Continuous boiling method and its device for semi chemical mechanical slurry of long bast fiber raw material

A bast fiber and chemical-mechanical technology, which is applied in the field of semi-chemical mechanical pulp continuous cooking of long bast fiber raw materials and its devices, can solve the problems of high price, economic loss, complex structure, etc., and achieves low production cost and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

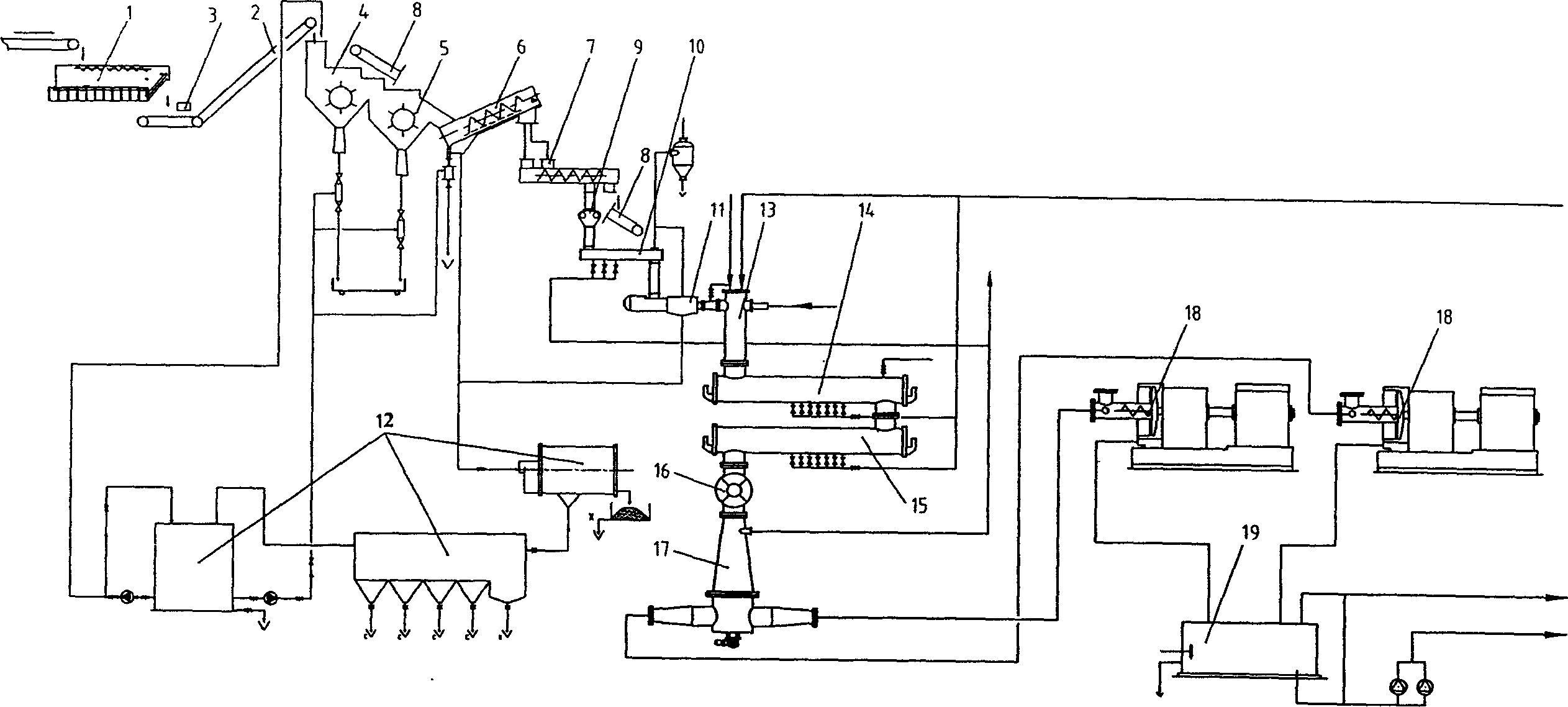

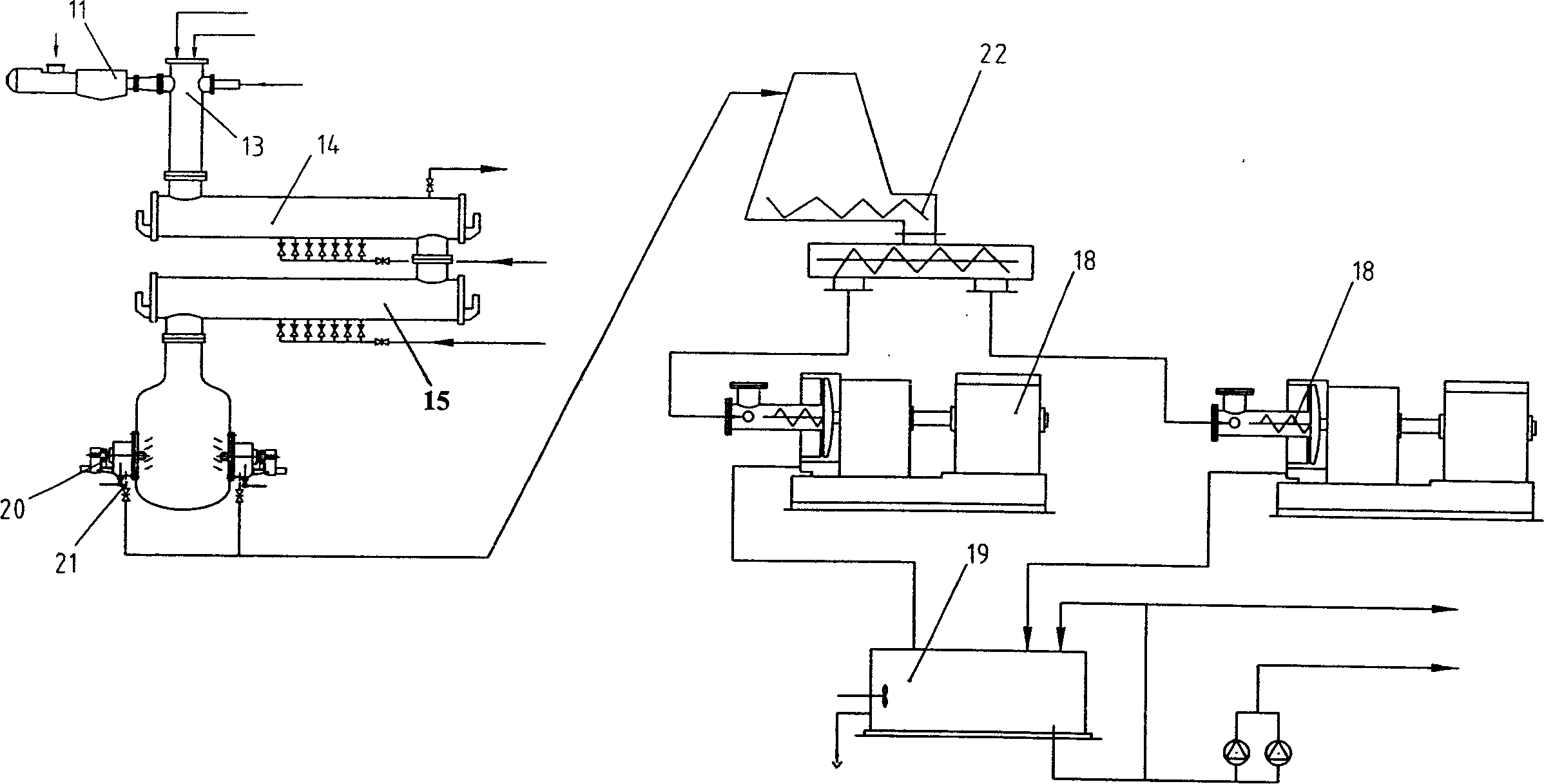

