Encapsulated platinum-group subnano metal-supported porous titanium-silicon molecular sieve catalyst and its preparation and application

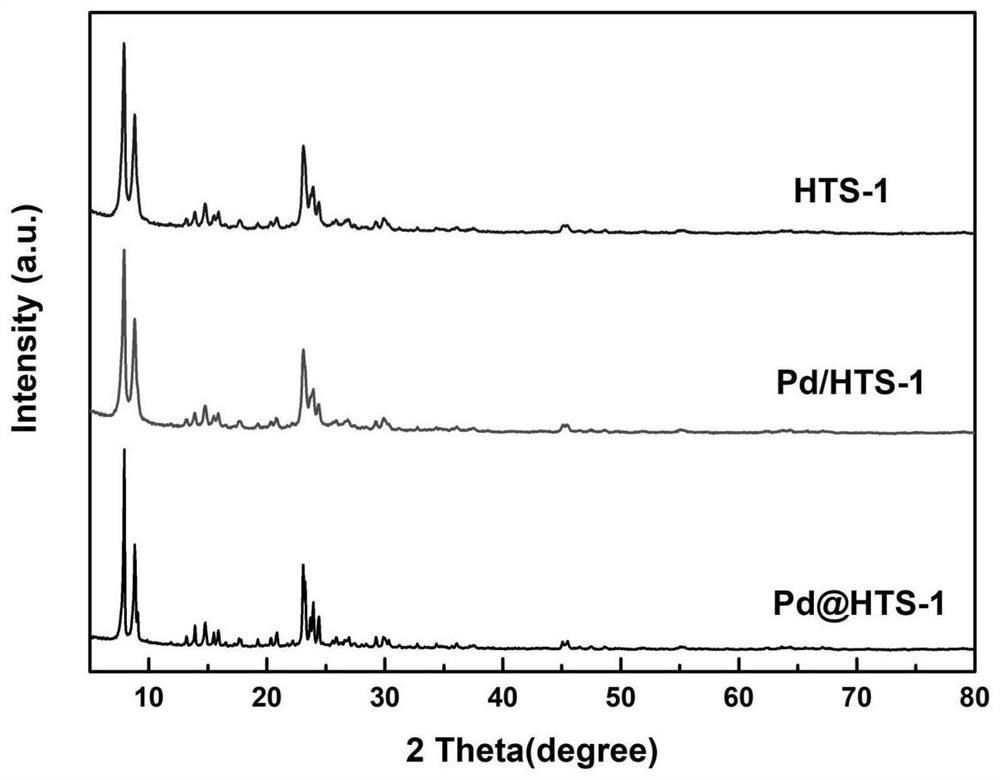

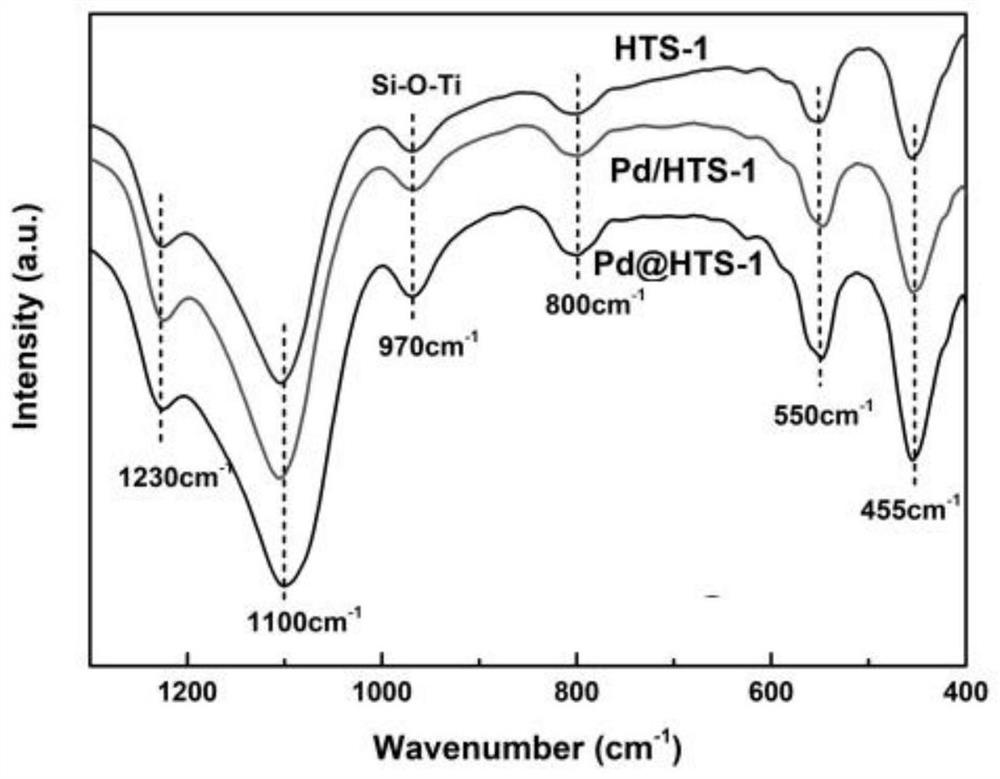

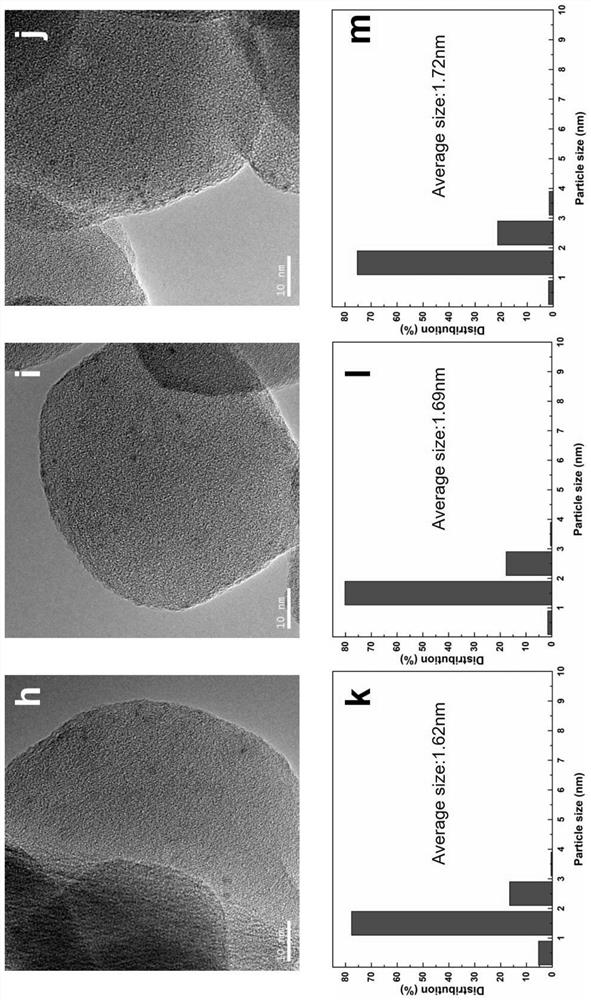

A technology of titanium-silicon molecular sieve and platinum group metals, which is applied in the chemical field, can solve the problems of excessive metal particle size, loss of hydrogenation catalyst, unfavorable metal utilization rate, etc., and achieve high metal utilization rate, improved selectivity, and excellent anti-sintering performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0042] (1) Take 10mL tetrapropylammonium hydroxide (TPAOH) in a 100mL beaker, add 22μL (3-mercaptopropyl)trimethoxysilane (KH590), stir for about 1h, add dropwise 0.36ml Pd concentration under stirring 0.01g / mL of (Pd(NH 3 ) 4 Cl 2 ) solution, open and stir for about 12 hours (liquid a);

[0043] (2) Weigh 0.544g of tetraethyl titanate into a 100mL beaker, add 12mL of ethanol and 2mL of TPAOH and stir for 1h (solution b);

[0044] (3) Slowly add liquid a into liquid b, stir for about 0.5h to obtain liquid c;

[0045] (4) Weigh 10mL of ethanol, 13.2mL of tetraethyl orthosilicate (TEOS), and 1.3mL of hexadecyltrimethoxysilane (HTS) into a 100mL beaker, stir for about 20min to obtain liquid d;

[0046] (5) Quickly add liquid c to liquid d, and stir for about 1 hour;

[0047] (6) Open and stir until a gel is formed, and age for 24 hours;

[0048] (7) Put the gel into a hydrothermal crystallization kettle and seal it, and crystallize at 120°C for 21 days;

[0049] (8) Collec...

Embodiment 4-6

[0059] (1) Take 10mL TPAOH in a 100mL beaker, add 20μL (3-mercaptopropyl)trimethoxysilane, stir for about 1h, add 0.36ml 0.01g / mLH 2 PtCl 6 Solution, open and stir for about 12 hours (liquid a);

