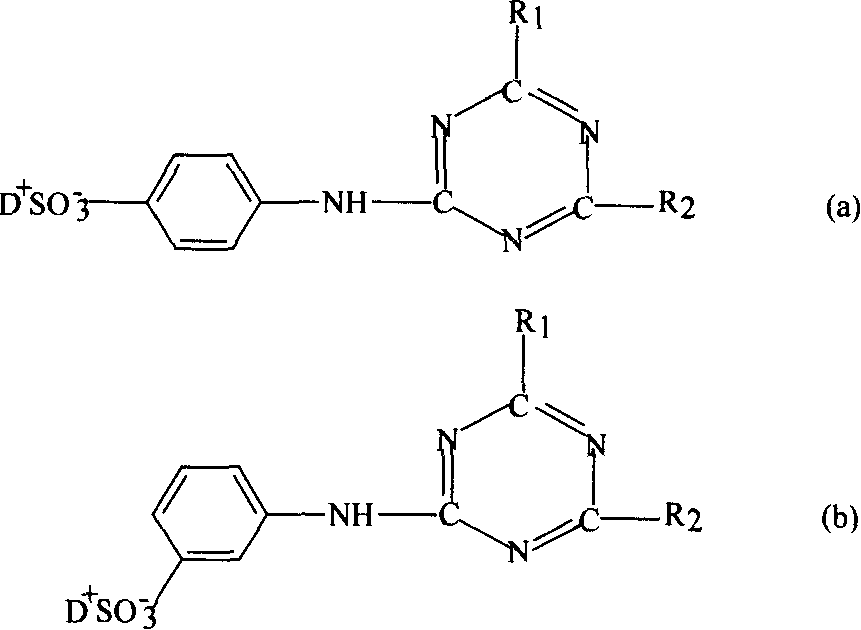

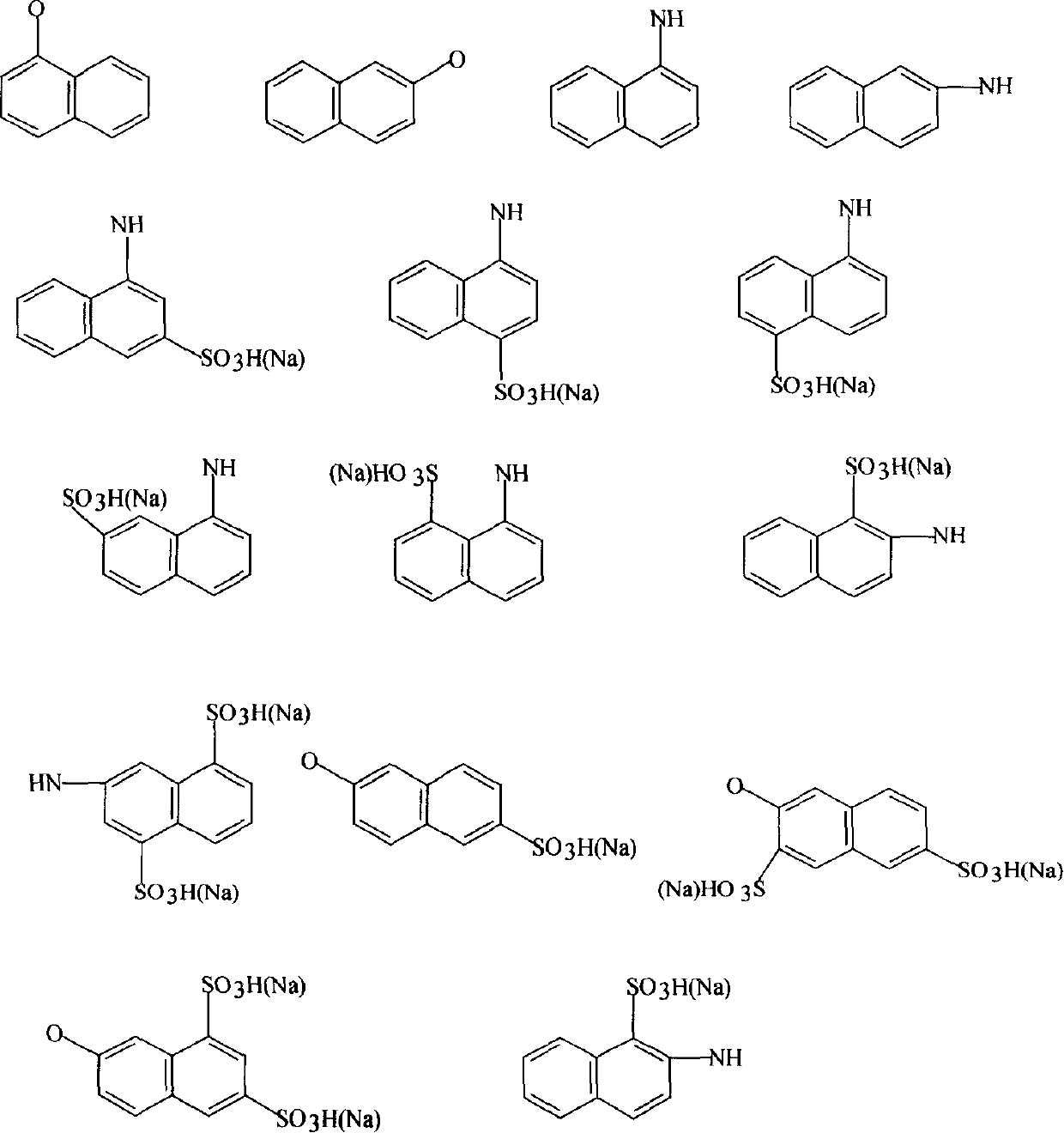

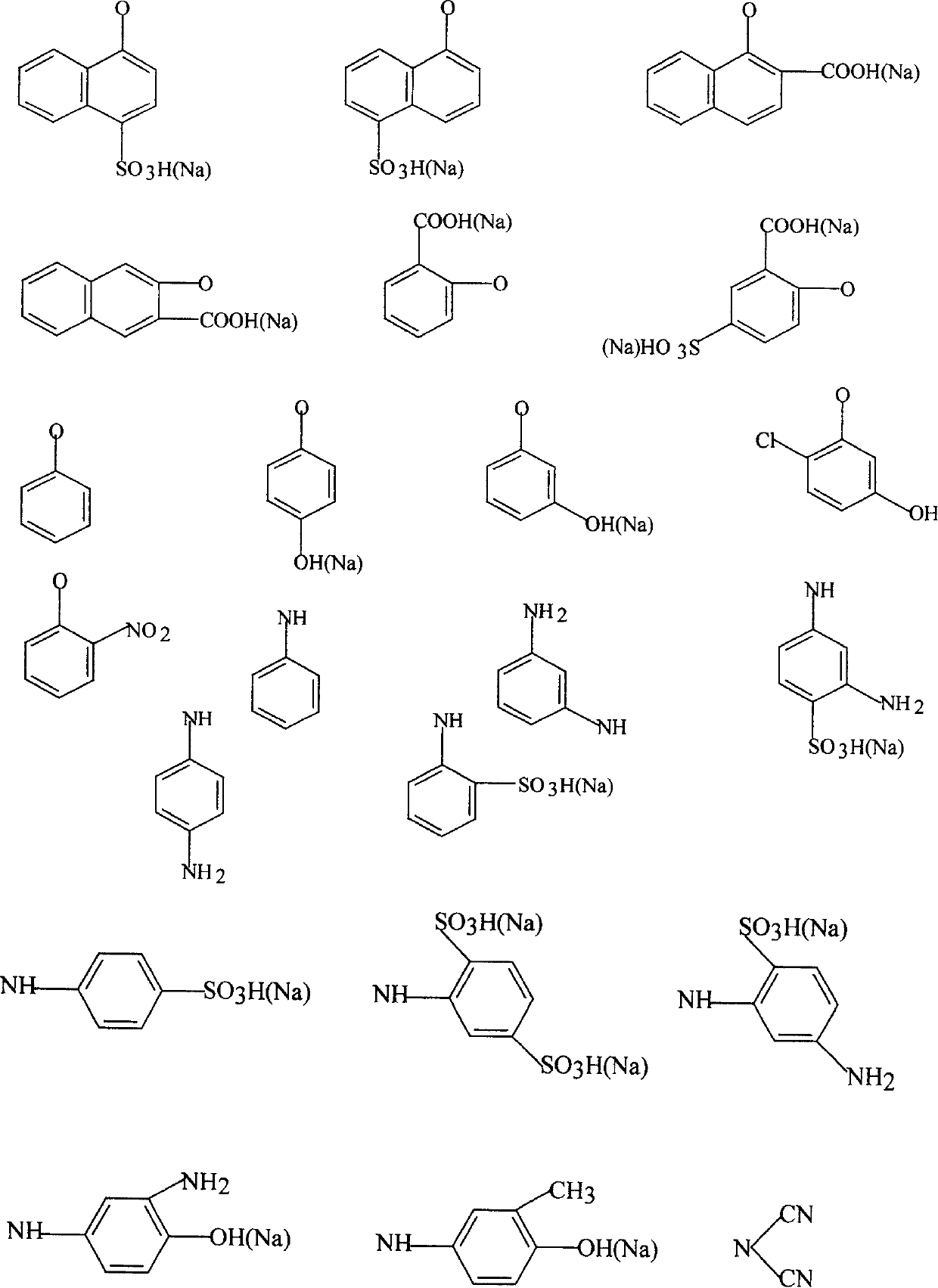

Method used

Image

Examples

example 1

[0201] Add 400 grams of water in the flask, add 20 grams of the original powder of Basic Orange 21# under stirring, stir and heat up until Basic Orange 21# is completely dissolved, cool to 20 degrees, add 30 grams of sodium sulfanilic acid, stir for 1 Hour, add 20 grams of cyanuric chloride again, add and finish 25 degrees of insulation for 6 hours, obtain (F).

[0202] Add 100 grams of water in the flask, add 18.7 grams of 2-naphthol, slowly add 32 grams of sodium hydroxide (the weight percent concentration is 30%) under stirring, heat up to 2-naphthol and all dissolve, then cool to normal temperature, add 100 grams of water (G).

[0203] In the flask, add 400 grams of water and the intermediate product (F), add (G) at 25 degrees, heat up to 50 degrees after the addition, stir and react for 5 hours, when the pH=6-7 remains unchanged for half an hour, lower the temperature To normal temperature, vacuum filtration, drying and pulverizing, get 32 grams of dyestuff of the pres...

Embodiment 2

[0205] Cationic dyes for hair of the present invention are directly used for the dyeing of wool (silk, camel hair, rabbit hair, etc.), and can also be used for fur dyeing, and the dyeing quality detection is as Table 1:

[0206]

Embodiment 3

[0208] Cationic dyes for wool of the present invention are directly used for the blended fabric dyeing of wool and acrylic fiber, and its dyeing quality detection is as table two:

[0209] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com