Method for removing lattice defect in pad area of semiconductor device

A lattice defect and pad area technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve not particularly reliable, pad area lattice defects, DRAM reliability effects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

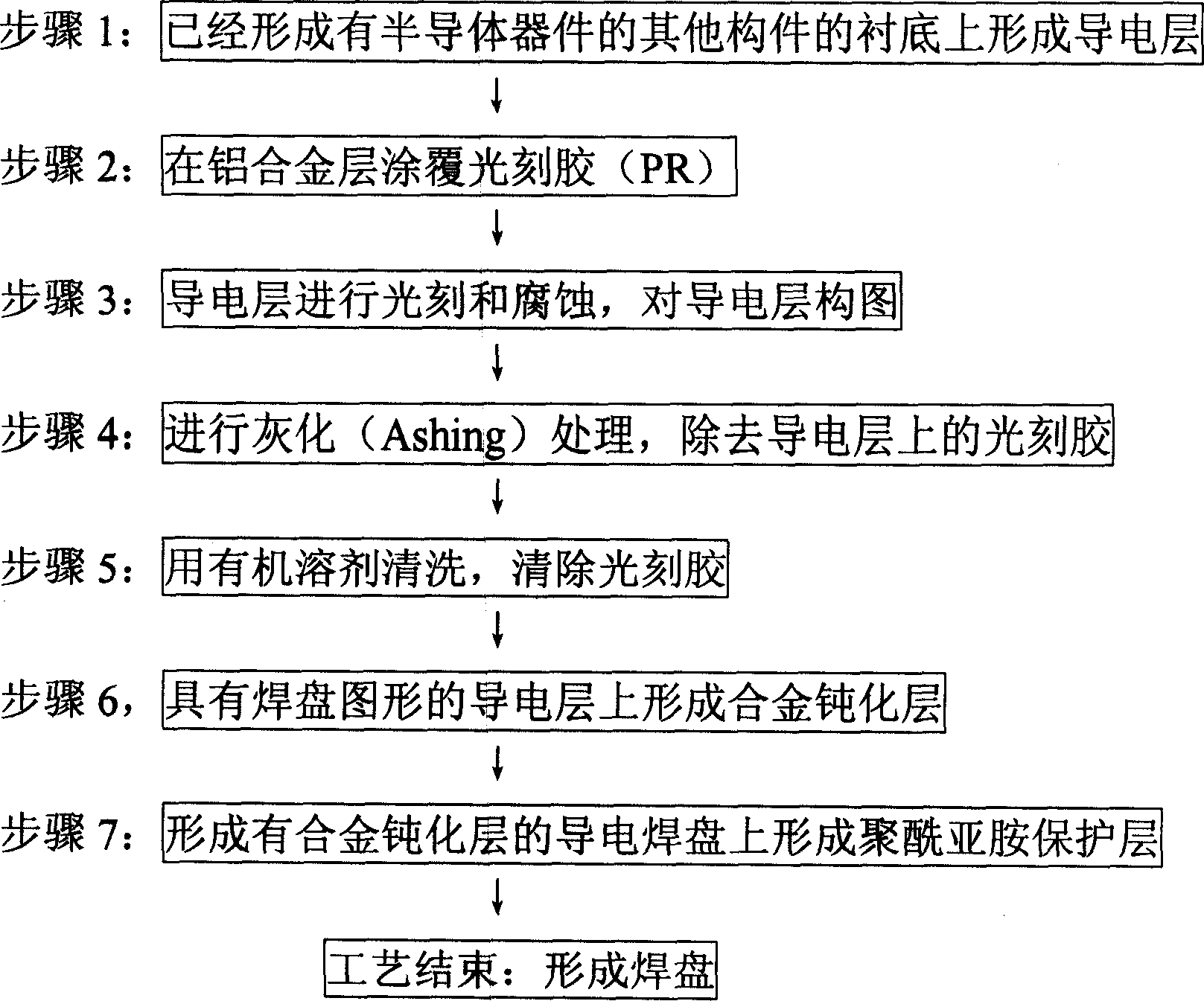

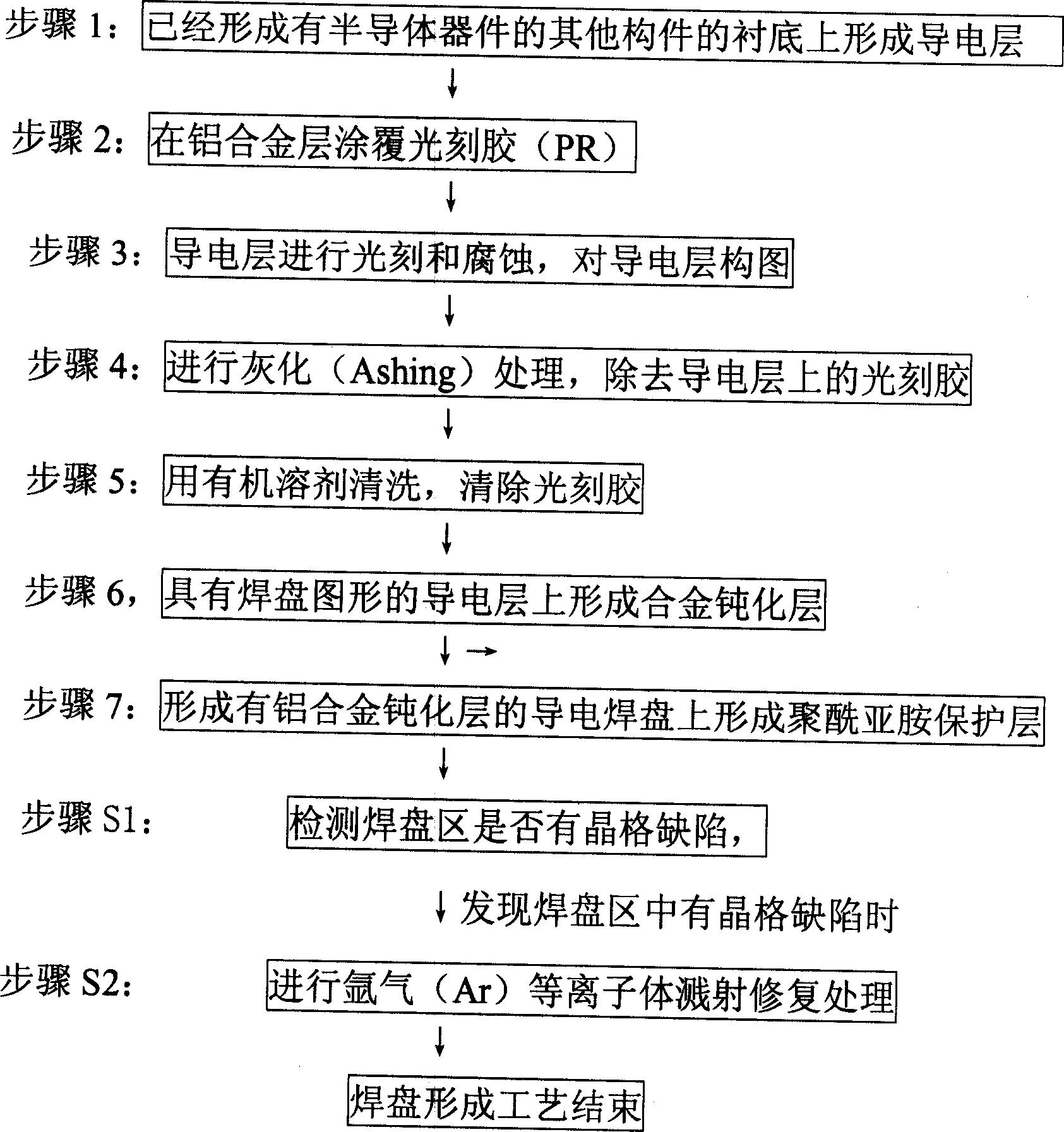

[0014] see below figure 2 A method for removing lattice defects in a pad (PAD) region of a semiconductor device using an argon (Ar) plasma sputtering repair process according to the present invention will be described in detail. figure 2 It is a flow chart of the bonding pad formation process of the semiconductor device according to the present invention.