[0060] (2) Weigh 0.544g of tetraethyl titanate into a 100mL beaker, add 12mL of ethanol and 2mL of TPAOH and stir for 1h (solution b);

[0061] (3) Slowly add liquid a into liquid b, stir for about 0.5h to obtain liquid c;

[0062] (4) Weigh 10mL of ethanol, 13.2mL of TEOS, and 1.5mL of HTS into a 100mL beaker, and stir for about 20min (solution d);

[0063] (5) Quickly add liquid c to liquid d, and stir for about 1 hour;

[0064] (6) Open and stir until a gel is formed, and age for about 12 hours;

[0065] (7) Put it into a crystallization kettle, and crystallize for 7 days at 120°C;

[0066] (8) filter, wash with water, and dry at 110°C for 3 hours;

[0067] (9) Oxidation: 500°C, Air, 4h, to get Pt@HTS-1;

[0068] (10) Reduction: 400°C, H 2 , 2h, get Pt@HTS-1-OR;

[0069] ...

Embodiment 7-9

[0074] (1) Take 10mL TPAOH in a 100mL beaker, add 20μL (3-mercaptopropyl)trimethoxysilane, stir for about 1h, add 0.36ml 0.01g / mL HAuCl dropwise under stirring 4 Solution, open and stir for about 12 hours (liquid a);

[0075] (2) Weigh 0.544g of tetraethyl titanate into a 100mL beaker, add 12mL of ethanol and 2mL of TPAOH and stir for 1h (solution b);

[0076] (3) Slowly add liquid a into liquid b, stir for about 0.5h to obtain liquid c;

[0077] (4) Weigh 10mL of ethanol, 13.2mL of TEOS, and 1.5mL of HTS into a 100mL beaker, and stir for about 20min (solution d);

[0078] (5) Quickly add liquid c to liquid d, and stir for about 1 hour;

[0079] (6) Open and stir until a gel is formed, and age for about 12 hours;

[0080] (7) Put it into a crystallization kettle, and crystallize for 7 days at 120°C;

[0081] (8) filter, wash with water, and dry at 110°C for 3 hours;

[0082] (9) Oxidation: 500°C, Air, 4h, to get Au@HTS-1;

[0083] (10) Reduction: 400°C, H 2 , 2h, get Au@H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com