Adhesive material and adhesive preparation

A technology of adhesive and adhesive layer, applied in surgical adhesives, medical science, surgery, etc., can solve the problem of changing peelability and achieve good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0104] Embodiment 1-12, comparative example 1-5

[0105] Each of the compositions of Tables 1 to 4 was dissolved in toluene to obtain a coating solution having a solute concentration of 35%. This solution was coated on a silicone release-treated polyethylene terephthalate (PET) liner so that the coating thickness after drying was 120 μm. This liner was dried in a hot air circulating oven at 70° C. for 2 minutes, at 80° C. for 2 minutes, and at 95° C. for 3 minutes to obtain an adhesive layer. 2 μm thick PET film and PET nonwoven fabric (12 g / m 2 ) are adhered to each other to form a carrier, and the non-woven fabric surface of the carrier is laminated on the adhesive layer. The laminate was aged at room temperature for 2 days to obtain adhesive sheets of Examples 1-12 of the present invention and Comparative Examples 1-5.

[0106] For the measurement of apparent viscosity, a sample containing only an adhesive layer without laminating the above-mentioned carrier was recovere...

experiment Embodiment 1

[0141] Experimental Example 1 (Measurement of Apparent Viscosity and Measurement of Adhesive Force)

[0142] The apparent viscosity and adhesive force of the adhesive materials of Examples 1-12 and Comparative Examples 1-5 were measured as follows. The results are shown in Table 5.

[0143]

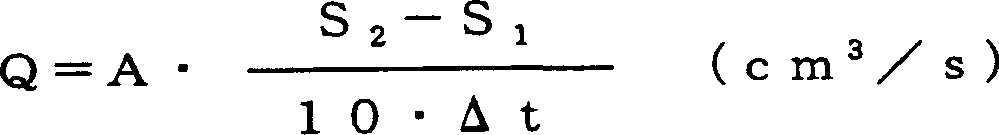

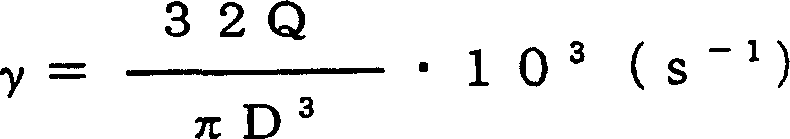

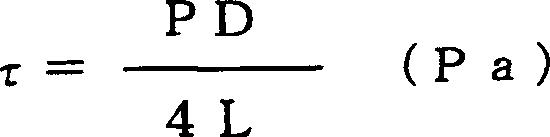

[0144] The above sample was measured according to JIS K7210 using a flow tester CFT-500C (manufactured by Shimadzu Corporation) under the following conditions, and the values were calculated by the following formula. The sample density used is 1.0g / cm 2 .

[0145] [Measurement conditions]

[0146] Sample temperature: 30°C

[0147] Cylinder pressure: 30.0kgf / cm 2

[0148] Die used: L: 10.00mm, D: 1.00mm

[0149] Preheating time: 300s

[0150] Apparent shear stress: 7.36×10 5 dyn / cm 2

[0151] Measurement start position S 1 : 3mm

[0152] Measurement end position S 2 : 7mm

[0153] [Calculation formula]

[0154] Q = A · ...

experiment Embodiment 2

[0174] Experimental Example 2

[0175] Adhesive materials of Examples 1-12 and Comparative Examples 1-5 were prepared with a length of 10 cm and adhered to the inside of the antebrachial site of volunteers (n=3). After 2 hours, 1 day, 2 days and 3 days of adhesion, peelability was measured under the same conditions as the adhesion force measurement in Experimental Example 1 above. The peeling direction is the 90° direction. In addition, the presence or absence of pain at the time of peeling was also confirmed. The results for detachment are average, the results for the presence of pain follow the majority opinion. The results are shown in Table 6.

[0176] In Table 6, in the column of peeling pain, ○ means "no pain", △ means "a little pain", × means "quite painful", "Note 1" means "peeling is not possible due to cohesive failure", " Note 2" means "not measurable because the sample was detached from the adhesion site", and "Note 3" means "the sample was broken (repositione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com