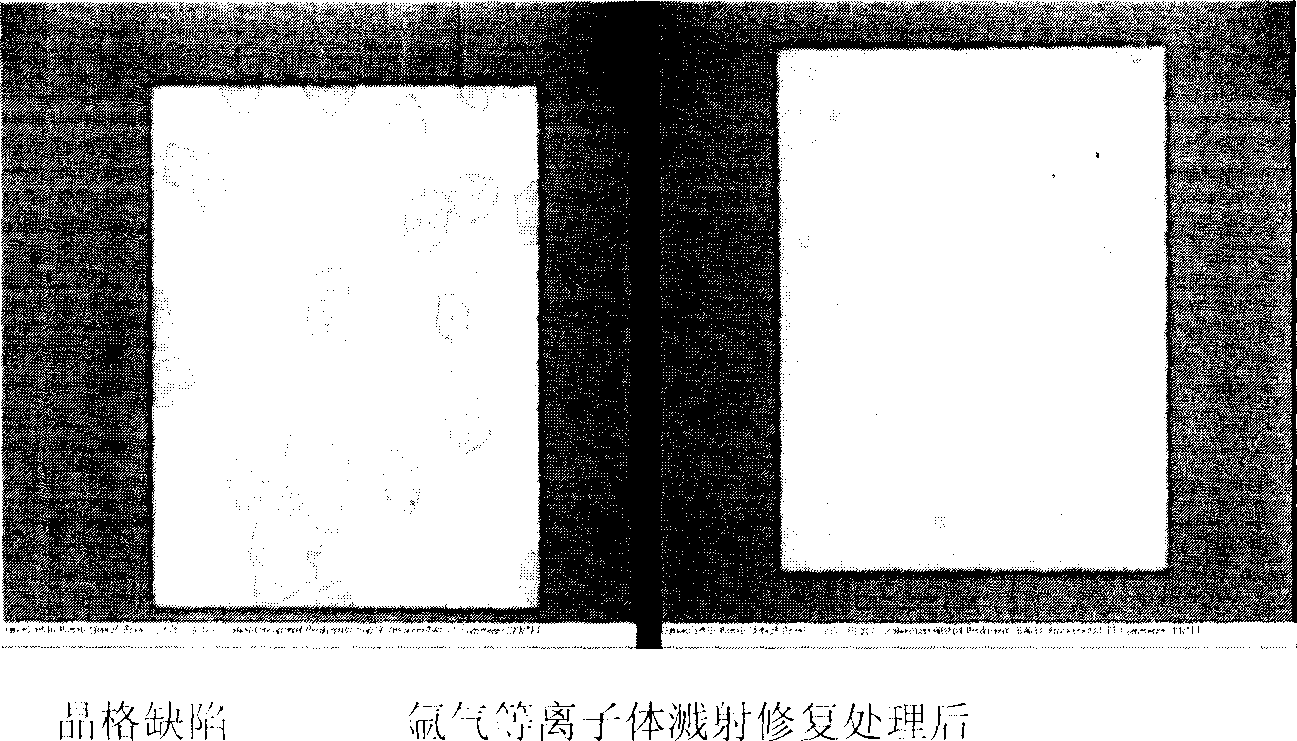

[0015] exist figure 2 The pad formation process flow of the semiconductor device according to the present invention is shown in figure 1 After the step 7 (forming the polyimide protective layer) of the shown bonding pad formation process flow of the existing semiconductor device, an increase is made: step S1, whether there is a lattice defect in the detection pad region; and step S2, when the step When S1 detects that there is a lattice defect in the pad region, argon (Ar) plasma sputtering repair treatment is performed. In step S1, use an optical microscope (OM) to detect whether there is a lattice defect in the pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com