Magnetic suspension balance apron spray-seam gas seal plenum chamber type air cushion train

An air-cushion train and magnetic levitation technology, which is applied to motor vehicles and road vehicles, can solve the problems of small load, high noise of jet engines, and difficult noise pollution, and achieve the effect of large carrying capacity, high air pressure and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

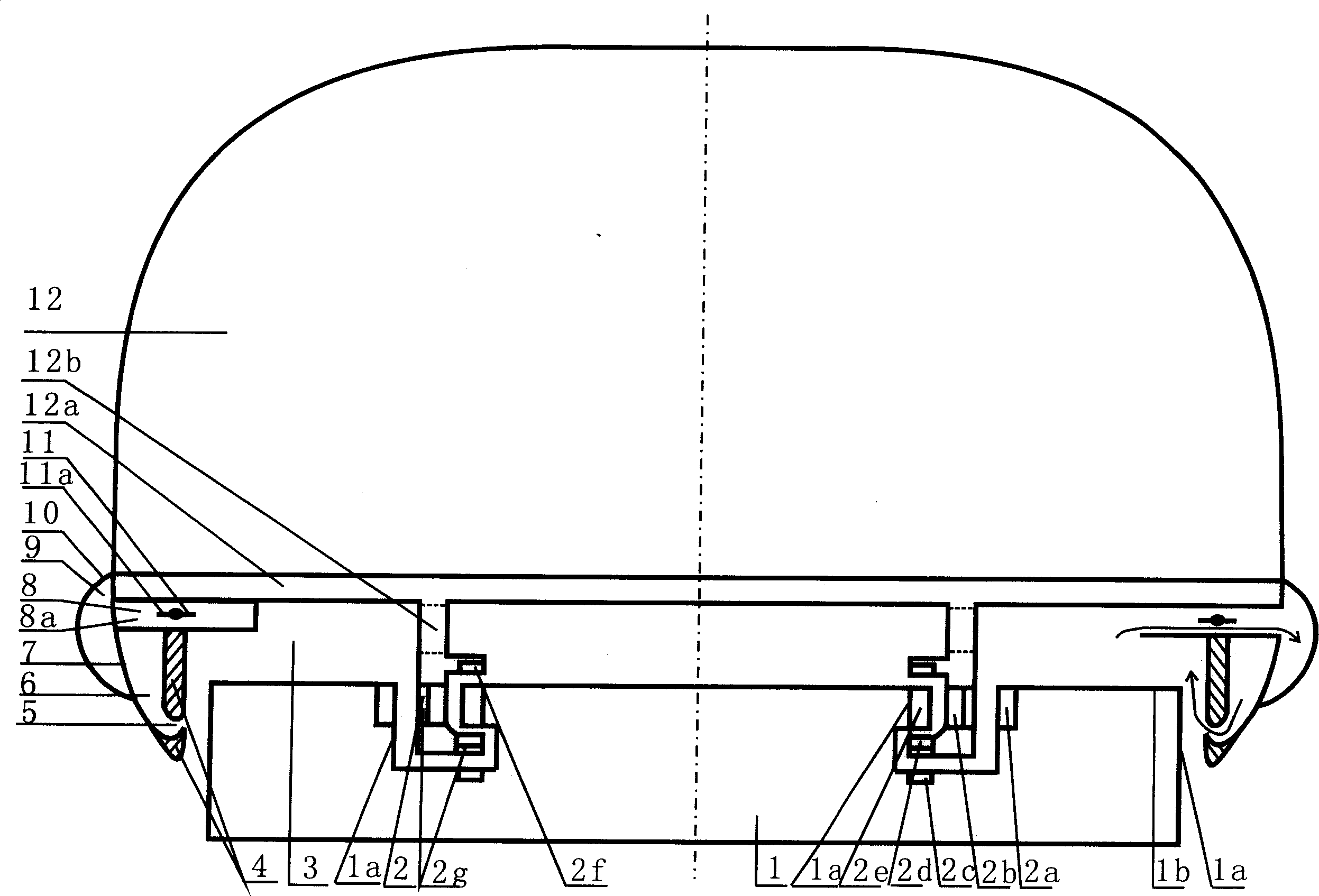

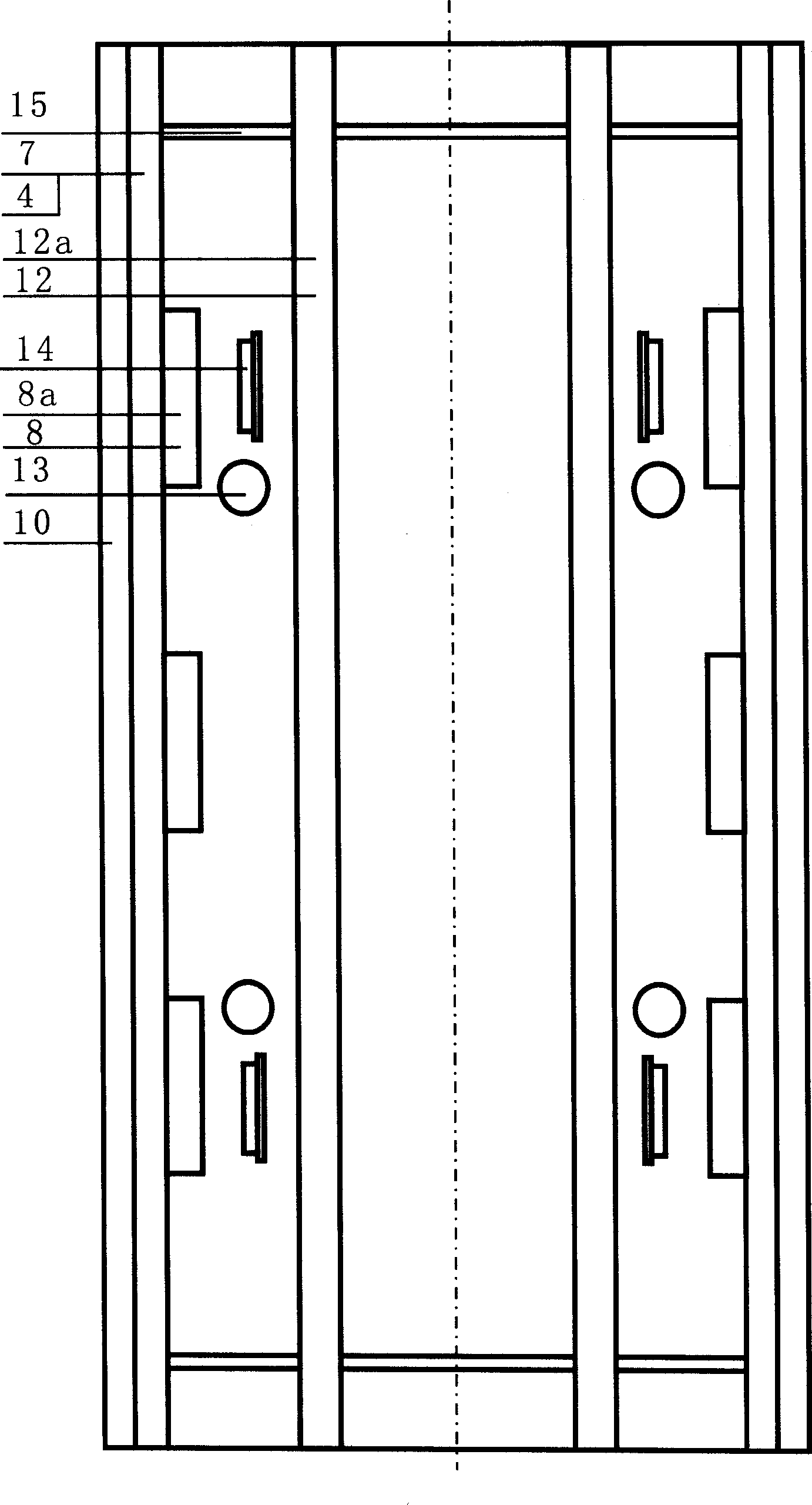

[0030] Example 1: Reference figure 1 , figure 2 , a magnetic suspension balance apron spray seam air-sealed pressurized chamber type air-cushion train, including a car body 12, an air supply device and a road 1; a suspension frame 12a is arranged at the bottom of the car body, and an apron 4 is arranged at the lower part of the outer side of the car body suspension frame 12a, The apron 4 is located on the sides of the road side walls 1a on both sides of the road 1, and the lower end of the apron 4 is lower than the road surface 1b; the air supply pipe wall 7 of the air supply device is connected with the vehicle body suspension frame 12a and the apron 4 to form an air supply pipe 6 of the air supply device , the apron 4 and the road surface 1b and the bottom of the vehicle body in the apron form a pressurized chamber 3 . The apron 4 is provided with an apron wall spray slot 5 that communicates with the air supply pipe 6 of the pressurized chamber 3. The apron wall spray slot...

