Method and device for welding thermoplastic material shaped parts, particularly for contour-welding three-dimensional shaped parts

A technology for thermoplastics and molded parts, which is applied in the field of welded and molded thermoplastic molded parts, especially contour welded three-dimensional molded parts and devices, which can solve problems such as industrial application obstacles and process window narrowing, and achieve tolerance compensation, The effect of expanding the process window and reducing the bonding gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

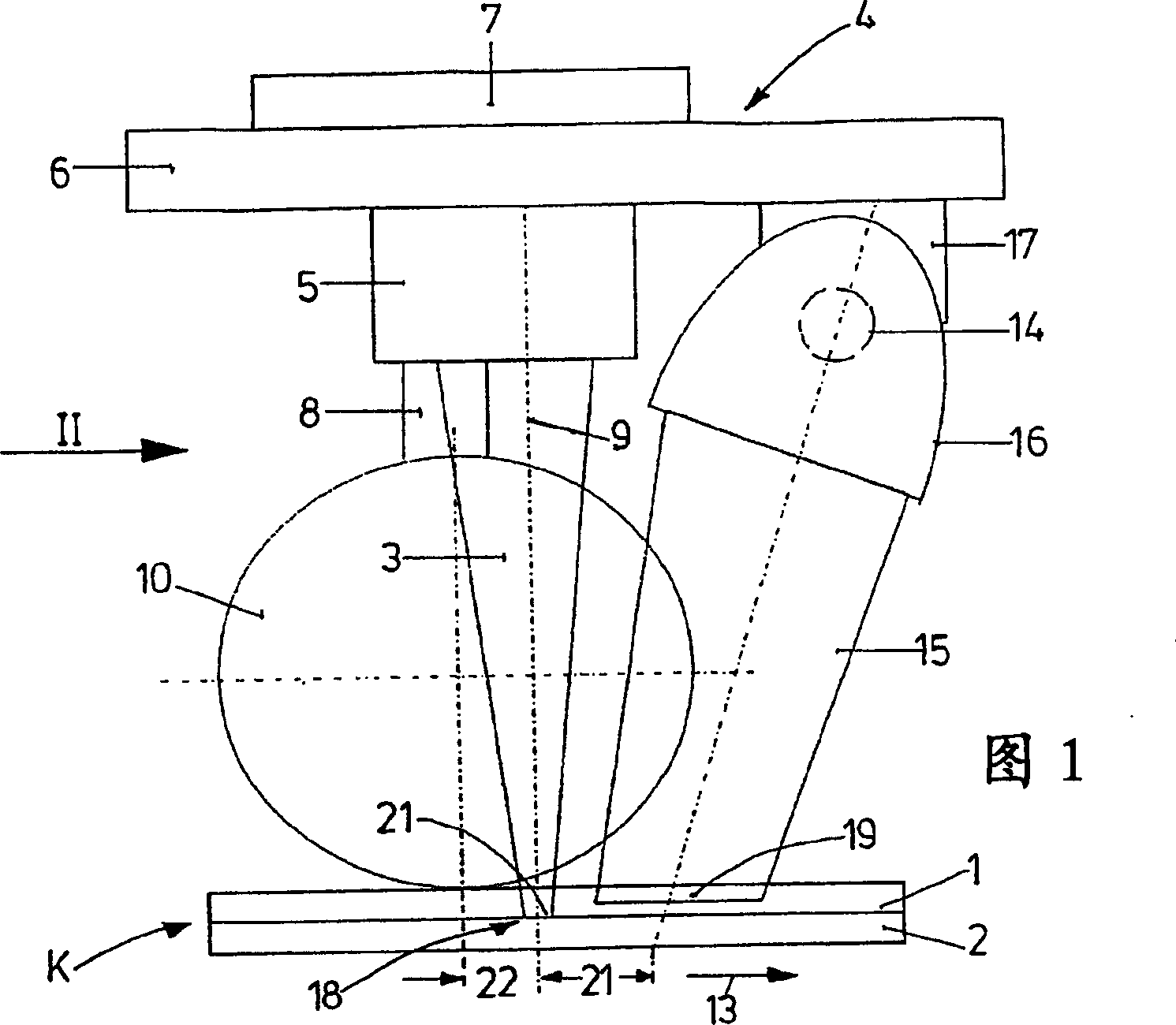

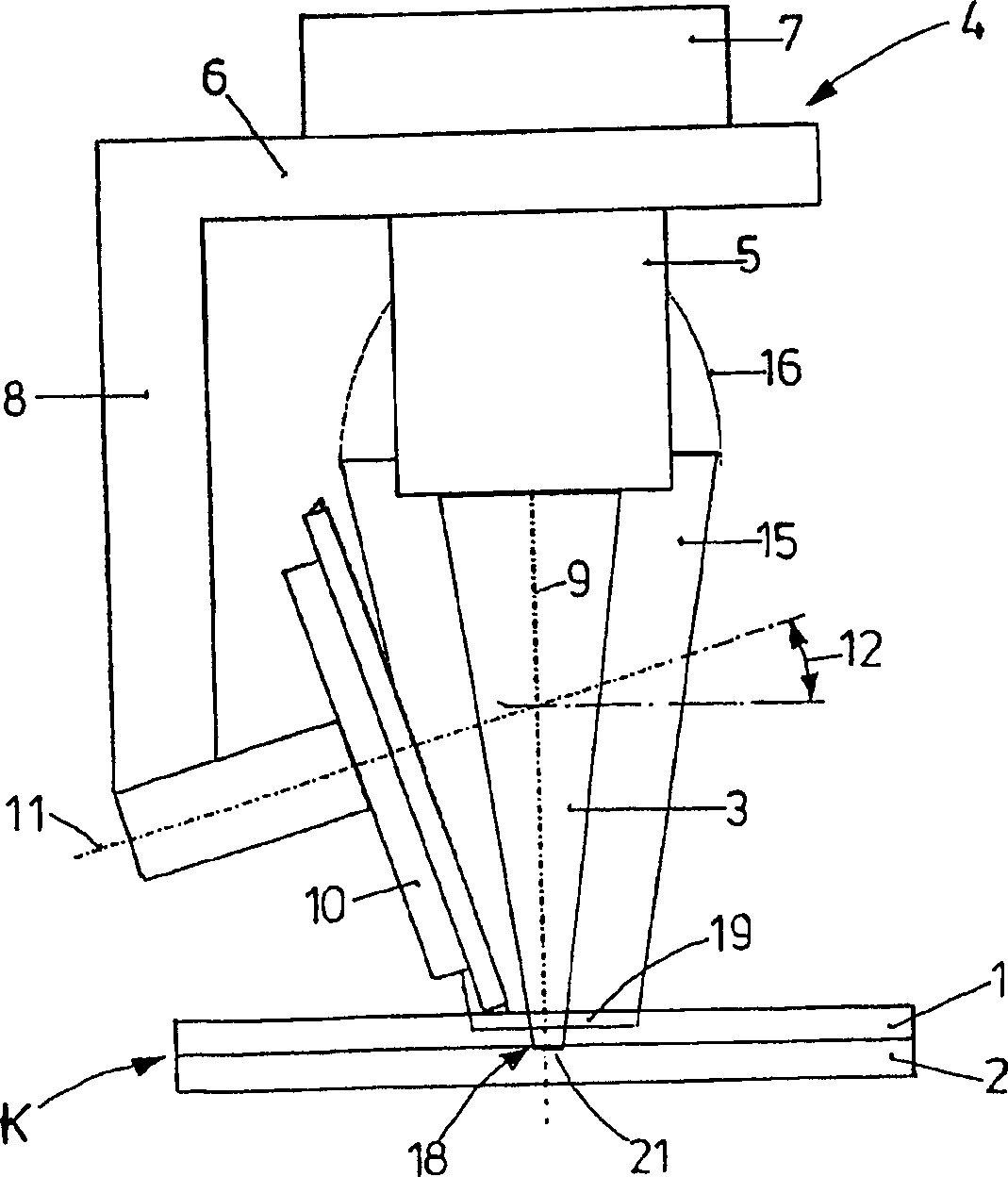

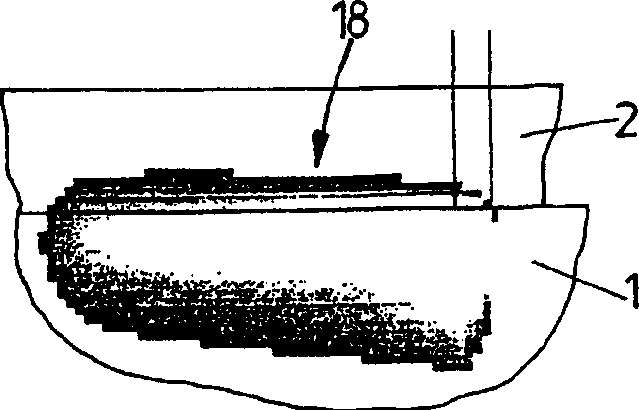

[0027] 1 and 2 show the edge profile K of two joined parts 1 , 2 to be welded. The two parts are joined together by laser irradiation, while the upper joining part 1 must transmit the laser welding beam 3 as much as possible, and the lower joining part 2 must absorb the laser welding beam 3 as much as possible. The rest of the laser irradiation welding is well known and needs no further introduction.

[0028] The laser welding beam 3 is guided from a stationary laser beam source to a focusing optics 5 via a fiber optics system via the processing head, indicated as a whole by 4 . For clarity, the laser source and fiber optics are omitted from the figure. The focusing optics 5 are located on a frame 6 of the processing head 4, which is flange-mounted via an adapter plate 7 with a force-measuring cell, eg on the manipulator arm of an industrial robot.

[0029] The clamping roller 10 is placed near the optical axis 9 of the laser welding beam 3 by means of a bracket 8; joints 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com