Manufacturing method of semiconductor

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as lower pass rate of DARM products and surface damage of Si substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

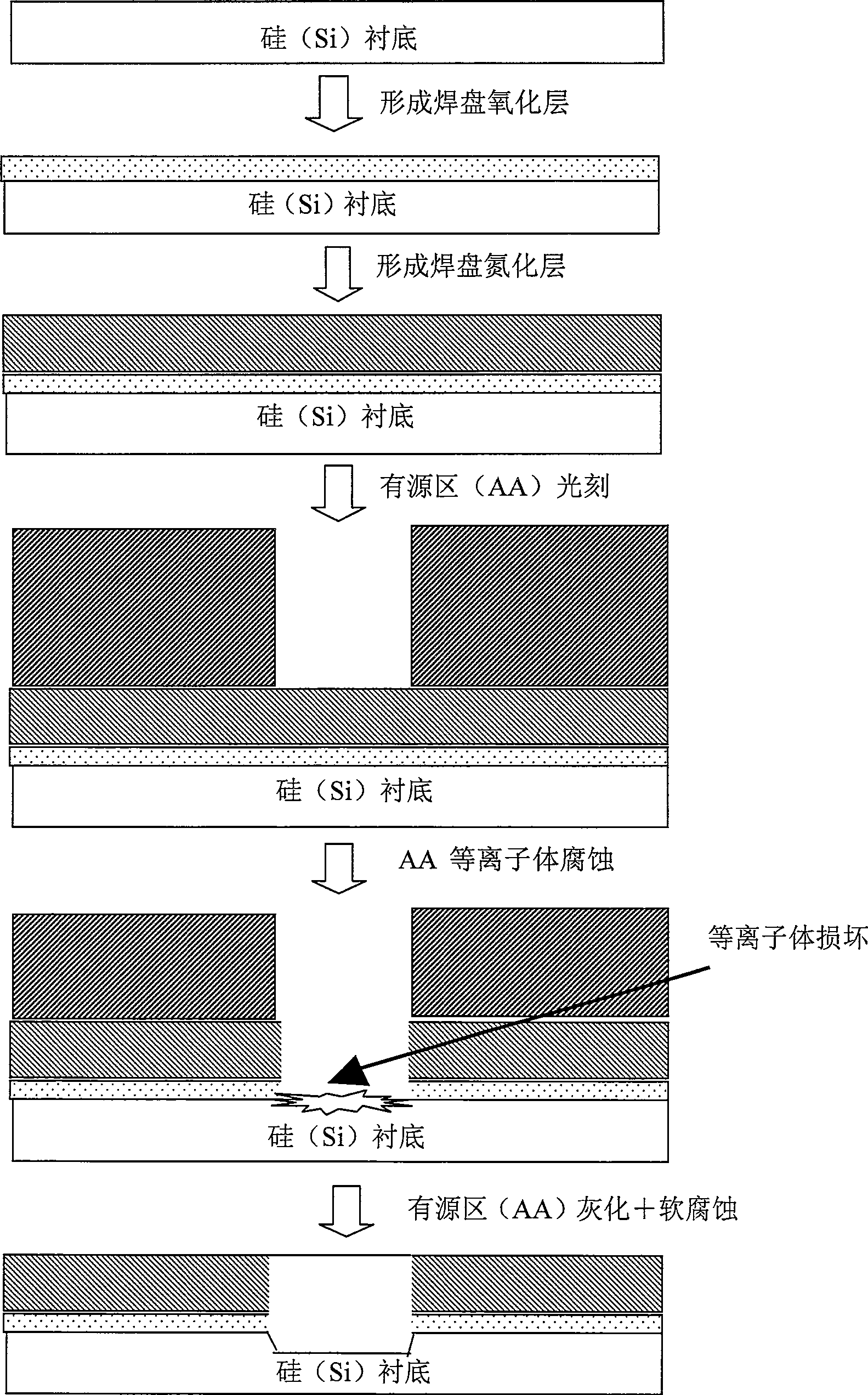

[0016] According to the manufacturing method of semiconductor device of the present invention, comprise the following steps:

[0017] Step 1: grow pad oxide layer (Pad-ox) by diffusion furnace on Si substrate, its thickness is

[0018] Step 2: Then grow silicon nitride (Si 3 N 4 ) (its thickness is ).

[0019] Step 3: Add photoresist (PR) on the insulating film to form the isolation layer, and use a mask with an isolation layer pattern for exposure and development

[0020] Step 4: active area etching (RIE plasma etching);

[0021] Step 5: Additional soft corrosion, soft corrosion is a kind of physical and chemical corrosion, under microwave plasma (frequency 2.45GHz), use CF 4 / O 2 The mixed gas used as an etchant to remove lattice defects caused by plasma damage, CF 4 / O 2 The flow rate ratio of the mixed gas is CF 4 :O 2 =1:(3~5), preferred CF 4 / O 2 The flow rate ratio of the mixed gas is CF 4 :O 2 =1:4.

[0022] Step 6: stripping the photoresist (PR);

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com