Embodiment 2

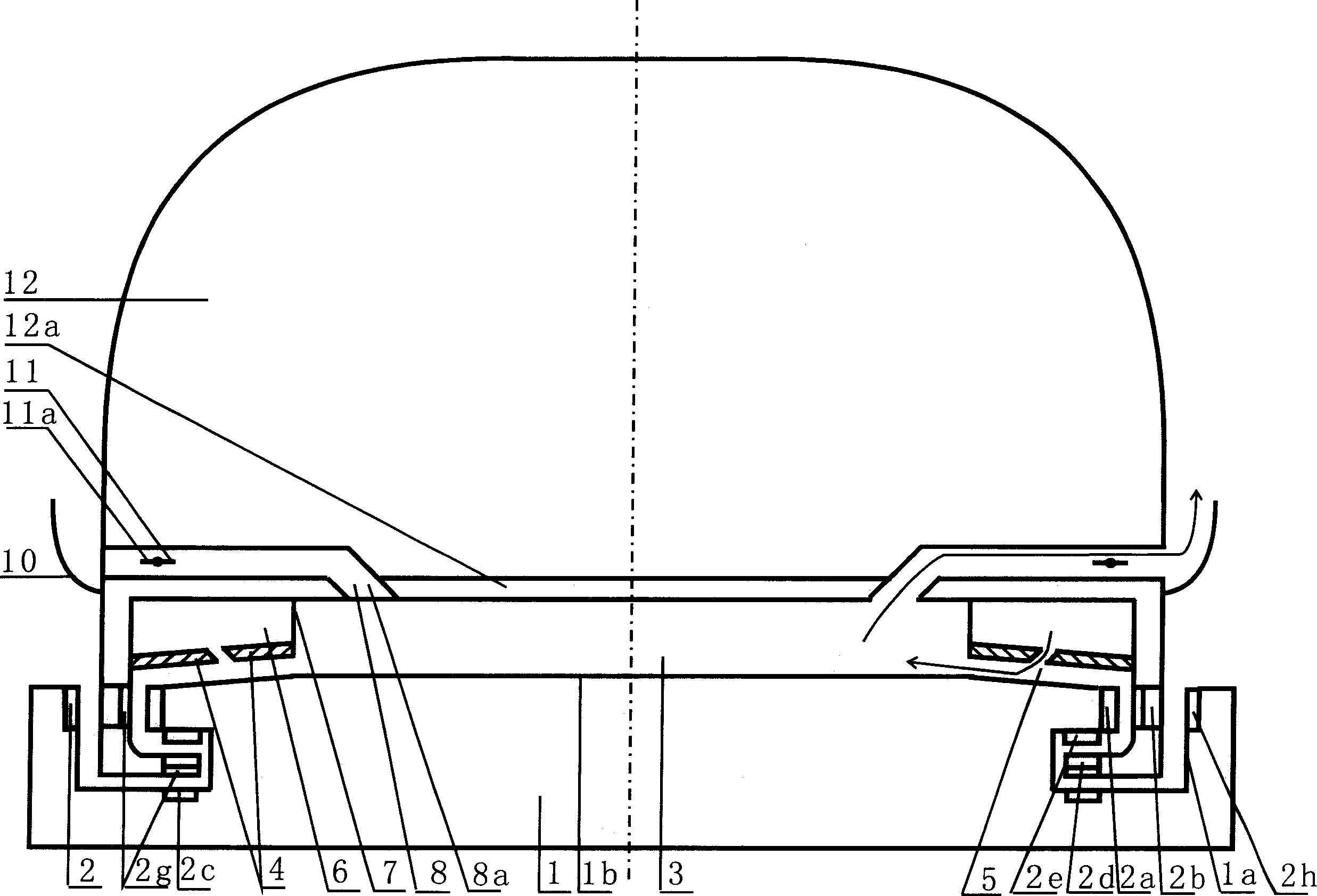

[0039] Example 2: Reference image 3 , Figure 4 , a magnetic suspension balance apron spray seam air-sealed pressurized chamber type air-cushion train, including a car body 12, an air supply device and a road 1. An apron 4 is provided on the inner lower part of the suspension frame 12a at the bottom of the vehicle body. The apron 4 is on the road surface 1b and is parallel to the road surface 1b below the apron 4; Pipe 6, apron 4, road surface 1b and the bottom of the vehicle body in the apron form a pressurized chamber 3, and the apron 4 is provided with an apron wall spray slot 5 that communicates with the pressurized chamber 3 and the air supply pipeline 6, and the air supply pipeline 6 The pressurized gas in the apron is injected into the pressurized chamber 3 through the apron wall nozzle 5; the vehicle body 12 is provided with an exhaust pipe 8a on both sides, one end of the exhaust pipe 8a is opened in the pressurized chamber 3, and the exhaust pipe 8a is provided wit...

Embodiment 3

[0044] Example 3: Reference Figure 5 , Image 6 , a magnetic suspension balance apron spray seam air-sealed pressurized chamber type air-cushion train, including a car body 12, an air supply device and a road 1. The cross section of the road 1 is concave, and the apron 4 is directly formed by the car body 12 on both sides of the car body 12. The apron 4 is on the road surface 1b and parallel to the road surface 1b below the apron 4; the car body 12 is provided with an air supply Pipe 6, apron 4, road surface 1b and the bottom of the vehicle body in the apron form a pressurized chamber 3, and the apron 4 is provided with an apron wall spray slot 5 that communicates with the pressurized chamber 3 and the air supply pipeline 6, and the air supply pipeline 6 The pressurized gas in the apron wall is sprayed into the pressurized chamber 3 through the apron wall jet slot 5; the spaced exhaust slot 8b between the apron wall jet slot 5 is used as the exhaust port 8, and one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com