End effector assembly for supporting substrates

An end effector and support technology, which is used in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., and can solve problems such as fracture, particle substrate damage, and pollution treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

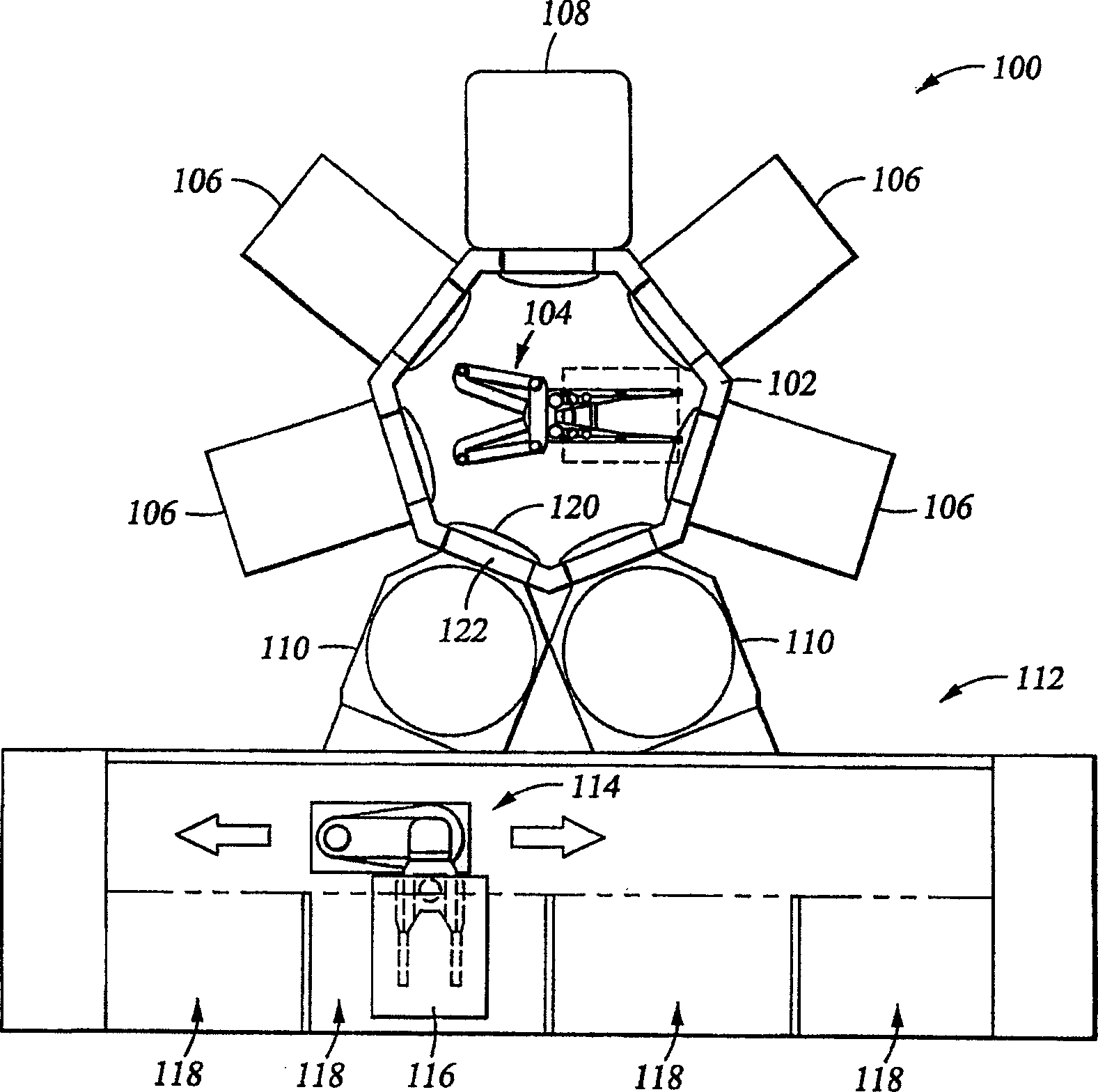

[0074] figure 1 A schematic layout of cluster tool 100 is shown. The cluster tool 100 generally includes a delivery chamber 102 having a first delivery robot 104 disposed therein. The transport chamber 102 is surrounded by a plurality of processing chambers 106 , a thermal processing chamber 108 and at least one load lock chamber 110 . The load lock chamber 110 is coupled between the transfer chamber 102 and a factory interface 112, and two of the load lock chambers 110 are indicated at figure 1 middle. One clustering tool that may be employed to benefit from the present invention is manufactured by AKT Corporation, a company owned by Applied Materials, Inc. of Santa Clara, California, USA.

[0075] The fab interface 112 generally includes a second transfer robot 114 that transfers substrates 116 between the load lock chambers 110 and a plurality of wafer storage cassettes 118 coupled to or disposed within the fab interface 112 . The second delivery robot 114 can be made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com