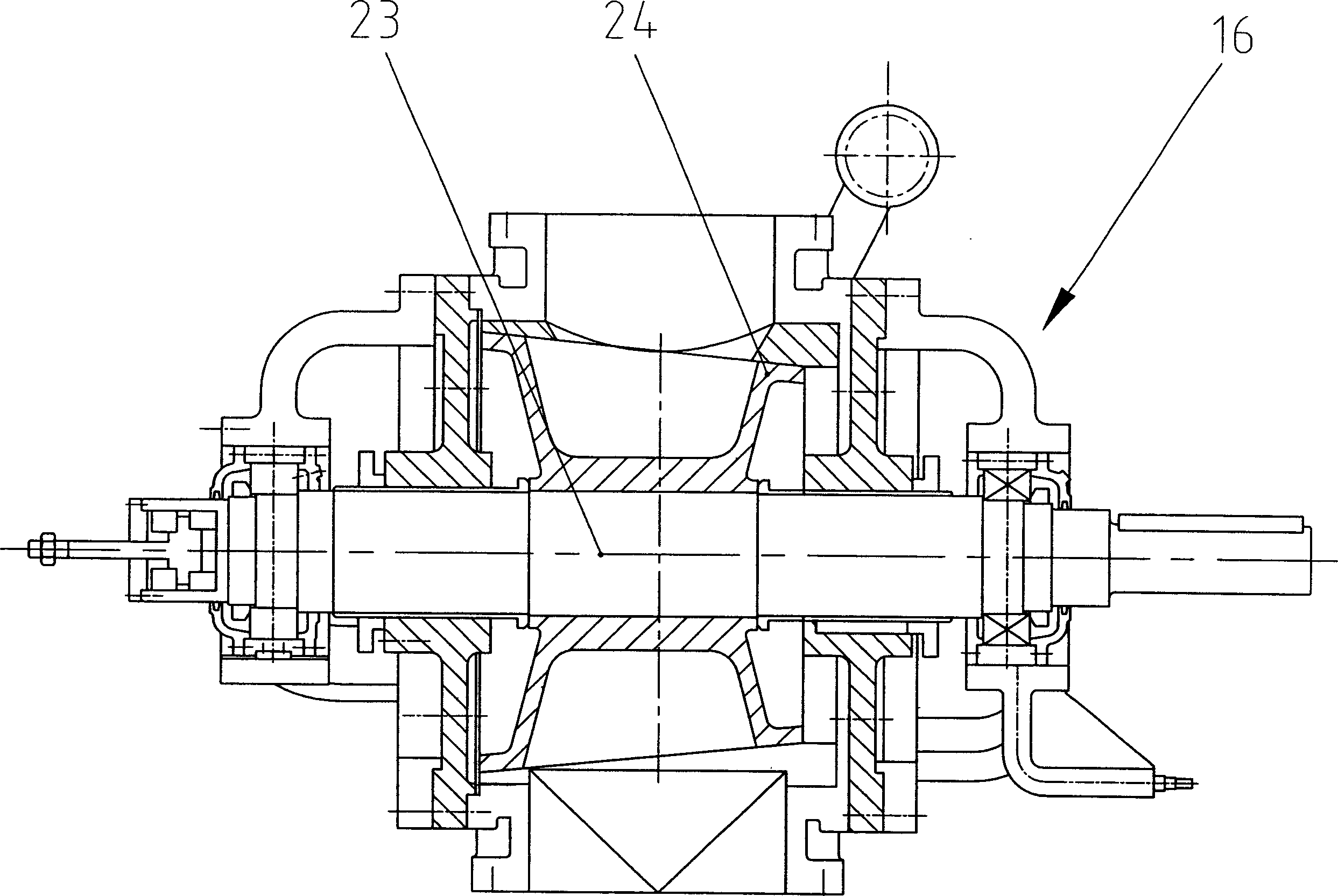

[0063] As mentioned above, since the semi-chemical mechanical pulp of long bast fiber raw materials such as cotton stalk and kenaf has the characteristics of high hardness and many long basts, if an atmospheric refiner is used for refining after continuous cooking, the continuous cooking The final slurry is sprayed first to reduce it to normal pressure, but in this case, the half-cooked slurry is very easy to block the pipeline, so if figure 1 As shown, the continuous cooking method for long bast fiber raw material semi-chemical mechanical pulp provided by the present invention is characterized in that the grid rotor valve 16 is directly used after the second-stage cooking pipe 15 in the continuous cooking process. Such as image 3 As shown, the compartment rotor valve 16 can seal the pressure in the cooking pipe, and is provided with a plurality of compartments 24 which are integrally formed with the rotor 23 and thus can rotate. When the upper compartment is rotated 180 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com