Device for transforming cellulose into levodextron

A levoglucosan and cellulose technology, applied in the field of cellulose-converted levoglucosan equipment, can solve the problems of complex conversion rate, impossibility of large-scale industrial production and utilization, and low cost, so as to reduce production cost and cut materials The method is easy to operate and prevents the effect of low temperature pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

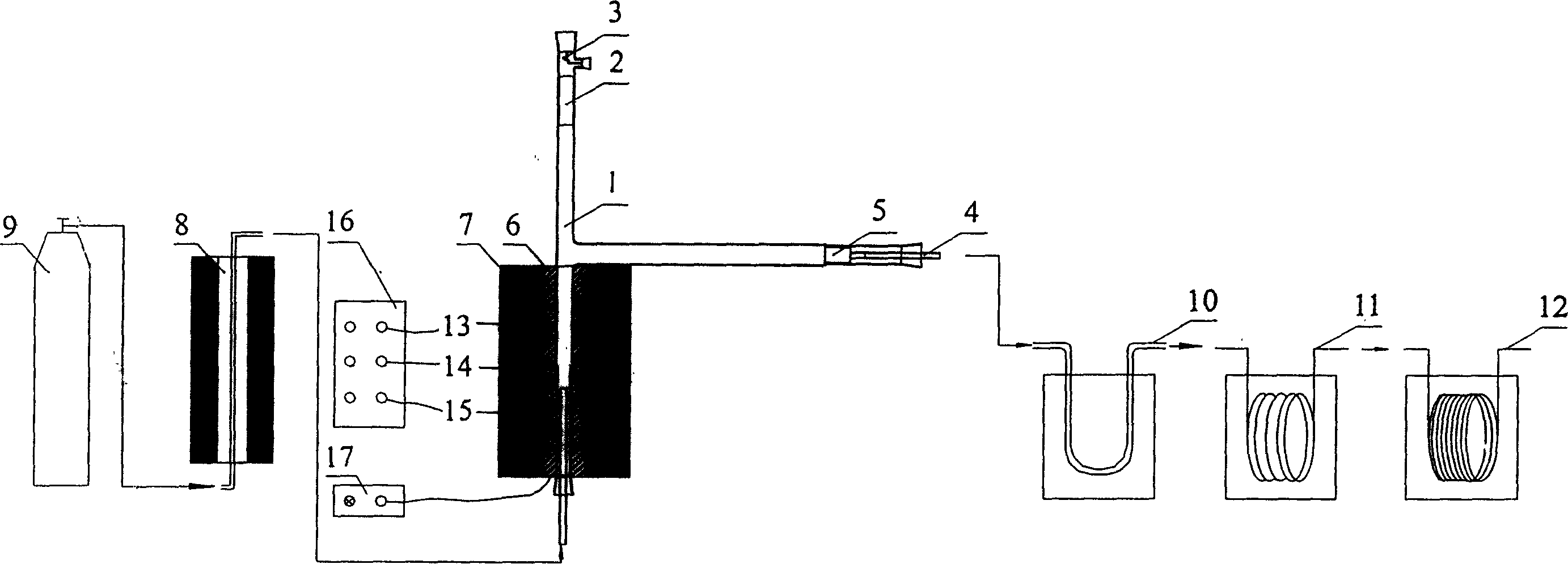

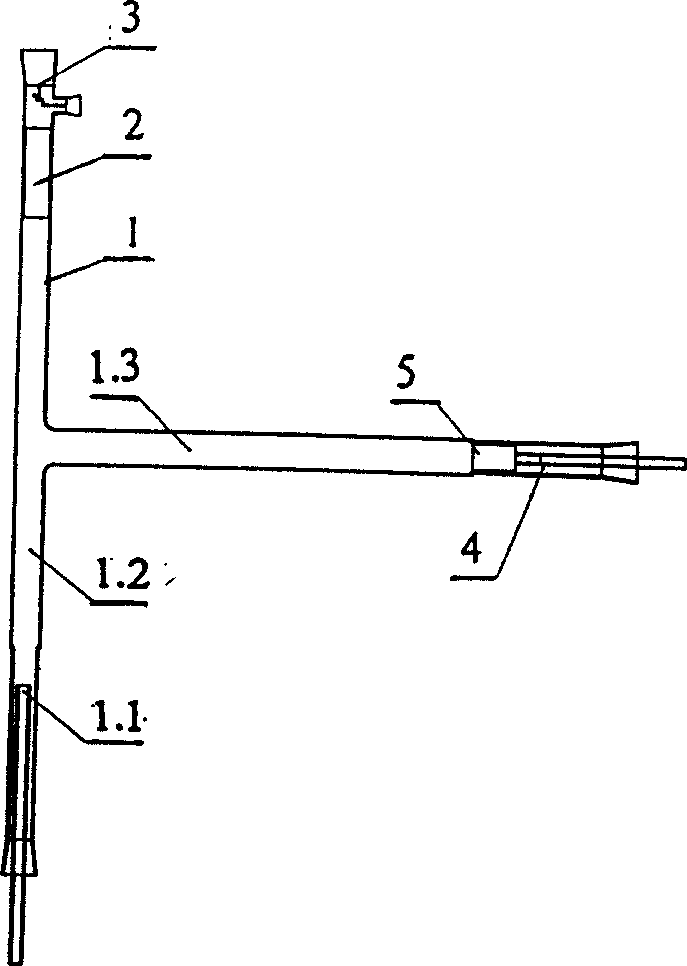

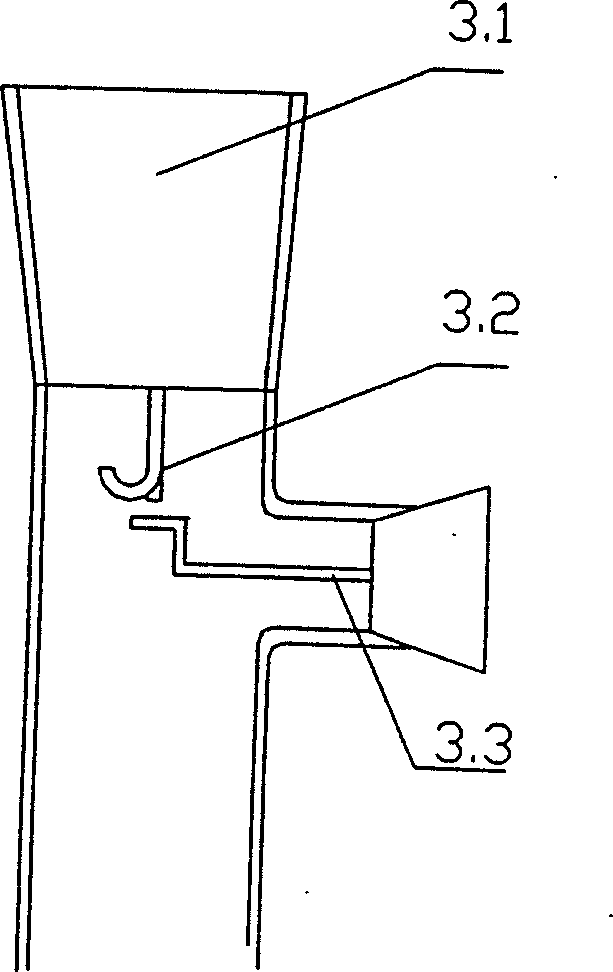

[0021] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a quartz glass tube reactor 1 and a multi-stage condensing device; wherein: the lower port of the quartz glass tube reactor 1 is connected with a nitrogen interface 1.1, and the nitrogen interface 1.1 passes through a fluidized bed preheating device 8 Connect high-purity nitrogen 9, the horizontal branch pipe of the quartz glass tube is equipped with a filter 5, the outlet end of the filter 5 is connected to a multi-stage condensing device in turn, the upper end of the quartz glass tube is equipped with an upper sealing cover 3, and the feeding material of the upper sealing cover 3 There is a hook 3.2 for holding the cylindrical material 2 under the mouth 3.1, a lever 3.3 for the cylindrical material 2 is installed on the side of the quartz glass tube, and a silicon carbon tube 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com