Slot milling grinding wheel of cubic boron nitride and manufacturing method

A technology of cubic boron nitride and manufacturing methods, applied in the direction of manufacturing tools, bonded grinding wheels, abrasives, etc., can solve problems such as economic difficulties, high compressor noise, and low processing efficiency of abrasive tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

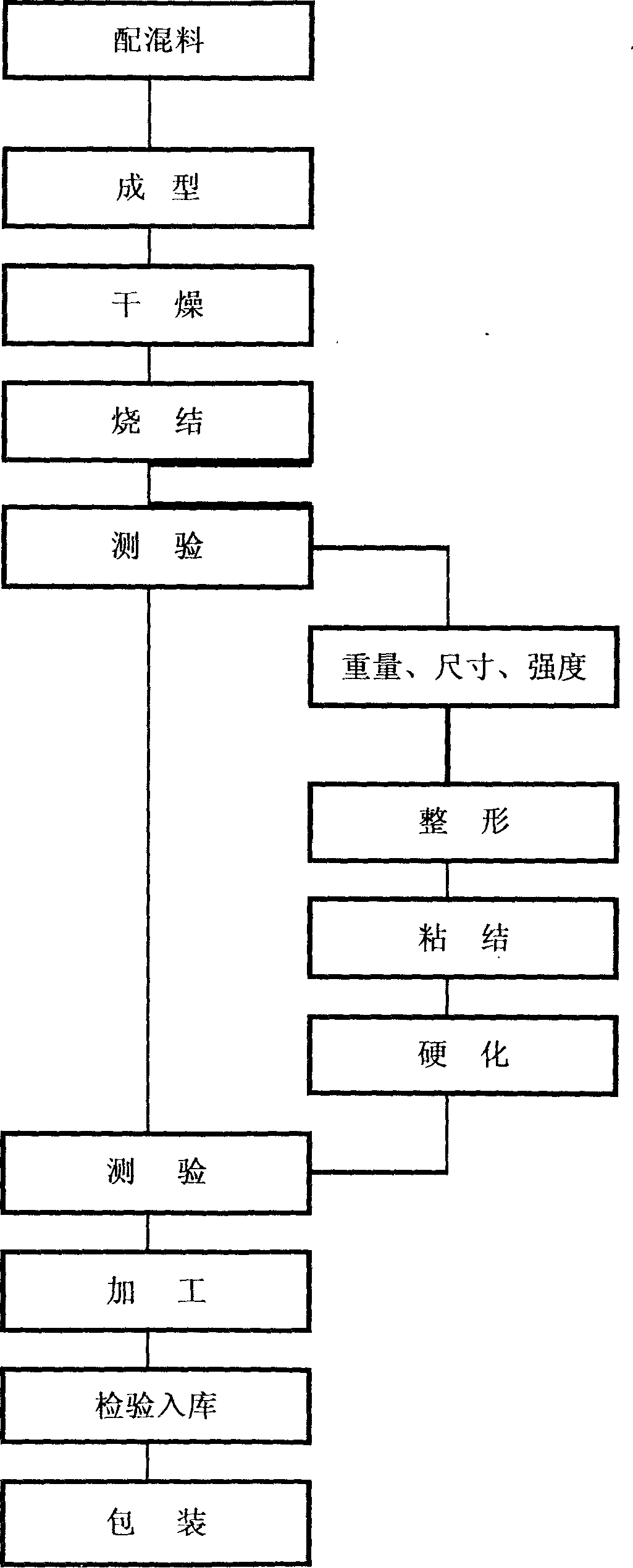

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

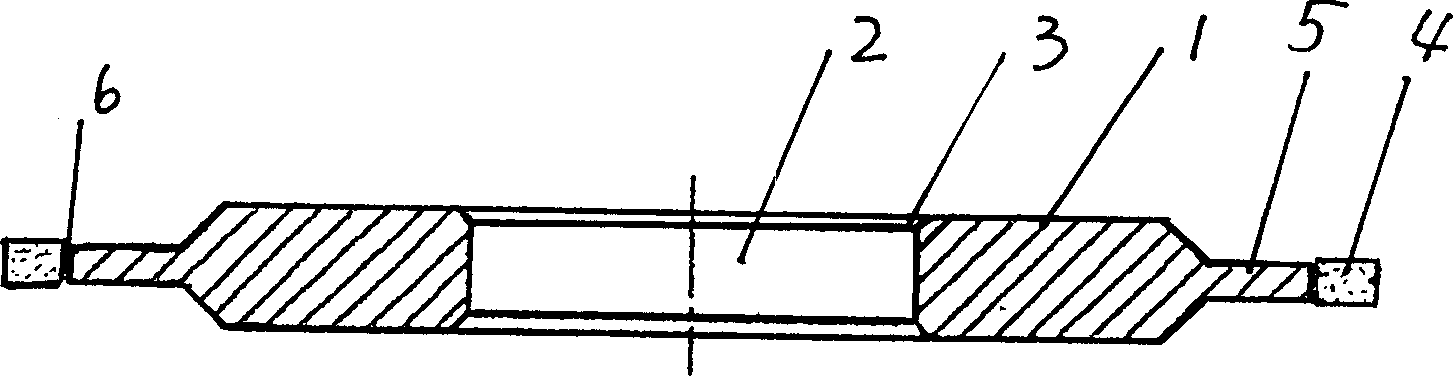

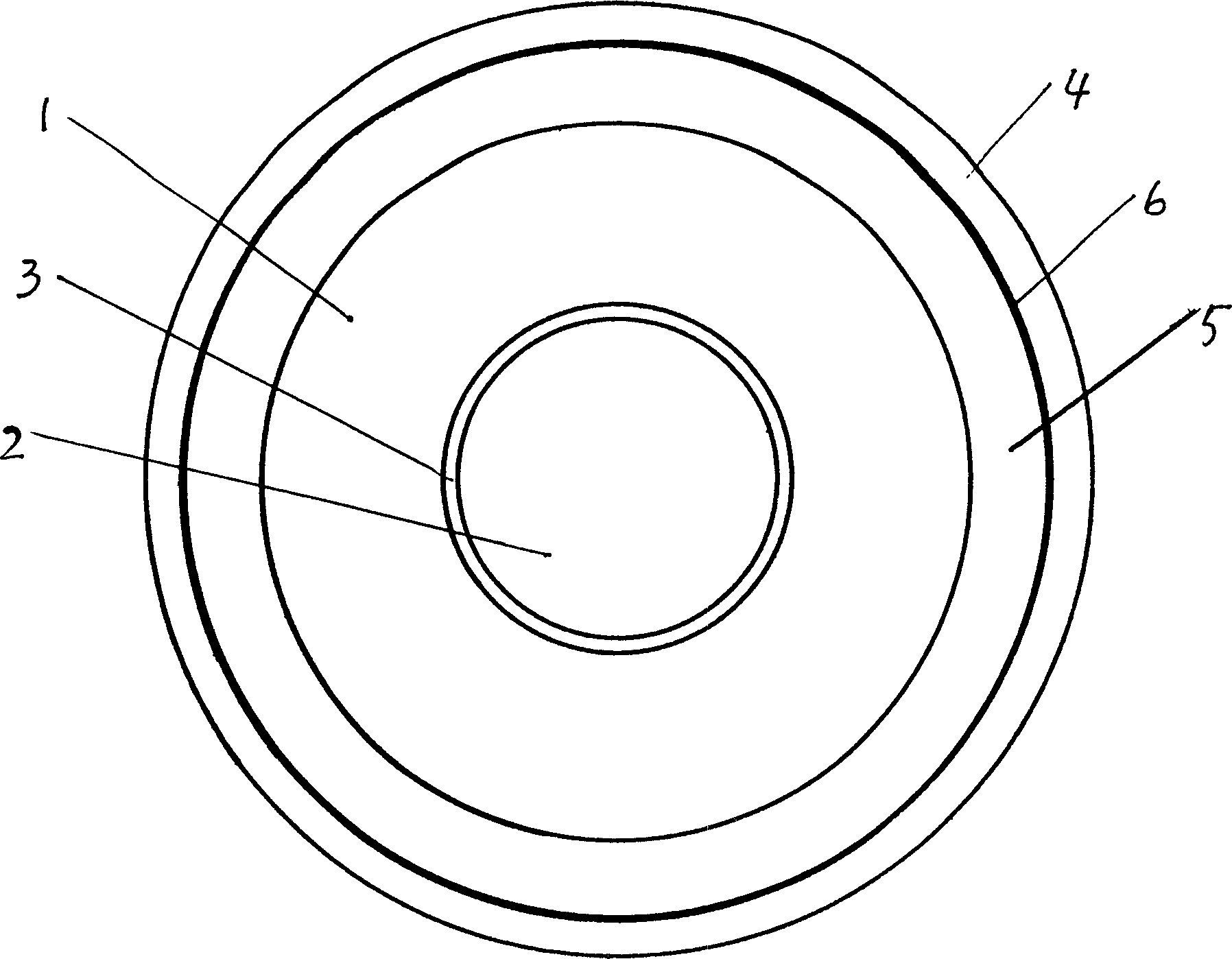

[0008] Depend on figure 1 Given, the grinding wheel of the present invention has a mounting hole 2 in the center of the grinding wheel base 1, and the upper and lower ends of the mounting hole are concentric with the mounting hole 2 to have a card slot 3. Cubic boron nitride grinding surface layer 4 is fixed on the periphery through bonding layer 6 .

[0009] The grinding wheel substrate 1 is a hollow metal disc body, and cubic boron nitride is the so-called super-grinding CBN material on the market. The size of the substrate can be made into a series of products as required.

[0010] The diameter of the grinding wheel is generally 208-4000mm; the thickness of the base is generally 12.5-30mm; the diameter of the internal fixing hole is generally 32-203mm; the width of the grinding wheel is generally 6mm; the height of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com