Photoresistive desquamation process and apparatus thereof

A stripping device and photoresist technology, applied in the field of semiconductor manufacturing process and device, can solve the problems of high operating cost, high production cost, low yield, etc., and achieve the effects of short rinsing process time, increase yield, and reduce aluminum erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

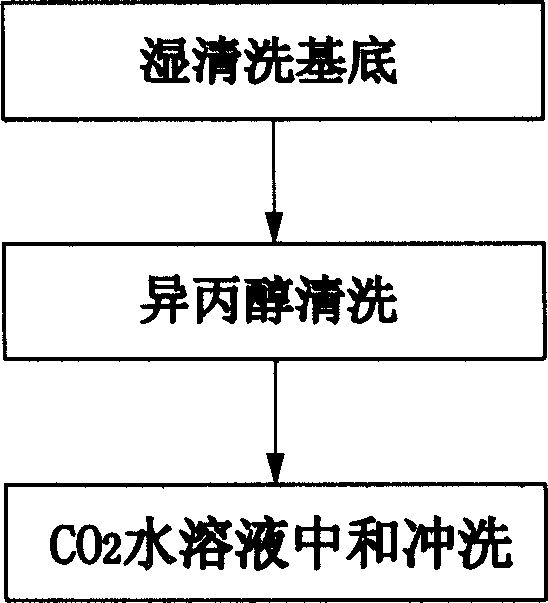

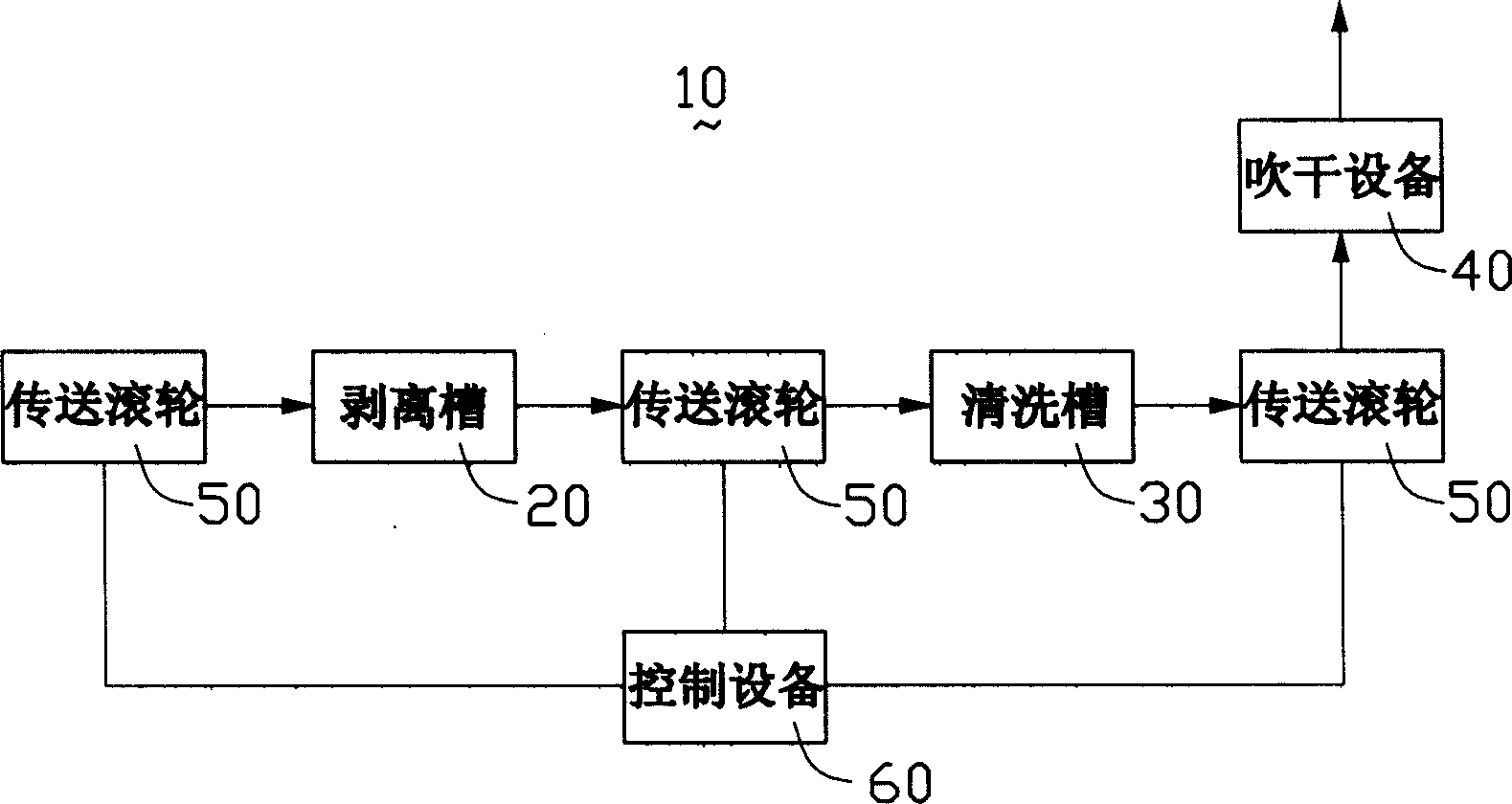

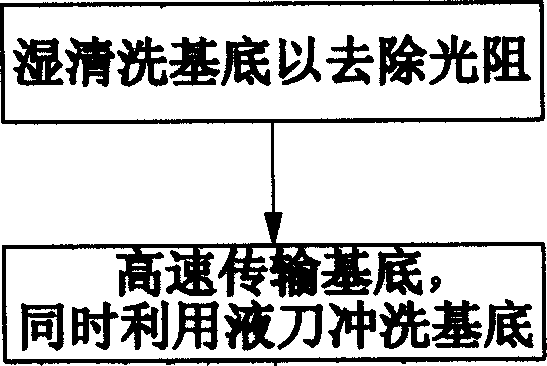

[0024] Such as figure 2 As shown, the photoresist stripping process of the present invention mainly includes two steps: (1) wet-cleaning the substrate; (2) transferring the substrate at high speed while rinsing the substrate with a liquid knife.

[0025] First, the substrate including the photoresist layer to be subjected to the photoresist stripping process is placed in a wet bench, and the photoresist stripping solution is sprayed onto the surface of the substrate. The photoresist stripping solution is an organic solvent, such as N-methylrolidone. The method of spraying the photoresist stripper can be spray coating or spin coating. The spraying method uses a nozzle to evenly spray the photoresist stripping solution onto the surface of the substrate, while the spin coating method puts the photoresist stripping solution on the substrate surface, and then rotates the substrate so that the photoresist stripping solution is evenly distributed on the substrate.

[0026] The pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com